So, many of you are aware of Meaker's efforts with massive magazines/clips for flywheels. I was intrigued by the ridiculousness of the project and decided to roll with it. I took the idea behind his Mk-13 and stuffed it in a Stryfe shell, while also incorporating some fire control.

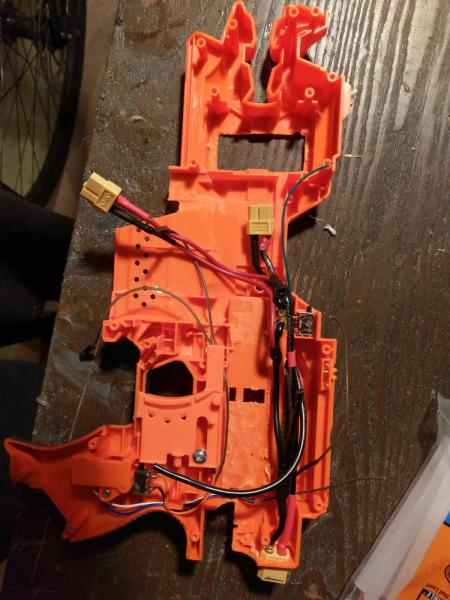

Labelled internals:

The cage has a 41mm gap and is running Blasterparts wheels spun by OG Fangs.

A lot of this is pretty standard flywheeler electrical work. Some stuff that is less obvious:

- There's an integrated Arduino that controls the servo gate. When the trigger is depressed, that little arm inside the clear PVC depresses to allow darts through.

- The linear regulator included in the arduino sucks and wastes a lot of energy to heat when stepping down from the flywheel system's 12v to the Arduino's 5v. So I included a buck converter, which essentially steps down voltage but accordingly increases current so that the power value stays roughly the same (I think 80 - 90% efficiency on this model).

- The push button that controls the servo gate was sourced from a lock IIRC

- Obviously a lot of shell cutting going on here to fit the PVC.

Next I will just put up a bunch of pictures from throughout the build process.

Next some videos of the blaster in action. I'm going to post the second ever firing test first, because it worked better than the first test, and it seems like NH only does embedded vids for the first link.

2nd Fire Test:

1st Fire Test:

https://youtu.be/33D_ze4I4RA

Servo Gate Demo:

https://youtu.be/WI7XwnQfBf0

Closing Remarks:

There is still some work that needs to be done regarding feed issues. I'd like to experiment with different coil materials and wrapping techniques. I also would like to see what overvolting the blower motor does for reliability. I'd also like the provide some reinforcement, particularly by connecting the blower outlet to the pistol grip.

Edited by TantumBull, 29 March 2018 - 05:36 PM.