Alrighty, so here goes.

I'm almost certain there have been many similar renditions to this, but im not sure if I've found anything exactly the same, please correct me if i'm wrong, and if so I apologize.

This write up is also going to be less-than great, because this entire blaster was made with eyeball lengths and such, and there was alot of trial and error, so again i apologize.

The catch works basically like a rainbow or R3L style catch, with some different stuff i made up, and the whole blaster is made from stuff i found at my local ace for around 30 dollars or less, aside from the [k25] spring but this design can be applied to pretty much any spring length/power within reason.

I used pretty much basic hand tools aside from a power drill and a heat gun.

You will need:

2 - 1" to 1/2" reducers

1 1/4" PVC

1" PVC

3/4" PVC

1/2" PVC

3/4" threaded pvc plug

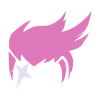

1/4" by 1/2" U channel

bunch of different 6-32 screws

E tape

Main spring

strong-ish catch spring sized spring that fits around a 6-32 screw.

a "CAN-GUN" spray paint sprayer (http://ecx.images-am...nL._SL1440_.jpg)

Plunger:

Take your U channel and cut it to the length you want your plunger rod to be. a bit longer is probably better because it can always be cut down later. I used somewhere around a foot.

Wrap the end in E tape til the edges fit snug inside the 3/4" threaded cap. I used a threaded cap bc the inner diameter was a bit snugger to the u channel than anything else.

Screw it on

Make a snap style head and screw it on and slide your spring on for now.

Spring Rest:

I used about a 1/2" length of 3/4" pvc forced inside about an inch of 1" pvc wrapped in a bit of etape so it's centered in the plunger tube. This allowed my [k25] to rest on the 3/4" pvc and the 1" keeps it centered while still have enough room for my u channel plunger rod to freely slide through.

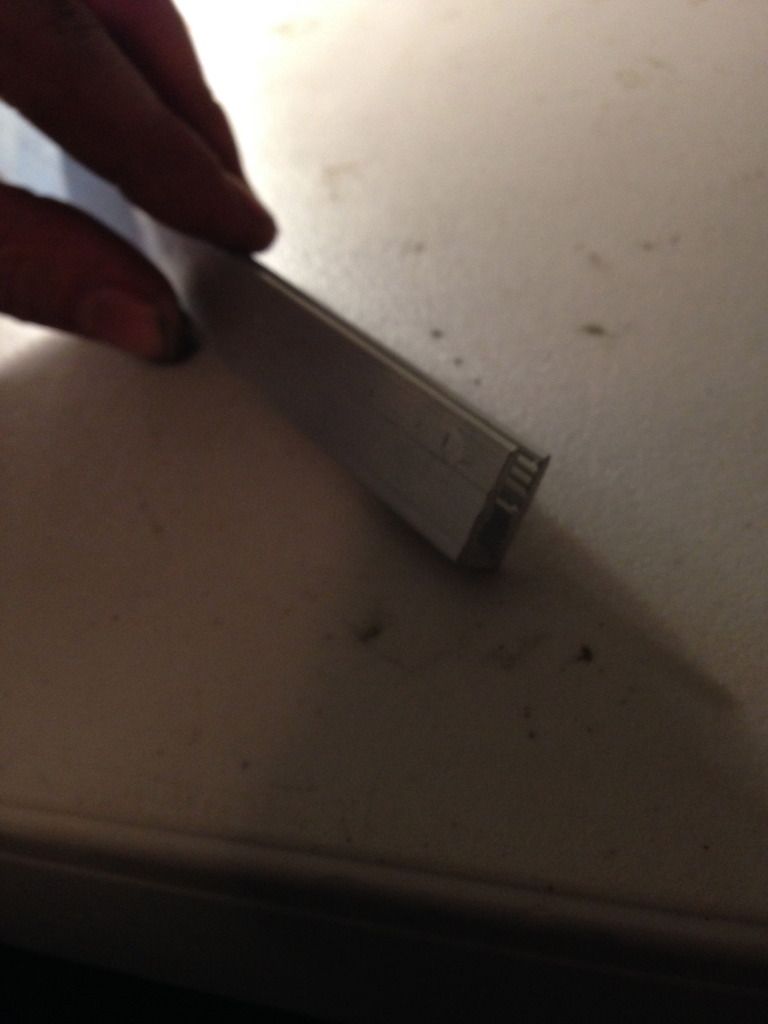

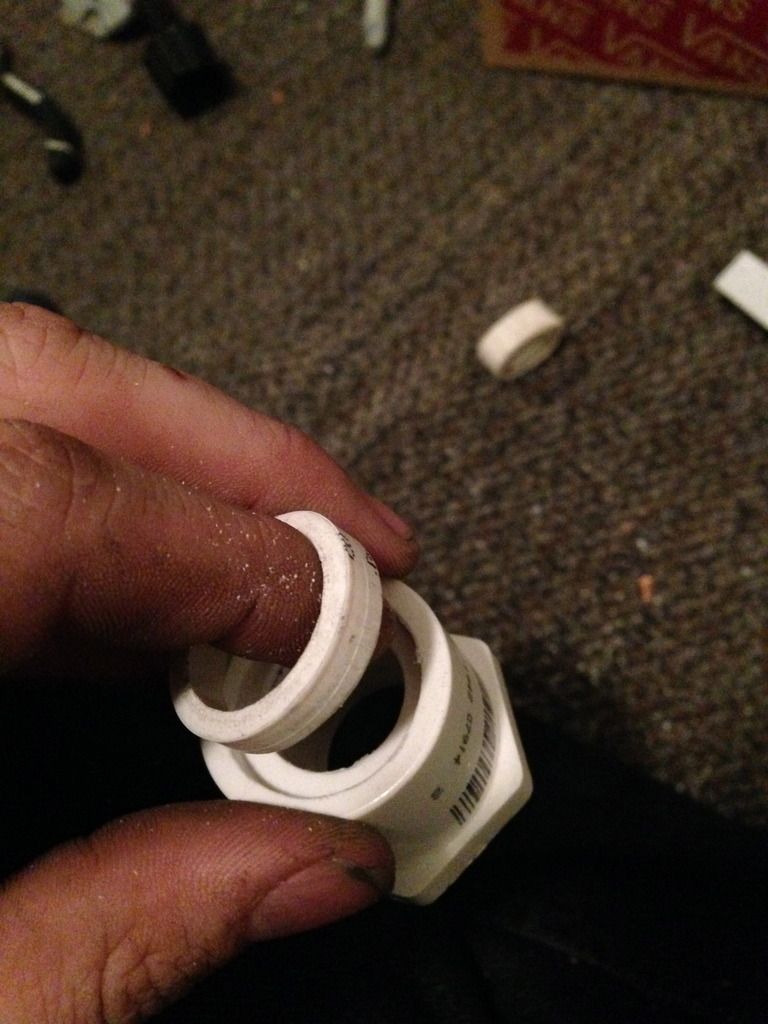

Catch ring:

Take about a 3/8"-1/2" length of 1/2" and 3/4" pvc and make them fit inside of each other.

Heat up this ring, i used a heat gun. stretch it around your u channel so it has as squarish of a shape as possible and slides freely around your u channel. You may have to file the inside a bit once it cools down.

I ended up having to cut off the bottom so the catch had more space to fell into the catch notch on the rod. Because the 3/4" ring wasn't as tight without being full i super glued it to the inner ring. I also ended drilling a small hole in the top of the catch and putting a set screw thru both layers of the catch, which i unfortunately don't have a pic of.

Compress your spring as much as you can with the spring rest over top an mark where your notch for your catch should be and cut.

End cap:

take your 1" - 1/2" reducer. There's a lip on the back side, a tiny sliver of 3/4" pvc and make that lip flat so your catch has a back plate.

Body:

Take your other reducer and wrap er in tape and super glue/goop/etc to seal it up in you're 1 1/4" plunger tube. put a screw thru for support same as a snap and every other homemade pvc spring.

Take your plunger/spring/spring rest/cap and measure out how long your plunger should be.

Leave less than a millimeter of space between catch/rest/end cap so the catch can move up and down but not forward/backward. Cut your plunger tube to length, line everything up again, and drill holes for the end cap and spring rest.

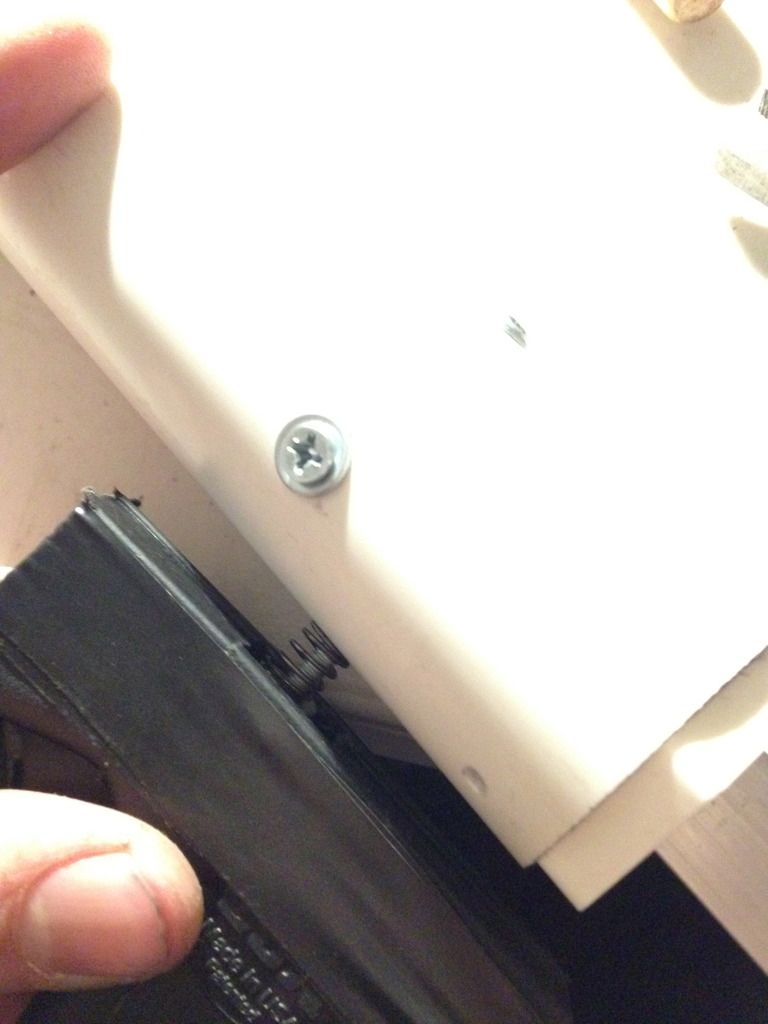

Put your plunger/spring/spring rest in and screw the rest in. slide your catch around the rod and make sure it's flush against the spring rest. Drill an 1/8" hole thru the bottom of the plunger tube and reem it out so your screw can slide freely, and drill an 1/8" hole in the bottom of your catch but do not reem it. take a 6-32" screw, a few washers, and your catch spring and screw into the bottom of your catch like so:

(Note: I ended up using a longer screw and 4 or 5 washers instead of the short screw and 1 washer pictured)

Drop your end cap in and screw it on. I found 1 screw is more than enough cause there's not any real pressure on it.

Handle:

take your "can-gun" spray paint handle:

Split it apart, pull out the trigger:

Make it look like this:

Take the handle and make it look like this. Don't mind that extra cut in the middle i screwed up and ended up having to glue it back together, no fun.

Cut a square in the top:

Screw head/washers/spring should move freely through the hole:

Drill some holes for zipties:

Throw some hot glue on top and slap her on and line it up, then tighten zipties,+more hot glue on edges for good measure.

This ziptie keep the bottom of that part from splitting under pressure and keeps the trigger from swinging to far forward.

Wrapped the handle in E tape to stiffen it up a bit. would probably benefit from being filled with hot glue, resin, epoxy putty, etc, but I didn't do any of that and its still plenty sturdy, I just think it would feel a little nicer filled. Drill an 1/8" hole through the end of the plunger rod, reem it a wee bit, and put a 6-32 screw with some washers on it and a nut on the end for a handle to pull back.

In conclusion im pretty satisfied. It works flawlessly so far and was cheap and relatively easy to make in a few hours.

I will likely be posting revisions/additions as i make them/fool around a bit more, as i just came up with this like 2 days ago and made it today.

Let me know what u guys think, good or bad, or if this has been done, etc.

Thanks

~Holter

Edited by Holter, 03 March 2016 - 12:26 AM.