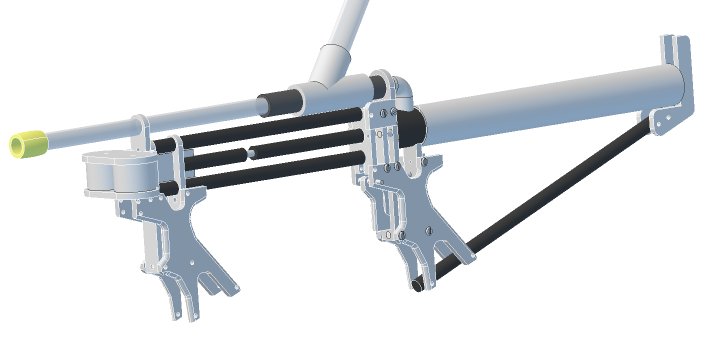

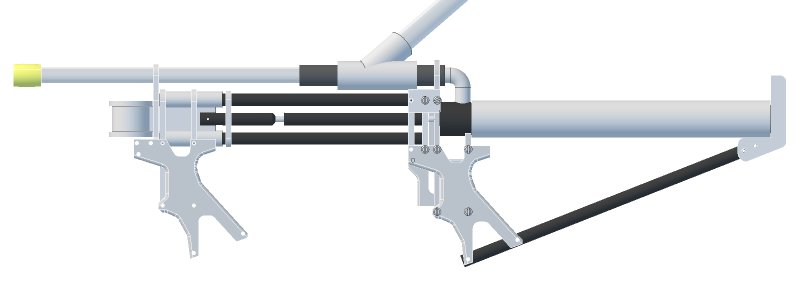

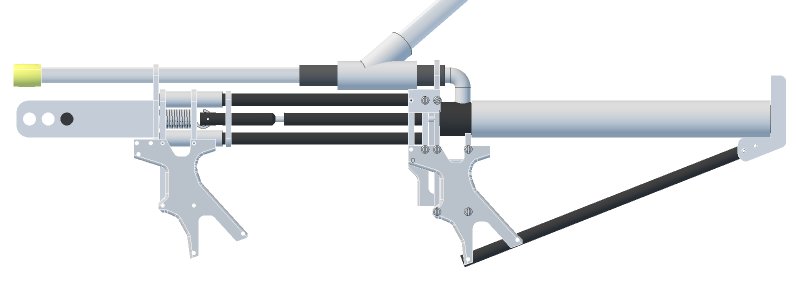

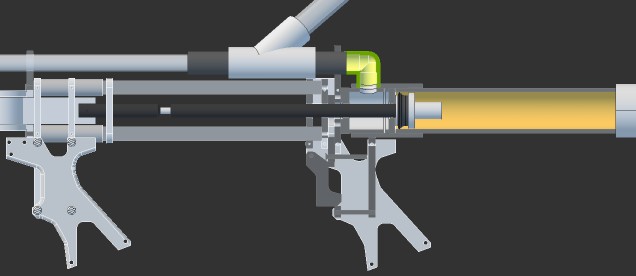

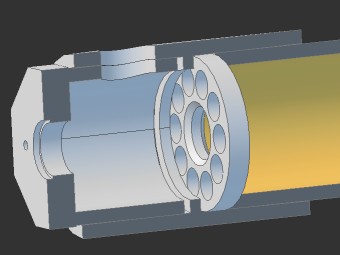

I was thinking more like a test-bed that would allow for 1-to-1 comparison against a [k26] or [k25]. Here's my concept for a horrible chimera of a PCSR, ESLT, and +bow. The foregrip slides on the two guide rods to push the plunger rod backwards into the stock. The nicest feature is that there are no slots to cut in PVC.

The catch is the +bow Rev.3 type, just working backwards so I can avoid have a linkage. The redirect piece is mounted to the back of the grip frame, which means that the frame piece itself is retaining the o-ring or shaft seal that the plunger rod slides through. The dual constant-force springs are in an optional cassette at the front. The back of the plunger tube still has room for a full-length [k26] or [k25] should you want to switch to one. Or you can add a trimmed one of either to act as a plunger "booster".

And the solution to the "No Wars Near Me" problem is to host one yourself.

I see what you did with the mock up rifle idea, and could definitely see having the swappability of the 2 springs being a good idea

As for hosting one myself, it's something to consider.