Sorry I'm resurrecting this, but I have $.02 to add...

I don't think this argument between belt vs flywheel is as cut and dry as it may seem after reading this thread. I think some arguments are not adhering to the laws of science, and some are just not focusing their scientific eye on the right spot. So I'll start off with our working equation (how a nerf dart accelerates using flywheels/belts... any friction energy transfer method really):

Work on the dart ~ Ffriction * distance ~ u*N*A*d

u = coefficient of friction (I think 99.9% dynamic, however I talk about static below)

N = normal force (ie how hard you squeeze the dart)

A = surface contact area between the conveyor (flywheel edge, belt, whatever) and projectile

d = distance over which the frictional force is applied (can be very large for a belt)

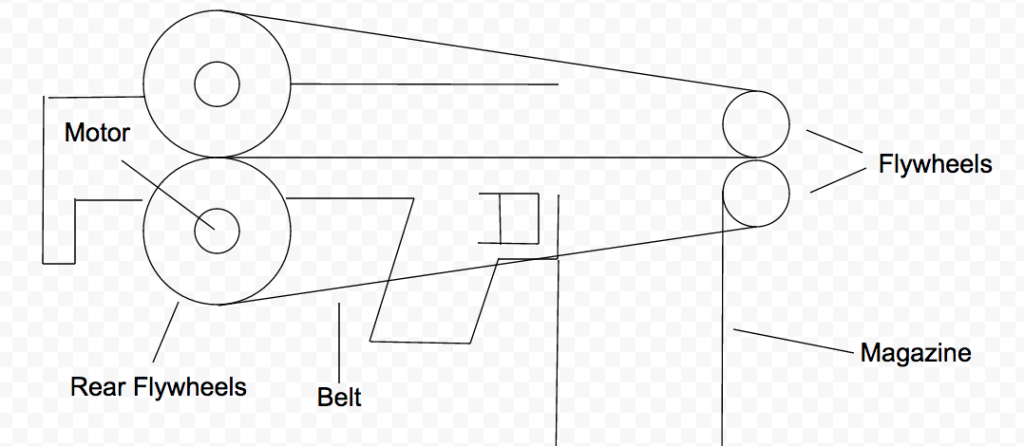

... a very simplified version, but it is enough to make my point about flywheel velocity and size. Flywheel size and RPM aren't even part of this equation, or at least they have very little to do with the dynamic friction available to accelerate our dart. A bigger flywheel may increase A a little bit, you can squeeze the dart more for a bigger N, and use rubber coated ribs to maximize u... but I think a belt will win this battle more often than not. With belts, the friction occurs over a much longer distance, and is applied over a significantly larger area. The distance force is applied in a belt is easy to design, and relatively unlimited compared to flywheels (you can only make the flywheel so big...much easier to play with the distance of the front/rear pulleys on a belt). Of course with a belt, the same leverage over N can be had by squeezing the dart, and coatings can modify u... so those variables don't really enter this argument.

With so much extra leverage over d and A, belts already seem very interesting to me. Then when I think about controlling the belt in a way that allows the static friction to come to play, available force could go way up! That might be doable with a clutch/flywheel accelerated belt, hehe! Yeah you could also use a secondary flywheel and clutch to similarly accelerate a flywheel drive, but with the flywheel drives tiny d (and huge inertia... we won't get into that here), slipping is pretty much the best way to go. The big d of a belt means there may be enough time to maintain a static coefficient (inertia? shoot, those are some super slick lightweight parts in modern RC road race cars that would certainly spool up easier than a big ole flywheel). This would be so cool to see IMHO!

Also, at first glance I think an experimental belt drive may be doable without access to a mill & lathe. I know in the RC car hobby there are a lot of examples of belts running stable at very high speeds, and of course gearbox/motor setups that could be adapted somewhat easily in a typical Nerf hacker's garage. I haven't ran the numbers nor do I have equipment to experiment with, but I'm guessing if the dart emerges anwhere near an RC car's belt velocity, it would be very impressive. I think (due to radial vibrations), a similarly performing belt system could be much quieter than flywheel. Battery life would of course be reduced vs flywheel, but I think something like 20min trigger on time should be easy to do (should be enough, right?... extra lipos in the bag?). Yeah fast RC cars only last 10min, but they're also putting out a c**p ton more work. Spitting foam those setups might last hours. Anyhow, I just don't see battery life as a major design consideration here, but I'm not a veteran nerf warrior. I'm sure there are good arguments to have long battery life in the field. Please share them with us.

Anyhow, that's probably more TLDR than $.02, but I wanted to give my support to those interested in developing a belt nerf drive. It has favorable design trades that IMHO are worth looking in to. I'm fairly confident my arguments are well supported by physics, however I'm no nerf engineering genius (just an old Wolverine BSAE who loves to tinker with everything). Please share your arguments on the belt vs flywheel subject... maybe we'll end up with something to show at the end of it all. Maybe it'll fail, but I think it's got enough merit to deserve a go.

Kevin

Edited by truglodite, 02 May 2017 - 12:38 PM.

[/URL][/img]

[/URL][/img]