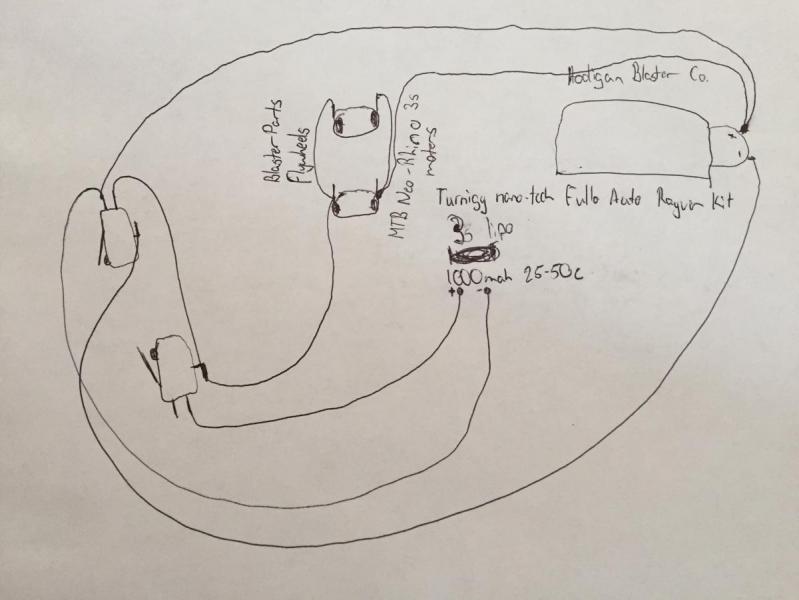

Just finished putting this one together. I was tooling around for something interesting to do and decided to hype up a Rayven with a a new paint job, high-torque motors, and full-auto kit. The most challenging build about this work was the pusher. The original spring rod in a stock Rayven does not attach to the 3-D printed piece so I stripped a Spectre of its slide return tension spring and that seems to be doing the trick.

Materials:

1X Nerf Rayven or Rayvenfire

2 X MTB Neo-Rhino 3s motors

1 X Nerf Rayven Full Auto Conversion Kit (see link below)

1 X set of flywheels (I chose Blasterparts, but any aftermarket set should work)

1 X tension spring

1 X 3s lipo pack (Turnigy nano-tech 1000 mah 25-50c)

1 X male XT-60 connector

2 X 15A Microswitch

16 or 18 AWG silicone wire

Solder

Tools:

Soldering iron

3rd hand

Hot glue gun

Dremel with grinding and cutting bits

Philips screwdriver

Needle-nose pliers

The assembly is relatively straight forward. I highly recommend removing the plastic post just below the handle. This little post makes it very difficult to butterfly the blaster and does not really serve any purpose. I did not have to do very much dremeling to get the microswitchs into place and they are held on with hot glue. I tried a new mounting technique where I put a band of hot glue over the top of the switch and connected it top and bottom to really hold it in place.

I dremeled little holes in the flywheel cage to mount the motors with screws. This step is not required but it does help minimize vibration. The new Neo-Rhino motors work phenomenally and combined with the Blasterparts flywheels provide a really fast spin-up time.

The full auto kit was not too difficult to mount. I highly suggest cutting off the second motor rod that sticks out the back; it does not fit well inside the frame.

The second most difficult part about this build was getting the lipo to fit. I used a nano-tech 3s 1000mah, you can use anything up to that size, I can't imagine anything larger would fit without a larger battery door. As you can see in the picture, the pack is very snugly placed inside the original battery tray. I dremeled out the two sides from the bottom of the tray all the way to the edge where the door comes down. For the door all I had to do was grind down the excess plastic to make it a flat surface and now it fits over the pack with very little discernible bend from the outside.

Because the new pusher for the kit is a little bit bigger, I had to trim some of the shell. This does not kill the aesthetics as it is all covered when the jam door is closed. Also, make sure to pick the right axis with the gear box. If the pinion spins the wrong way, flip the gear box and move the pinion.

Thank you everybody for reading. This is my first forum post and I appreciate any feedback you can give me.

Nerf on and God Bless!

David

Purchase Link:

https://www.hooligan...8emzswkt1amtid1