Posted 28 May 2015 - 10:51 PM

For the record, you don't want lighter flywheels, they don't spin faster or anything. Heavier flywheels retain more rotational inertia and are better for repeated firing than a lighter wheel. A light wheel will spool up to full speed more quickly (possibly an unnoticeably small amount, assuming you've spent as much on a motor system as you have on these flywheels), but will lose more energy with each shot.

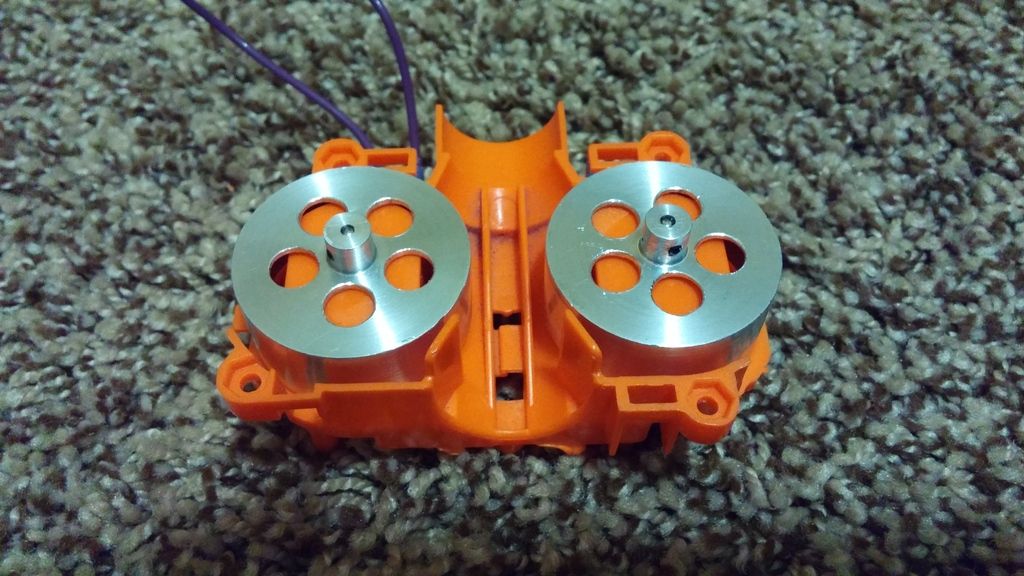

That said, it's possible that with aluminum wheels conventional wisdom for plastic wheels may not apply. It's likely that these are already more than heavy enough to not be affected by a stream of darts flying through. Either way, I wouldn't drill holes in your nice, new, one-of-a-kind flywheels unless your motors aren't up to snuff, even then I'd suggest upgrading the motors instead.