Write-Up: http://captainslug.com/pcsr.html

Template Set: http://www.captainsl...r_templates.doc

Partlist: http://captainslug.c...sr_partlist.xls

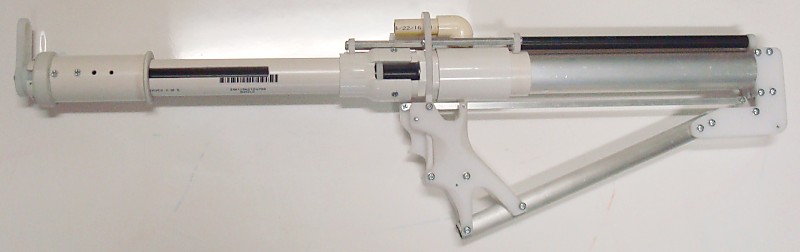

I've made three of these so far. I'm pleased with the ability to break these down without tools, though if I were to make more in the future I would probably advise that the front half be attached with at least one or two screws. Slamming the foregrip back and forth a bunch over a weekend will eventually walk the pipe out of the reducing coupler.

Special Thanks to Aeromech (original design) and snakerbot (redirect)