I had some brushless motors lying around so I decided to make my stryfe run on three phase AC. The motors I used are DYS 1806 2300 kv motors, which have a 2mm shaft and can run on 2-4S lipos. I also set them up with one 30 amp speed control, and an arduino using a potentiometer to control motor speed. The velocity on a 3S lipo exceeds 100 feet per second and the motors run almost silently. I will have more updates as the project moves on, but I have only completed preliminary velocity tests on 3 cells. I still need to figure out a way to house the arduino.

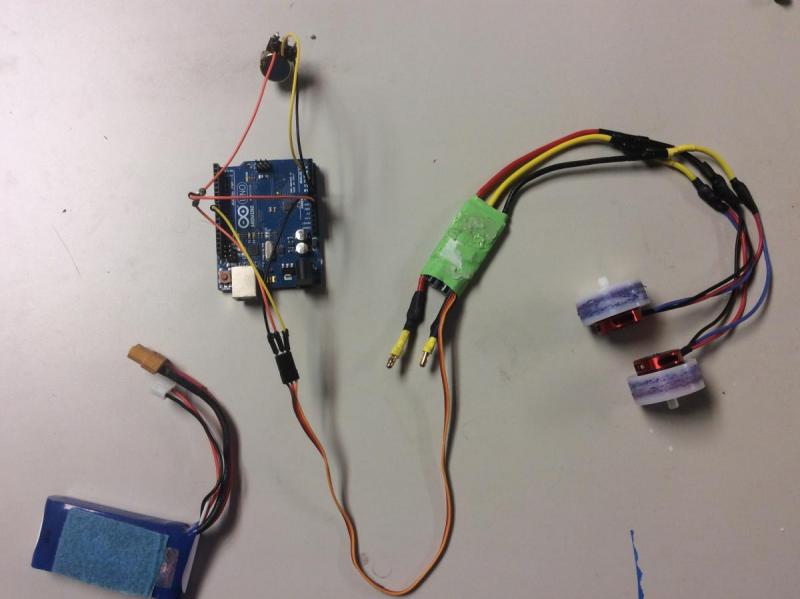

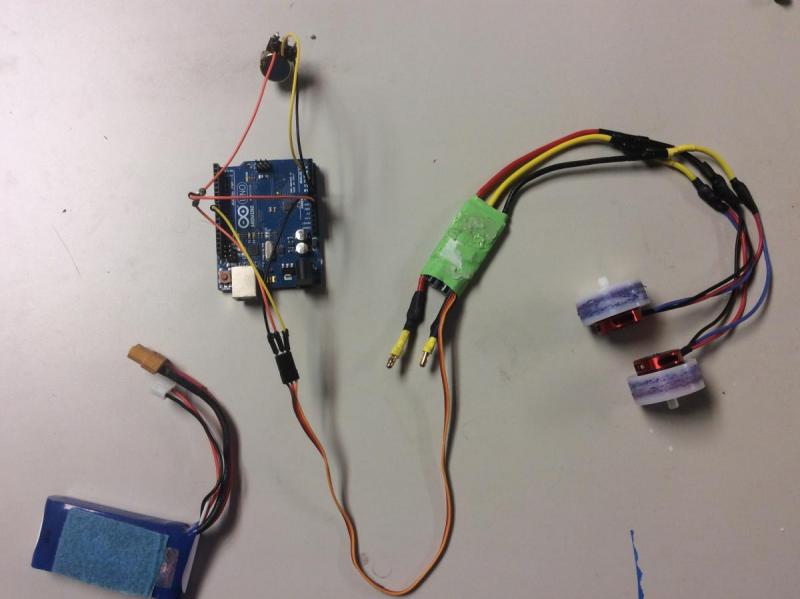

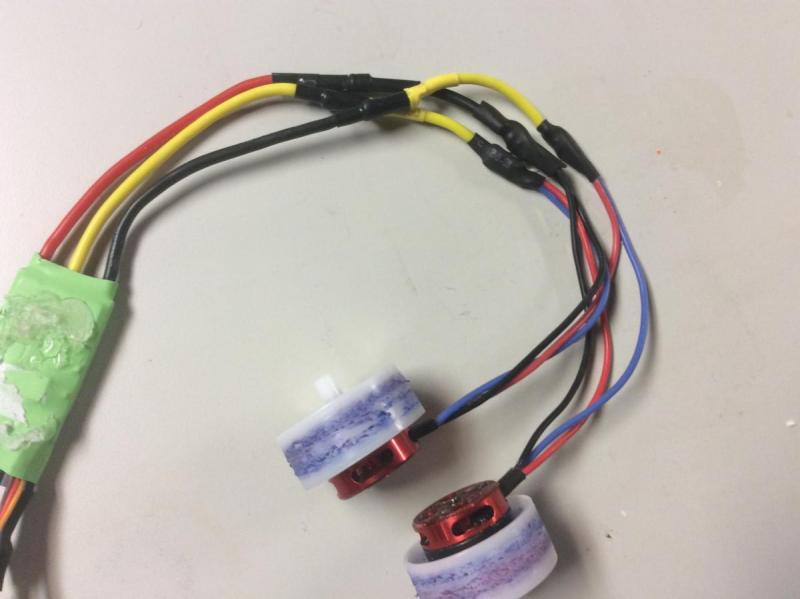

The test circuit for the electronics

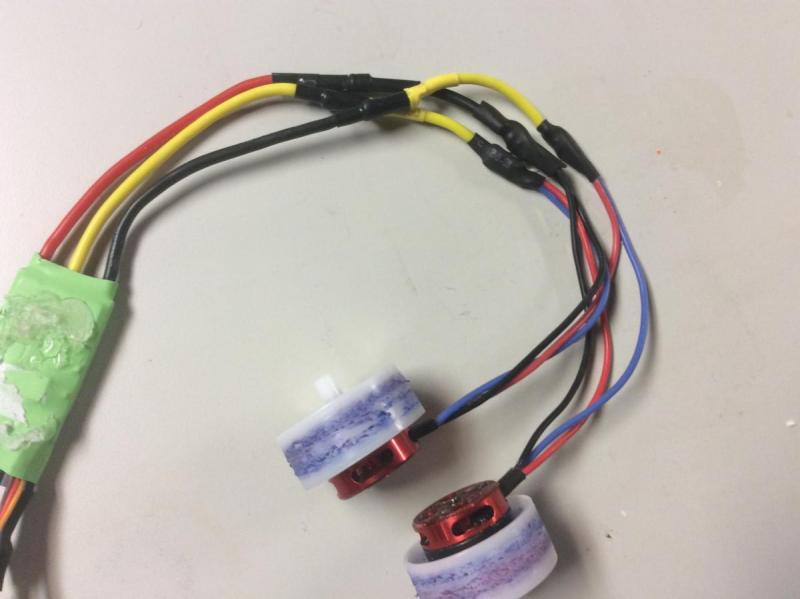

Arduino pin outs

I am running two motors with one ESC

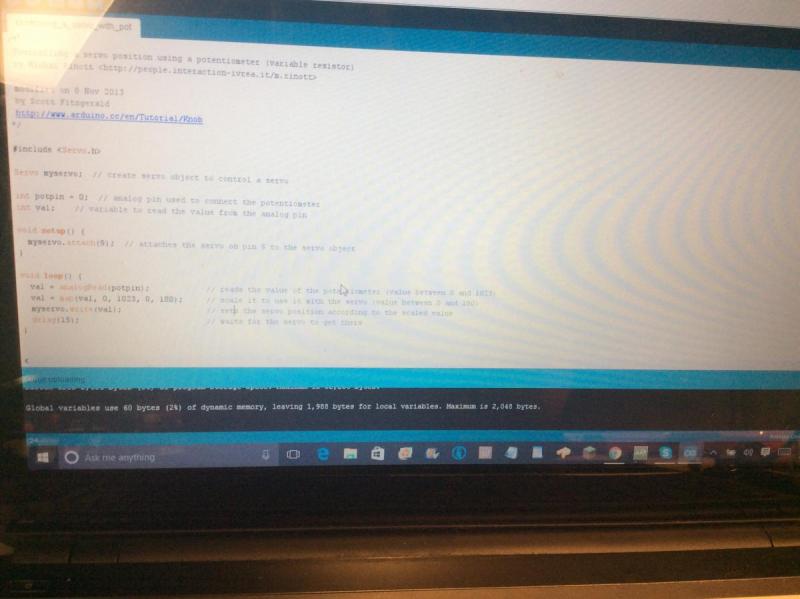

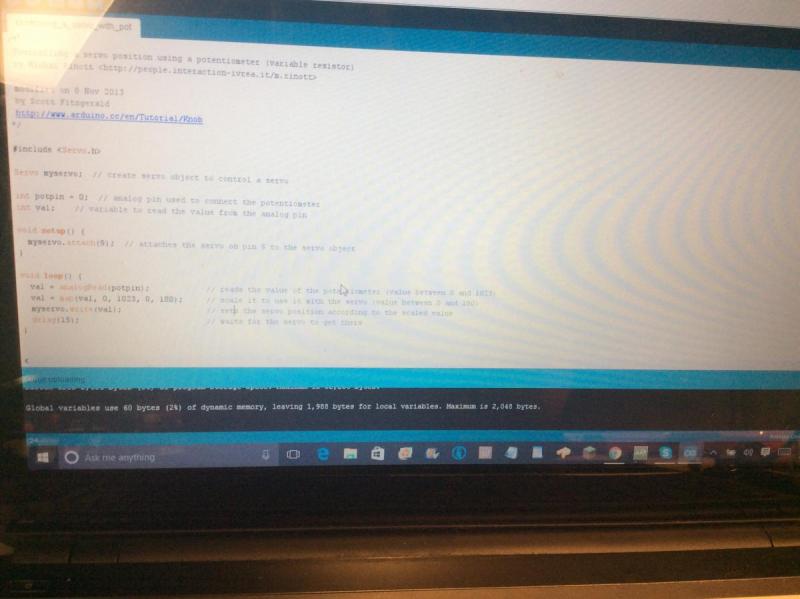

The code, just converting the potentiometer value into a PWM signal

A picture of the homemade flywheel cage installation

Close up of the motor mount I made from aluminum sheet

Last picture before I closed it