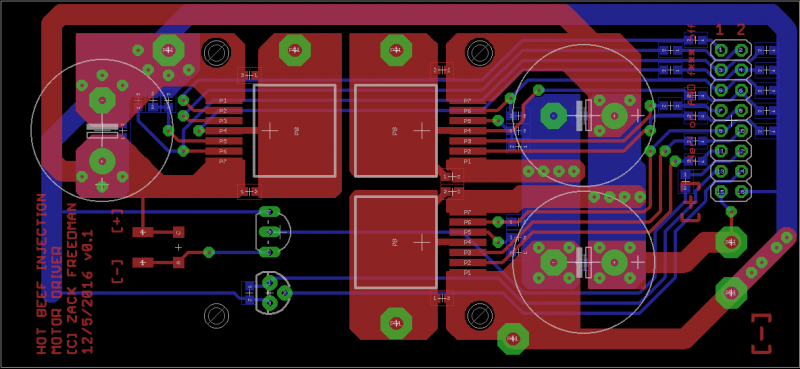

I've been working on an electronic Rapidstrike driver board, and I thought I'd show youse guyses as I build it up.

Working title: The Hot Beef Injection.

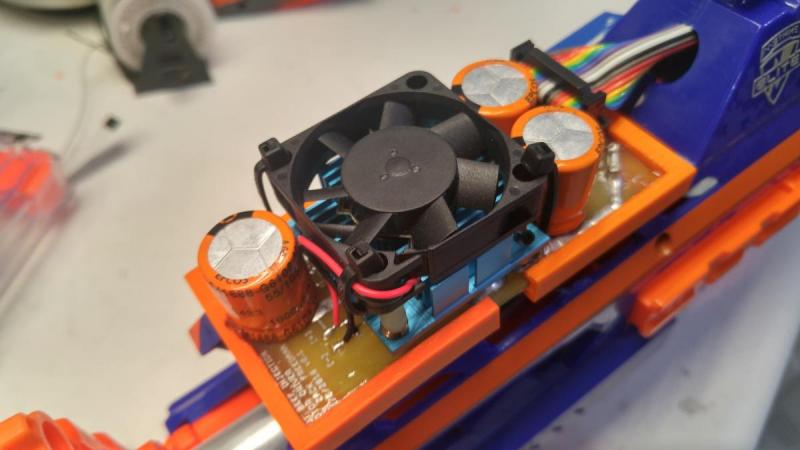

This first PCB is the motor driver. It replaces the Rapidstrike's front tactical rail and enables more sophisticated control than bare microswitches. Each driver is rated to 40A; a heatsink and temperature-controlled fan keep heat under control. This includes:

- Full PWM - the system can ramp up the flywheels slowly, and keep them running at reduced "idling" speed

- Dynamic braking - Prevents pusher overshoot, and lets me quickly halt the flywheels for "stealth mode"

- Sensorless closed-loop control - I can tune the flywheel speeds to maximize energy transfer

- Current sense - For fun. Also detects shorts and breaks for self-tests and safety.

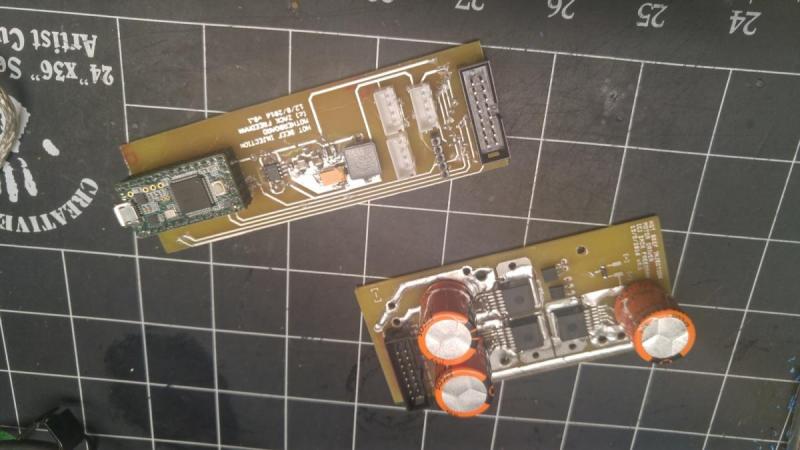

This PCB holds the Teensy microcontroller and has a 5V buck converter for efficient power. This slots into the empty space where the retractable stock used to be. The large connector on the end links this to the motor driver. The other sockets are for I/O:

- Top left: Trigger and rev button inputs

- Bottom left: Two OLED displays connected with I2C

- Top and bottom right: RFID board in mag well to detect magazine sizes

- TBD: Stock pusher endstop switch and mag detect switch

I used a goofy layout, fat traces, and too many vias are because I'm etching these prototypes by hand. The copper clad should arrive soon, so I'll update the post when I etch them up.

Thanks for reading! This is an exciting project, and I hope to finish it by the 17th to bring to CPNO.

Edited by Zack the Mack, 14 December 2016 - 02:55 AM.