FOREWARD

This guide is in response to the several emails per month I receive about 3D printing, and it is easier to throw everything out there once than having to regurgitate the same information a dozen times to as many different souls. People unfamiliar with the art seem to forget that it’s not magic, and it’s not the end all answer to your homemade nerfy engineering problems, so whether you are on the fence about getting your first printer, have some ideas about a new groundbreaking 3D printed blaster, or have your own printer and need some advice in parts design or printer settings, here is a condensed summary of all my experiences to get you started. Please keep in mind the information presented here is nothing new, you can google most of this yourself and find similar results, I've never been able to find a single source with all the information I present here; I am no expert, but I do print a lot and have found a nice set of guidelines I like to follow. So think of this more like a noob’s guide to 3D printing. Chime in with your experiences too, everyone’s mileage is a little different.

1. BEFORE YOU BUY

1.1 Things to Consider

Think about your hobbies outside of nerf, how often you will realistically use your new toy, and what other applications you will (read WILL, not COULD) use the printer on. The printed products are often unsightly in their monotone colors; they will not impress your non-techy significant-other and are not really suited for furniture grade applications, however, I have printed cupboard hinges, light fixtures, and small statues with mine, and myriad other non-stress-critical applications are good places to use a printer in your everyday life.

1.2 Types of Printers and their Specifications

These consumer requirements that you have identified will lay the foundations for the specifications of your printer, most notably, the size. There are two figures to keep in mind here. Firstly, the printer dimensions. Self-explanatory, the physical space the printer will occupy on your desk, table, workbench, etc. The second is the print volume. This one is a little bit trickier and will vary based on the type of printer. “Delta” configured Printers will have a print volume that is shaped like a cylinder, and the print bed will be shaped like a circle. Most other types of traditional 3D printers, sometimes called “gantry” or “X-Y” printers will have a print volume that is box-shaped, with a rectangular shaped print bed.

1.3 Types of Printer Filament, the “Ink” to your printer

The two main types of print materials are ABS and PLA, sold as rolls of filament. Basically the “ink” to your printer, and each type has its’ own benefits and drawbacks. I print exclusively in ABS, mainly because of the relatively low melting point of PLA, and I am wary of the spooky materials sciences surrounding plastics as they approach glass transition temperatures. PLA transition temps is 70-80 °C, where ABS is 220-240°C. Read: you are probably fine with PLA, but I just prefer to be on the safe side of things, coming from a region of hot, humid summers. So this guide will focus mostly on printing with ABS.

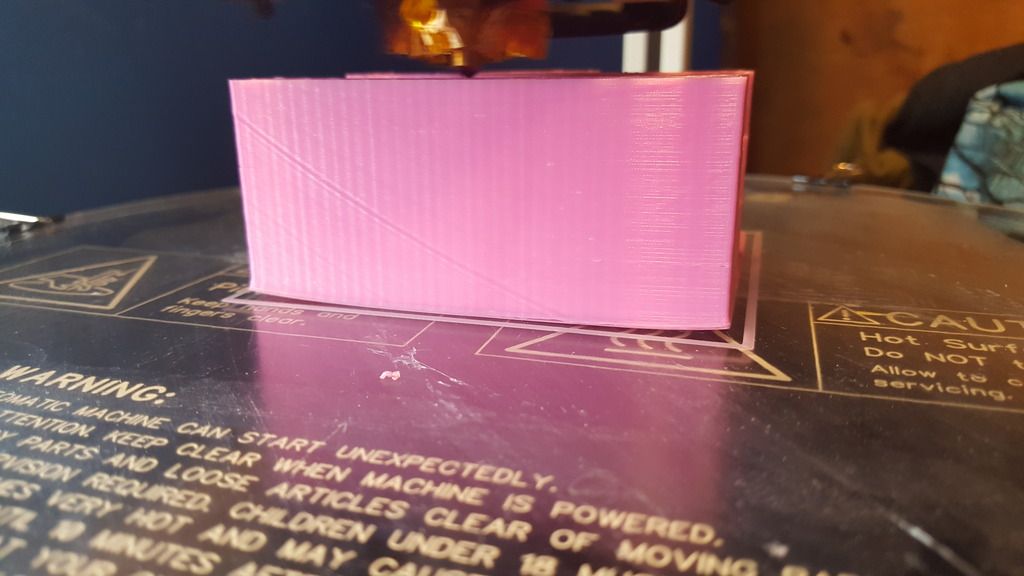

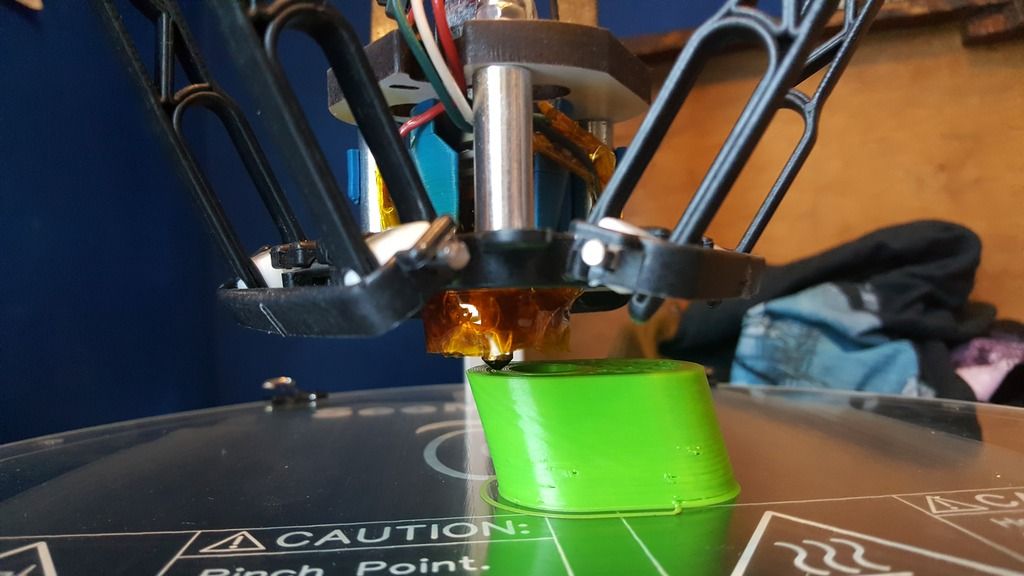

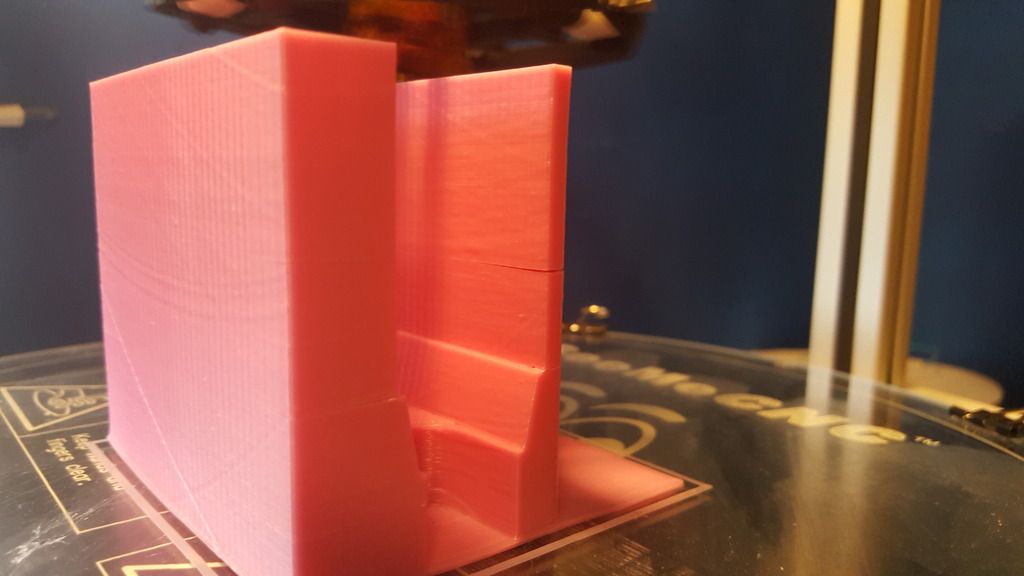

This being said, ABS is a pain to keep under control. It likes to be kept very hot and requires the use of a heated bed and adhesive to keep it stuck down while printing, seen below. Most materials, thermoplastics in particular, like to shrink when they cool down. Essentially, as the top layer of ABS cools on top of a layer that is already hardened, the top cooling layer acts like a flexing muscle, and as it shrinks, pulls up the layer underneath it. This phenomena leads to “curling” of the ABS, causing the edges of a printed part to peel off of your hot bed, and may cause delamination between layers, i.e. the separation of the layers mid-print. No bueno for stresses. We’ll get into the engineering a little later. Additionally, ABS carries more odor with it than PLA. Not necessary a bad odor, but one that you’ll have to get used to should you print in an office or something. Below, you can see the ABS on my part curling up from the bed. The glue was 2 weeks old and I forgot to wash and reapply the glue properly. Luckily, this is only a prototype part and it's not going to be going on any blasters long-term.

For PLA, a hot bed is not absolutely necessary (but still recommended), and because of its’ low melting temperature, is less likely to curl up on you, and produces less odor than ABS, but I’ve heard it is more likely to jam up in your printer, so maybe a little bit more of a maintenance hog. It is also more environmentally friendly than ABS, as it is made from plant based oils. I have far less experience with PLA, so someone else that uses it is free to chime in.

1.4 The Shit Nobody Talks About

There are so many drawbacks and inconveniences to 3D printers, and I will mention a few here and go into depth several of them in this novella. For one, TIME! I am printing a receiver for Nerf magazines for a PCSR variant, I’m only making it as a prototype, yet this 4 x 4 x 3 part is going to take 12 hours to print and it’s only a prototype part 4 layers thick! Damn, there is almost always a better way to do things than 3D printing unless your geometry is incredibly complex.

SMELL! ABS smells up your room. SOUND! I need headphones/earplugs to be able to sleep at night any more if I make any overnight prints. TEMPERATURE! If your print room is cooler than like 80 degrees, your prints will tend to delaminate and peel off the bed. TROUBLESHOOTING! DIY printers means DIY fixing. If parts break, you have to take the initiative and reverse engineer some of the parts/ go back into the manual and figure out what’s wrong. This experience was a crash course in electronics, mechanics, and stress application. Luckily the Rostock has a great instruction manual. LIGHT! If printing at night, the display is backlit and I have yet to modify my code to turn it off. SAFETY! We’ll get to that in a minute.

1.5 Pricing

All of these factors, maximum temperatures of the hot-end, type of printer, size of printer, the inclusion of a heated bed, will all affect the cost of your printer. I have seen some for as cheap as $200. Some are as expensive as $3000 for consumer models. Some are pre-built, other have some assembly required or come as kits, and hell, if you are good enough you can literally build your own from zero (Read: You probably aren’t good enough to build your own from zero.) I chose the Rostock Max V2, a kit-build, with everything included in the box, just nothing put together. The wiring, mechanical assembly, soldering, tuning, and troubleshooting, and troubleshooting, and troubleshooting was all left to me. If you want a fun project, and are confident in your building/tinkering skills, I say go for it. If you just want to get printing already and can’t be bothered with the VERY likely screw-ups of DIY, then a pre-built one might be the way to go. Market price for my printer is $1,000 for the kit, but because I put it together myself, I have the print volume of a printer twice as expensive.

Being builders of homemade blasters, most of us reading this are probably very mechanically minded individuals. If electronics and software aren’t your thing, I’d say don’t worry too much. If you have a kit build, read through the instructions and jot down any questions you have, find community resources, reach out to the company, google how to make proper connections, etc. I had no problems with my Rostock instructions, they were very thorough. As for software, it is my understanding that most kit builds operate on software that can be downloaded from a community site. For my printer, I didn’t write a single line of code! It was downloaded from an open source webpage for 3D printers. This will probably be the case with almost any other kit or pre-built printer you come across.

One last thing to consider is the community of people surrounding your printer. Is the company reliable and trustworthy? What do the reviews say about this printer? Are experiences generally positive? What do these guys use theirs for? Feel out the market for something you like.

It’s all very specific to each person and is a decision that is ultimately your own to make. This is where I cannot help you. Research the shit out of printers and find one that you like. Hell, go on craigslist and see if you can get a used one for cheap. Fixing a broken printer or building it from a kit really gives you an idea of the things’ personality. It’s hard to explain. But it feels right.

2. THE GOOD STUFF

2.1 Terminology

I guess now would be a good time to introduce some of the common vernacular we use round these parts, if things weren't technical enough for you yet.

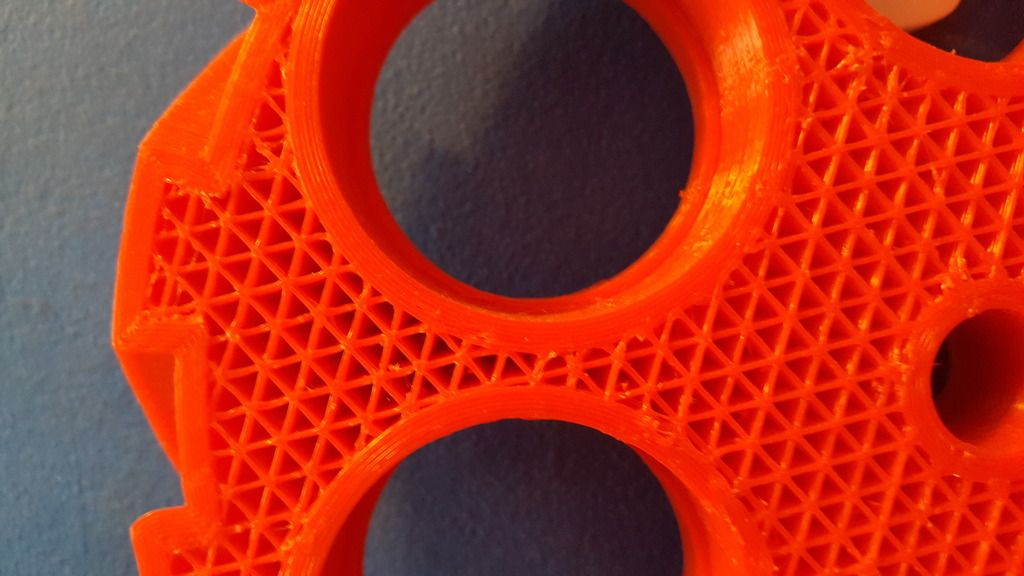

Below is a half-finished part that I hang on my wall to demonstrate some of the physical phenomena of 3D printing. I have referred to "layers thick" a few times already, and this is precisely what I am referring to, more correctly called "perimeters". Generally, the more perimeters you have around the outside of your part, the sturdier it will be. You can actually count the number of perimeters I have here, This one is 6 layers/perimeters thick. When I say "layers thick" this is what I mean, as opposed to "layers tall" or how many individual, horizontal layers make up your part (the number of cards stacked up in your deck).

The second quality to note is all the cross hatching hexitriangular nonsense you see in between the perimeters. This is called "infill" and basically allows for the print to be completed faster than if it was a completely solid part, and still keep the finished product relatively strong and lightweight. The infill basically forms many little "tubes" that follow the layers vertically upward, the view you see below is a "top" view, so the print bed was originally on the underside of this part. Not much to say here, except I like to keep my infill about 40%. This means 40% of the inside volume is occupied by the infill filament, and the remaining 60% is air. You can go anywhere from 0 to 100% infill, but at some point diminishing returns kicks in, and I supposed if you wanted to make a totally hollow part that's how you could do it.

My Rostock is a delta style of printer, so these next parts may not look exactly like they do on other printers, but the principles and functions are identical. Below is a photo of the hot-end printing a part, now using green filament. The "hot end" is the general name for the entire assembly that heats up the solid plastic filament to a hot and sticky goo. That whole big thing. The nozzle is the tiny little brass thing at the very bottom making contact with that part that lays down the next layer. Those wires you see are hooked up to two heating resistors buried inside the hot end that heat the whole thing to 235 °C. If you've ever hooked up a resistor to a battery, you know it gets hot. Same idea here. All that orange cellophane looking stuff is actually a special heat resistant tape called Kapton. Keeps everything in place and doesn't melt until like 400 °C or something ridiculous like that.

2.2 Design of Parts

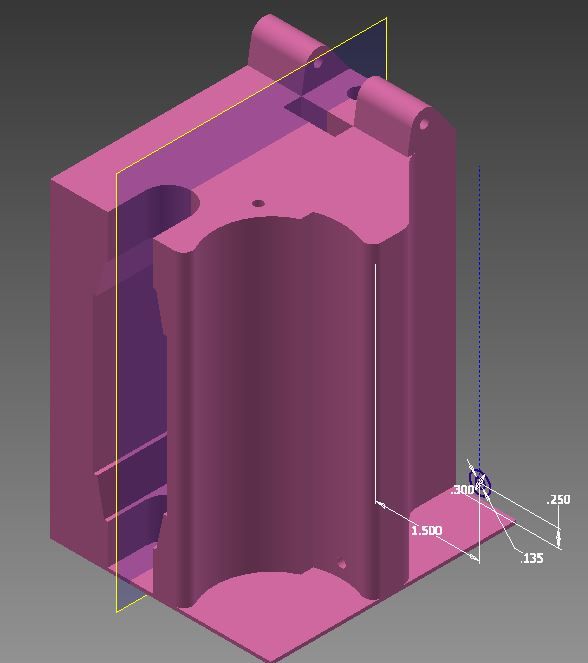

So you have your printer and now it’s time to design your own parts. This step is optional, if you just want to spit out pre-made parts there’s nothing wrong with that, but this is my hobby and I’ll cry if I want to. Good parts design is crucial to having printable components. I use Autodesk Inventor and save parts as their solid parts, as well as .stl, this seems to be the format that 3D printers like.

Remember that 3D printing is really just like stacking a deck of cards, one by one. Each card is only a few thousandths of an inch “tall”, but several inches long and wide. One card placed on a table is almost two dimensional. Stack 52 cards on top of each other, and look at that, you have a tangible 3D rectangular prism shape! Think of each card as a “layer” of the print; it may not be a rectangular shape, but you get the analogy.

Each layer is supported by the layer underneath it, or at least that’s what we are shooting for with parts design. I’m going to give you some examples of good and bad parts right here.

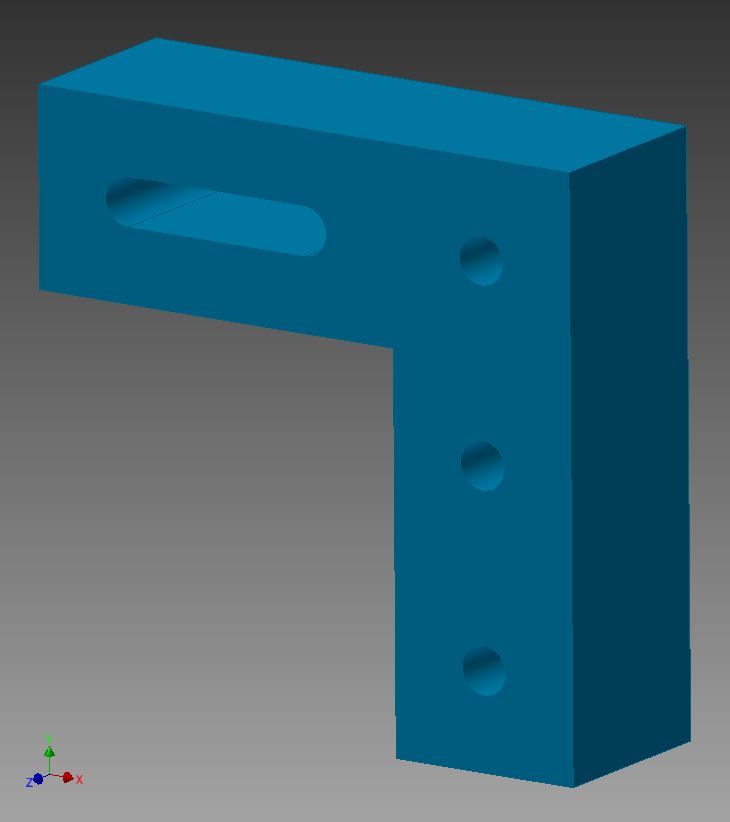

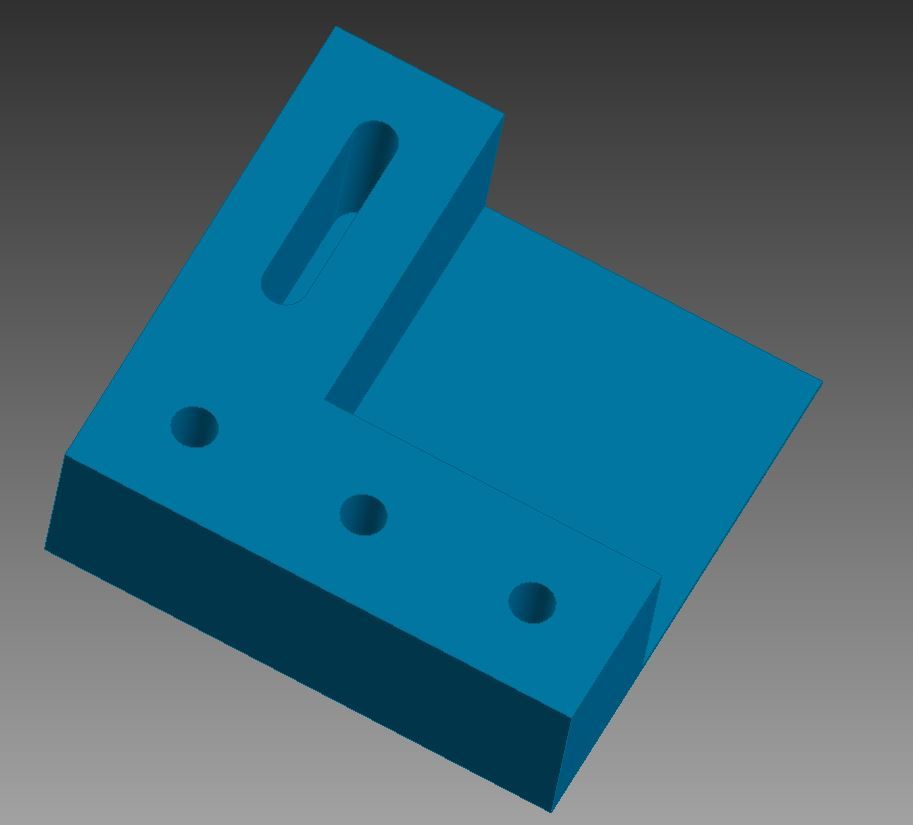

Let’s say I want to make this bracket shown below, measuring 3 inches tall, 3 inches wide, and only 1 inch deep. Is this a good orientation to print it? I.e. should the face currently on the bottom be what’s touching the hot bed?

No. mostly certainly not. The Top-Left arm is not supported by anything underneath it. Remember the deck of cards analogy, now imagine each card is not rigid, but rather made of jelly. Each card is supported by the layer beneath it. With nothing to hold up that first layer of the bottom of the arm, the hot filament will fall right to the ground as it exits the hot-end. It doesn’t cure instantly, in fact the filament takes several seconds to fully cure/harden/cool. Like squirting elmers’ glue out of the bottle, it becomes a solid eventually, but it takes some time to get there first. Our “glue” dries faster, but it is still essentially a liquid when it’s squirted out, all the same. My rule is that every “arm” like this must have a lower face that is at least 25° away from horizontal. I think Kane’s rule is 45°, like I mentioned, everyone’s is different.

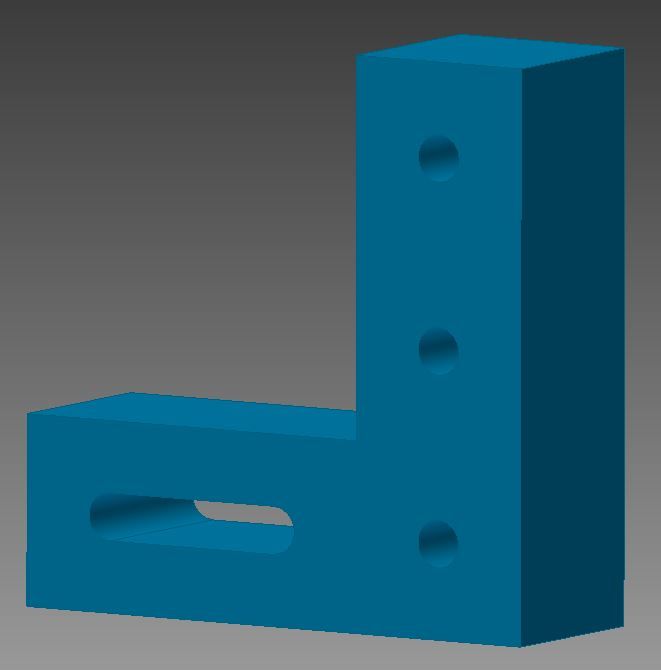

So we have two options here: Fix the part by applying the rule I mentioned above, or change the orientation of the part so another face is touching the hot bed. I will opt for the second one this time around…. So is this part “printable”?

Hmmmm, I’d say it’s better but still not ideal. The channel on the bottom left part is left unsupported again, and will probably sag or produce a sloppy couple of layers. The circular holes shown typically aren’t as problematic because even though they are technically unsupported from directly below, they sort of build up to that point of being unsupported, and much like an arch bridge, provide enough support while it’s being printed to be not of major concern until the diameter exceeds maybe 2 or 3 inches.

So what do we do here? There are two options: Either change the orientation again or allow the use of support material on you printer software. I don’t like support material mainly because it seems to promote the use of poorly designed parts rather than making parts that are honestly better and stronger to begin with. Plus, it adds more steps to the end process of finishing off the parts, and leaves jagged or pointy bits that are uncomfortable and unsightly.

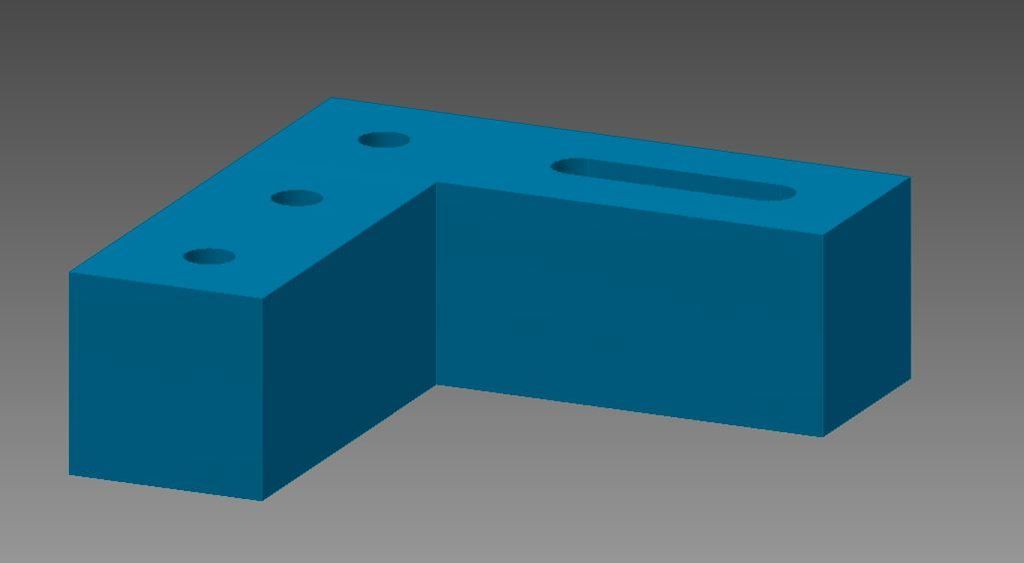

On this next orientation change, again we are left with some options. Either rotate the part again, so the channel is vertical, (which would work because it’s now essentially a circular hole on the top that will be supported well enough as previously mentioned,) or turn it on its’ side. This second option is probably the better one. Why? Well if each layer is only 0.2mm thick, the general rule is that it will always take longer to print vertically than horizontally. So if you can keep your parts short, keep your parts short. Let’s turn it on its’ side….

This is probably the best way to print this part, with one last little change I want to make. The first layer of your print is the most important, as a good bottom “bed” layer will ensure the best adhesion to the bed for the duration of the print. Small little details are not usually good for this, as they are likely to get knocked off during that crucial first layer of print. What I usually do for complex pieces is make a “raft” for the part that covers all the holes and smooths out the bottom face of the part. Below, all I’ve done is drawn a square bottom to the part and extruded it 0.030 inches, or about 4 layers. This is easy enough to remove with a knife or drill bit for the holes, and makes sure there is good contact with the hot bed. It adds some time to the print, but it helps with adhesion and therefore final quality in my experience. In short, the first layer of your print should always be kept SIMPLE. No holes, no weird wavy or jagged geometries. Keep it simple. A square, a circle, a rectangle.

Another thing to keep in mind is the size of the part, or thicknesses of peninsulas on each layer. For example, the part shown below has a crack about midway up the far wall, because it is only about 1/4 inch thick at that point. Thin walls have the same tendency to curl up, but don't have the interlayer surface area to hold the top layer down like thicker layers. Something to keep in mind while designing, and just another reason 3D parts often look blocky or bulky. Also, a crack is visible on the close wall, right at the transition from angled to vertical where the magazine will eventually sit. This is due to a sharp angle transition, even one that small leads to a big stress concentration. This is why it's a good idea to make "prototype parts" first, that will print faster than the final part, and will reveal weaknesses in the design that may not have been apparent initially.

2.3 Principles of Engineering

Good parts design is essential to parts that aren’t going to fail in the field. I can tell you firsthand that just making the part a few layers thicker isn’t always going to solve your problems. The first generation of pullbacks were embarrassingly not up to the task of full on outdoor nerf wars. That being said, these failures have taught me a good deal about the weaknesses of 3D printing, and the amount of working around you will actually need to do to make a sturdy and robust part.

The first thing to remember is that these are literally individual layers that are sort-of-not-really adhered together. The filament extruding from the hot end never gets to a truly molten state, and rather just reaches a sort of glass transition temperature. The filament while being extruded gets squishy and sticky, but the layer beneath it is still fairly cool. A chemical bond is never actually formed between the layers, and the rule of thumb is that the 3D printed strength of an item is 30 percent that of an extruded/ injection molded part. Yeah. Less than a third of the strength. This is where people seem to have issue. 3D printing is not the golden goose egg to homemade blasters. Like a drill press, or a scroll saw, or a belt sander, it’s just another tool, and you don’t NEED any of them to make a banging Christina Hendricks (or Chris Hemworth, depending on your mood) homemade. Don’t forget that. You can’t just print anything you want willy-nilly. Go ahead, try to print a sentinel shell or something. It will literally fall apart. This is why the printed blaster parts we are familiar with are often thick or goofy looking. They NEED to be that way to even be a fraction the strength of their counterparts.

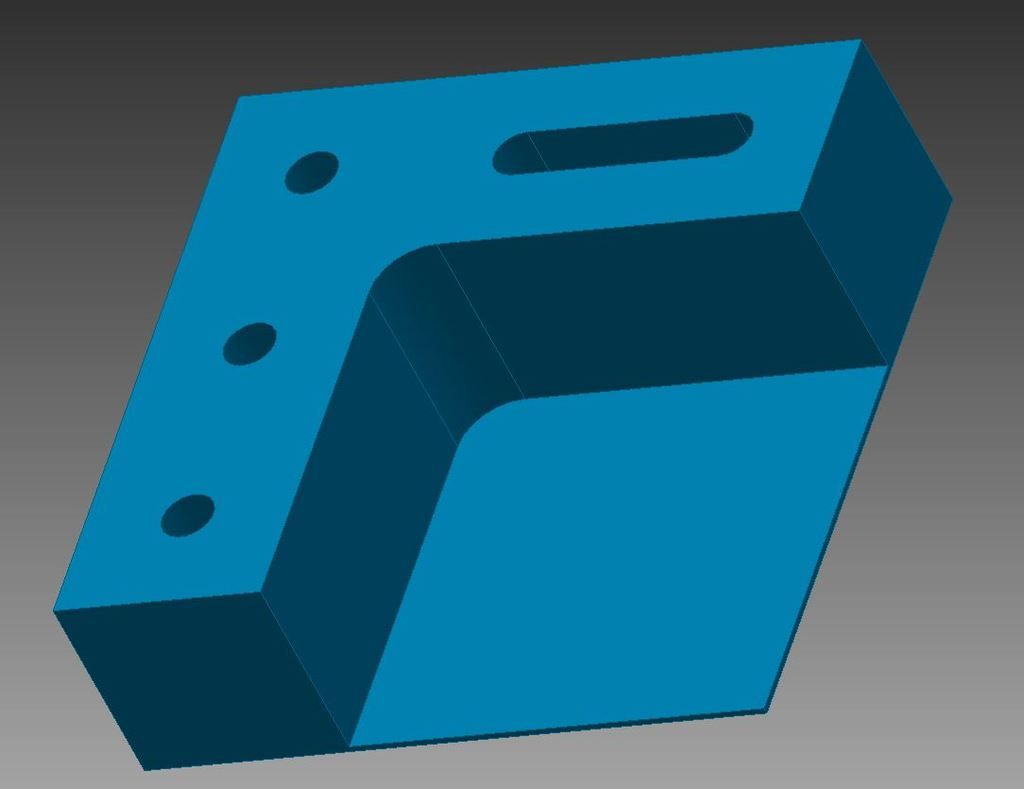

Morever, think of the stresses on the part. The interlayer surface planes will always be the weakest link in the part. Pulling apart the layers is pretty easy for example (tensile stress), but the parts handle COMPRESSION stresses very well. I’ve actually printed a set of longboard risers which are holding up with no problems because they are sandwiched between the metal trucks and the wooden deck, and are always in a state of compression. The PCSR catch shown below holds up well because the interlayer forces are largely compressive with a bit of shear. Reason out the stresses. Draw a free body diagram if you need to to visualize the forces. FEEL the stresses in your parts. An extra five minutes on paper will save you like seven hours on the print.

Think about the bearing stresses too. The force that occurs when a screw or bolt or rod is put through a hole in your part. It’s going to want to split your layers apart, whether pushing apart the layers like an axe, or prying them apart like a crow bar. Distribute these stresses wisely. Think 4 screws are good enough? Use 6 or 8. Be generous with your factor of safety. If your stresses are directly in line with tensile forces, there is a good chance that your part will be overstressed. If you have high stress components, either print the layers at an angle to the forces (to mix shear and tensile stresses) and ensure all your sharp corners are rounded out. Filet everything you can get away with. Sharp corners are particularly pronounced in 3D printed parts. Layers will almost always separate on a sharp transition. That first example we did REALLY should have a quarter inch filet on that inside corner….

That’s better. Additionally, below is a comparison of the original pullback handles, with the mk V and up handles, with gradual filets on the inside corners, and a completely redesigned shape, with layers printed 8 degrees offset from the normal of the applied forces. Left is old, right is new.

3. PRINTER SETTINGS AND SUGGESTIONS

3.1 Technical Stuff

To reiterate, I use a Rostock Max V2 Delta style printer. My hotbed is borosilicate glass coated with 1-2 layers of purple glue stick glue, applied when the bed is cold. Wash this off with glass cleaner and replace with new glue every 6-8 prints, or whenever the ABS starts to peel from the bed. This hot bed is typically set at 108℃. Anything below this seems to peel off the bed too easily during printing. My hot end is a 0.5mm nozzle set to 235℃. Anything below 225℃ seems to result in delamination, or peeling, between individual layers, something that is highly unwanted in stress bearing components. EDITTED 9/26 for better results.

To combat delamination, I recommend the use of an enclosure. This can be as simple as a box made of wood or plastic, or a large storage container retrofitted with a small window and door. For enclosure heating, I have used incandescent light bulbs that I scrapped from an old desk lamp, and integrated these into the enclosure. There are certainly better heating options, but incandescent bulbs are cheap and can be found almost anywhere, and provide enough heat for my purposes. The enclosure doubles not only as a means of keeping heat in, but keeping the cold out. It suppresses the noise of the printer somewhat, and blocks the cool air of a fan or air conditioner or an open window which may provide inconsistent or accelerated cooling of your print layers.

I use Matter Control as my printing program. I print a MINIMUM of 8 layers thick on all components using the aforementioned 0.5mm nozzle, with an infill of 40%. For stress bearing components such as the Pullback under stock pull-bar, I use 10-12 layers thickness, and for rainbow catches, I print at 100 layers thick, to make sure that there is total fill on each layer. Speaking of, my layer height is 0.20mm. Smaller print layer heights have the problem of curling up on overhanging geometry, such as the back end of pistol grips, but once again, everyone’s experience is different. It’s always better to print a few more layers and wait a little longer, than rush the print job and have parts break on you in the middle of a war. Printing more layers will make your parts stronger, but if your part is poorly designed, it will merely be a bandaid on the problem.

For components with screw-holes, invest in a tap wrench with appropriate tapping bit. Tap the first ⅔ of the hole and let the screw tap the rest itself. This gives you a good adhesion to your part while preventing the part from splitting. If your part begins to delaminate or split, and you cannot be bothered to print another, I’ve found it best to apply some superglue or epoxy to the damaged area.

3.2 Community Input

Meaker suggests not to run PLA and ABS through the same nozzle or printer. This makes sense. If PLA melts roughly 150 °C lower than ABS, any ABS chunks left in a nozzle from previous prints would remain solid, and block up the printer.

Draconis recommends using ABS pipe weld to repair ABS parts. I've never tested this before but this really seems like a good idea. I just hope the results don't mimic those of acetone. Again, everybody has a different experience with this stuff, and I'm only here to point you in the right direction if I can.

3.3 Safety

You're working with really hot things. Should be obvious but don't touch the hot end or the bed. Even if you turned it off, it stays hot for a couple of minutes. Don't be an idiot.

Everything I have read suggests that 3D printing is overall safe. I understand tiny nanoparticles are produced, as well as a negligible amount of hydrogen cyanide. As it stands now, I largely ignore these issues, but you shouldn’t. A good idea is to print in a well ventilated area, in a relatively large room, windows open, that kind of thing. My eventual goal is to have several printers running in tandem in a large closet or enclosure with a proper ventilation system, ducts with fans directing air out of a window would not be something difficult to accomplish, and would be rather modular when I get my first apartment that would not take kindly to me tearing out walls. When I have a proper workshop, ventilation will be a real thing.

Fire safety is the real big deal. Google 3D printer fires and things get not-so-pretty. Again, my ideal long term setup is to have a simple Arduino controlled CO2 fire combat system within said enclosure to starve the fire. If you are not a mad scientist by the light of a full moon, there is another product for mortals to invest in that already exists on the market. I have yet to test it out, but it seems like a good idea. It’s called smoke signal; I’ve linked it at the end of this article, and I will make a review once I have it properly installed. It only shuts off printer power, and doesn’t actually put out a fire, but it does prevent the spread of an electrical fire. In conjunction with a CO2 flood from the aforementioned system, this could be a very effective tool in fire prevention.

All this being said, do not leave an active printer unattended! Always be within earshot of your printer, and if nothing else, stick a 5 dollar smoke alarm to the top of your printer! It may just save more than your new toy.

4. THE END

Have more to add? Leave a comment and I’ll add it in. If I ever receive a nooby 3D printer question I will respectfully refer you to this article to read in it's entirety. Think some advice is faulty or inconsistent with your own experiences? Write it in a comment. Think this article sucks? Roflcopter spend 6 hours of your weekend and write a better one. Anyway, thanks for the read and putting up with my dry humor.

Nerf on you beautiful technologists and engineers and tinkerers and athletes and artists. I hope this helps you in some small way.

-Aeromech

Additional Information Provided by:

Meaker

Draconis

Resources

ABS vs. PLA

http://www.protopara...r-3d-printing/]

ABS tips

https://www.matterha...inting-with-abs

Rostock Max 3D printer Instructions

http://download.seem...-2ndEdition.pdf

3D Printer Fire Prevention Device

https://3dprint.com/...-3d-print-fire/

Edited by Aeromech, 26 September 2016 - 05:35 PM.