Preface

A friend of mine mentioned she would shoot a bow and arrow before going to a shooting range. Naturally this got me thinking of the AAbow, and I decided to make one. I tried making the one found on Mostly Harmless Arms' site, and ended up with a super leaky bow that did not even fire darts. The creation of this blaster also involved a lot of hammering, and even so did not perform at all. I did not have access to 1/2" Thinwall PVC pipe either, so I changed the design a bit to allow for easier assembly and no hammering, so I could build this at 3AM and not wake up my family. Additionally, this uses a lot of goop. Make this outside so you don't die.

References

Thanks to Mostly Harmless Arms and Kane the Mediocre for the original AAbow designs, without those, this writeup would not have been possible.

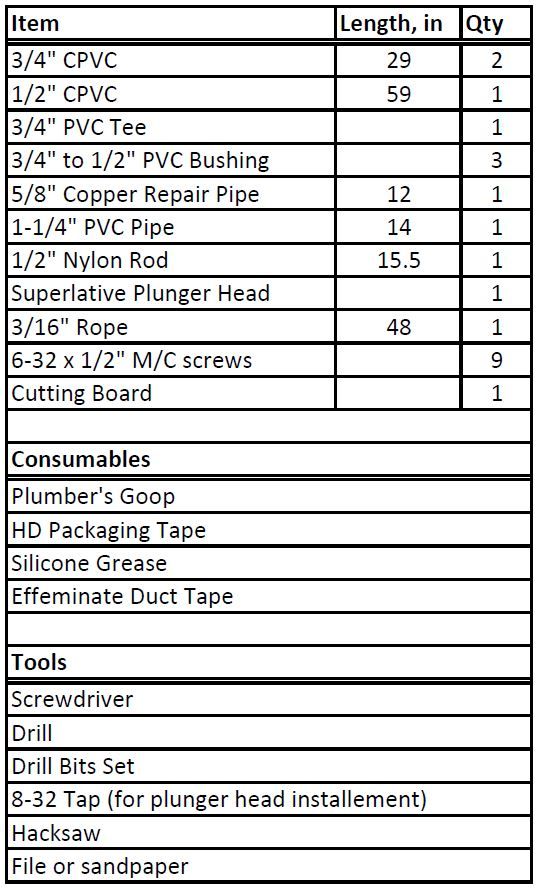

Stuff You'll Need

Instructions

Saw off the inner lip of two of the three 3/4" to 1/2" bushings. These will constitute the bow arms. The untouched bushing will become the bushing that holds your hopper.

Bevel that edge. It will make it easier to side over the tape later.

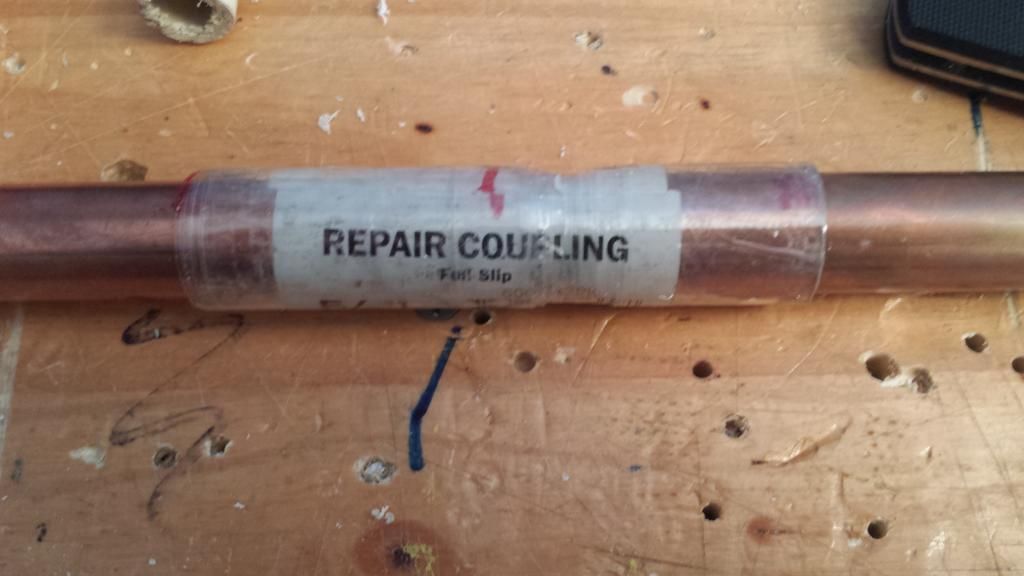

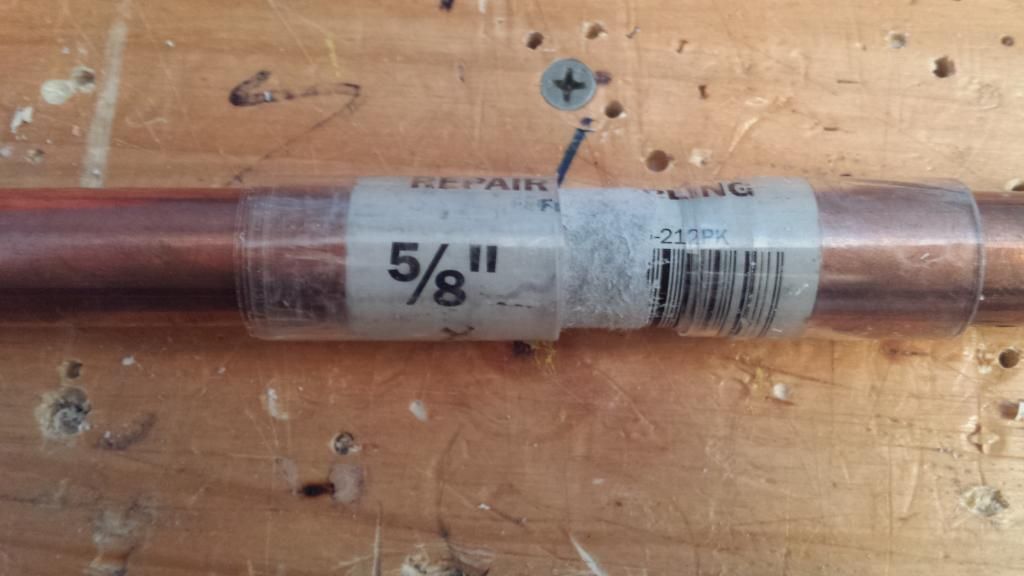

Mark off the center of the copper pipe, and align the center with the middle of the PVC Tee. Mark off the ends of the arms of the PVC Tee against the copper pipe. We'll use these markings later to align everything.

Wrap tape around one side of the copper pipe, aligning the tape with the mark on the side that was just made. Repeat on the other side.

Trim down the tape so that both ends align with the outer sharpie marks...

Trim about an inch or so of the tape from the middle of the copper pipe. This improves airflow later on.

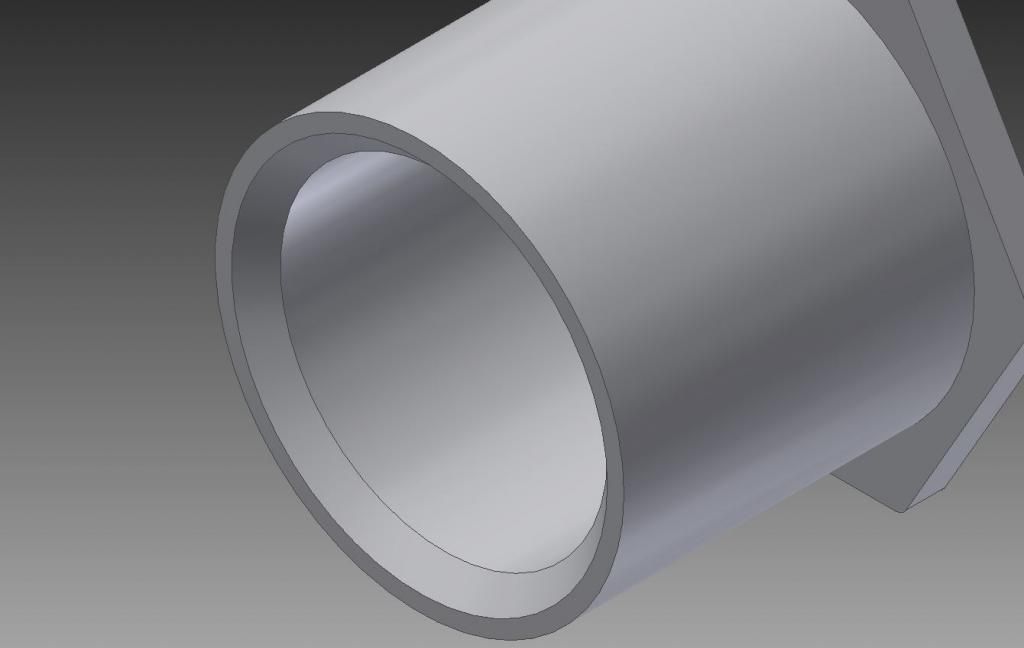

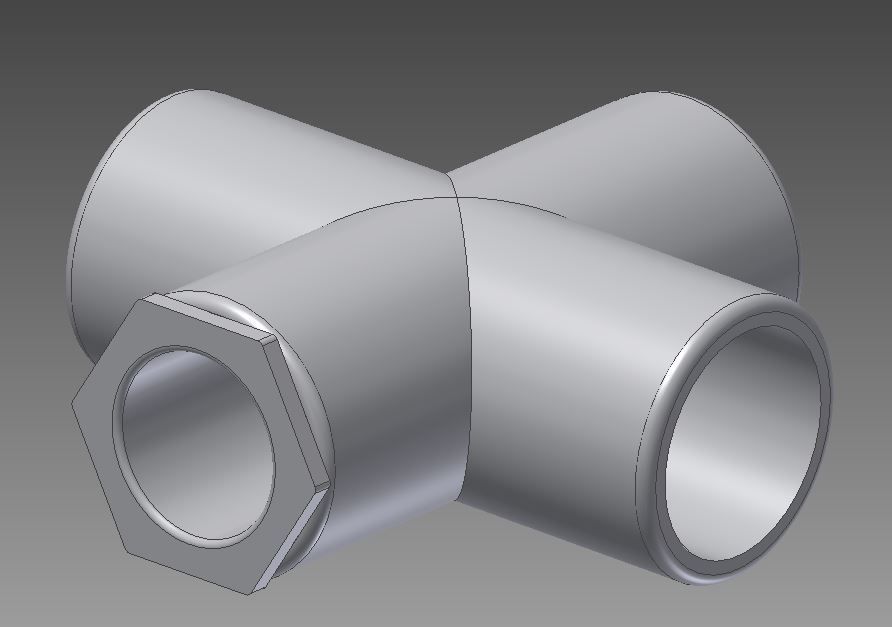

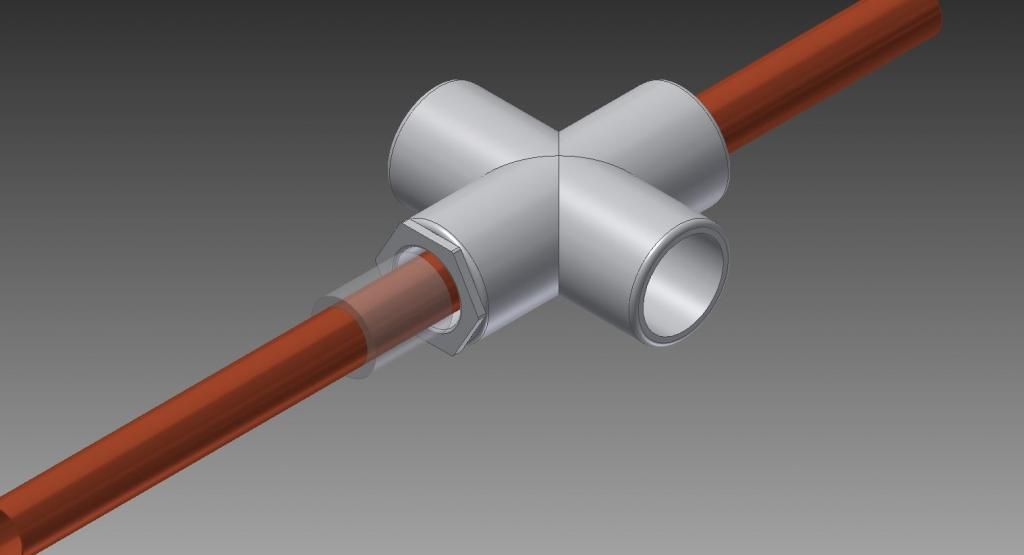

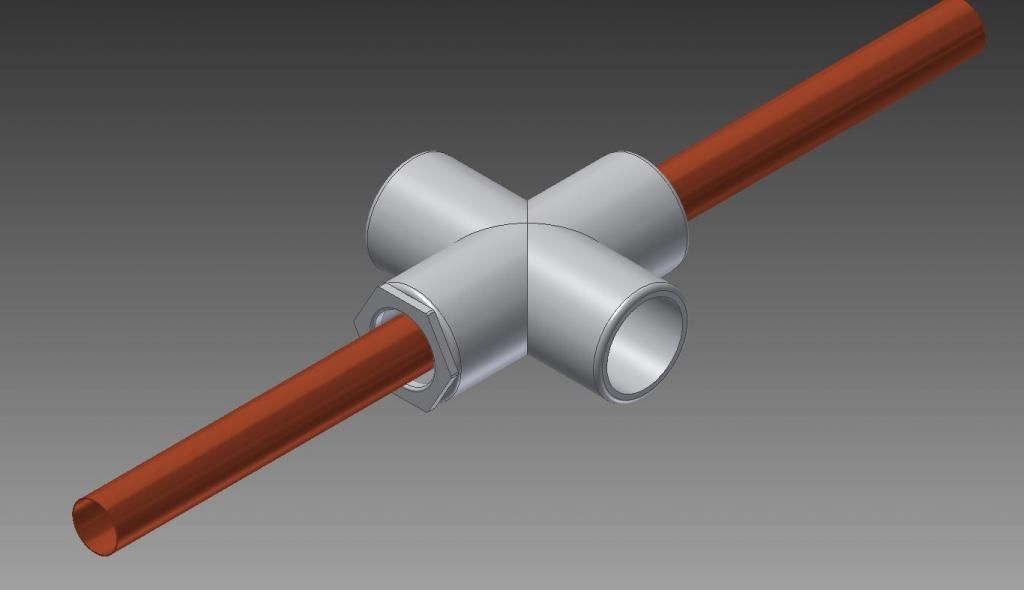

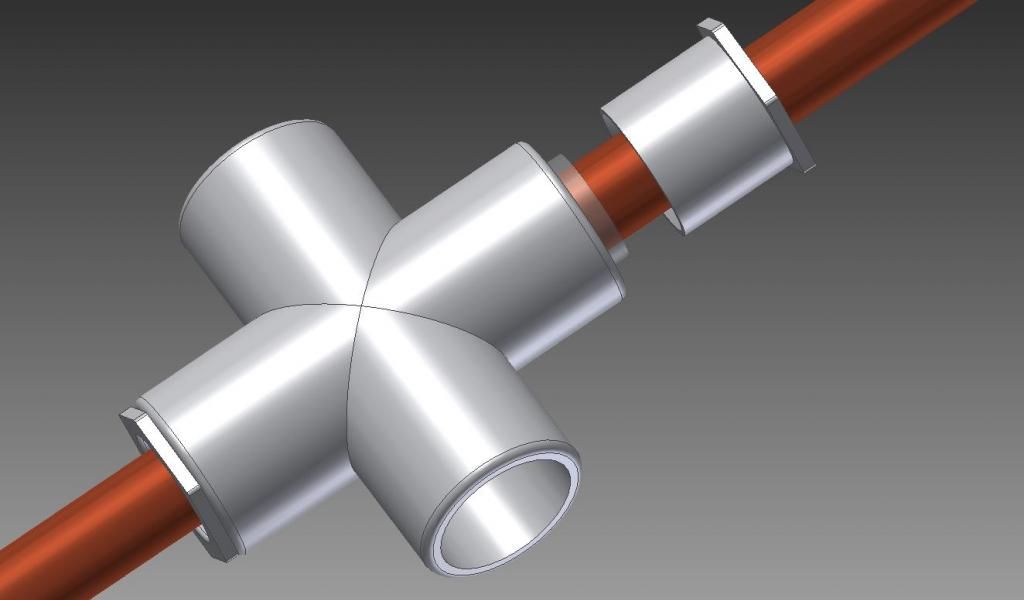

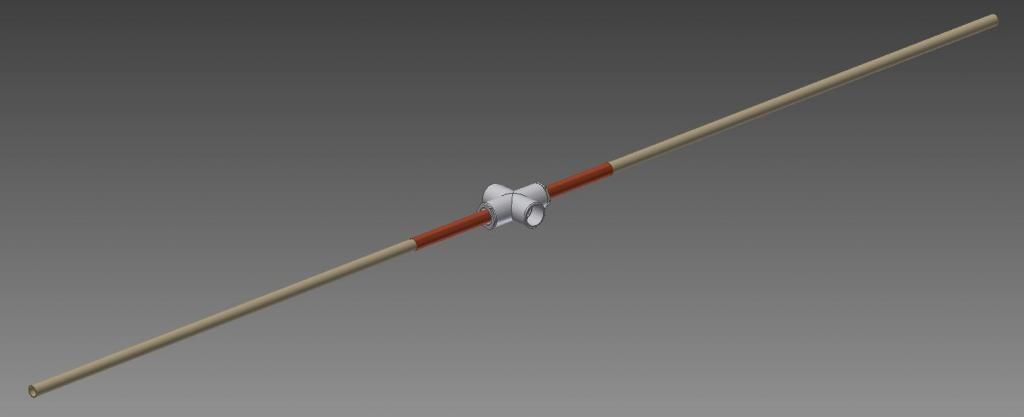

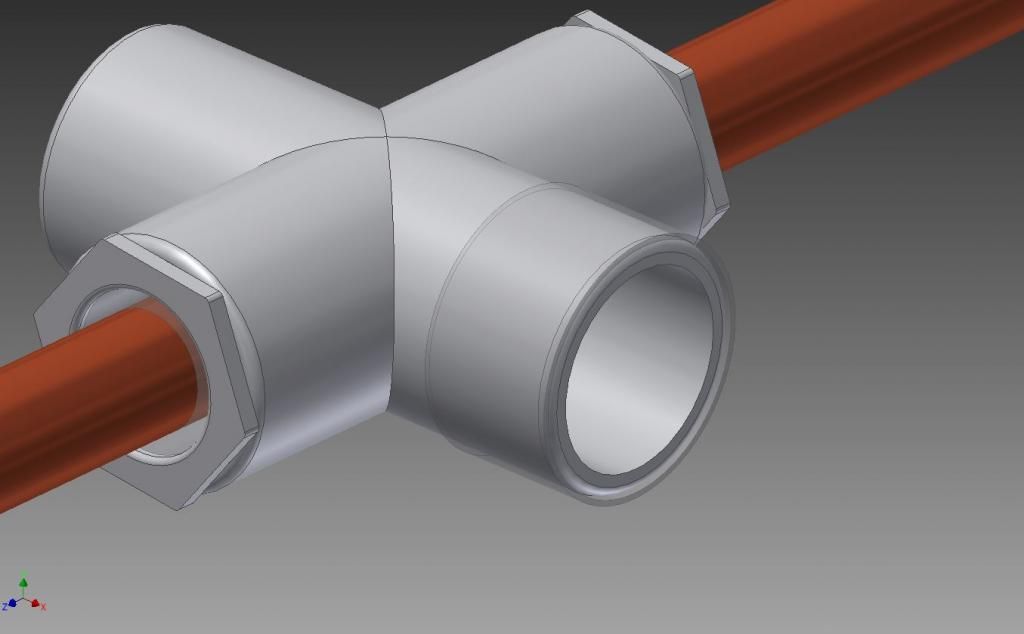

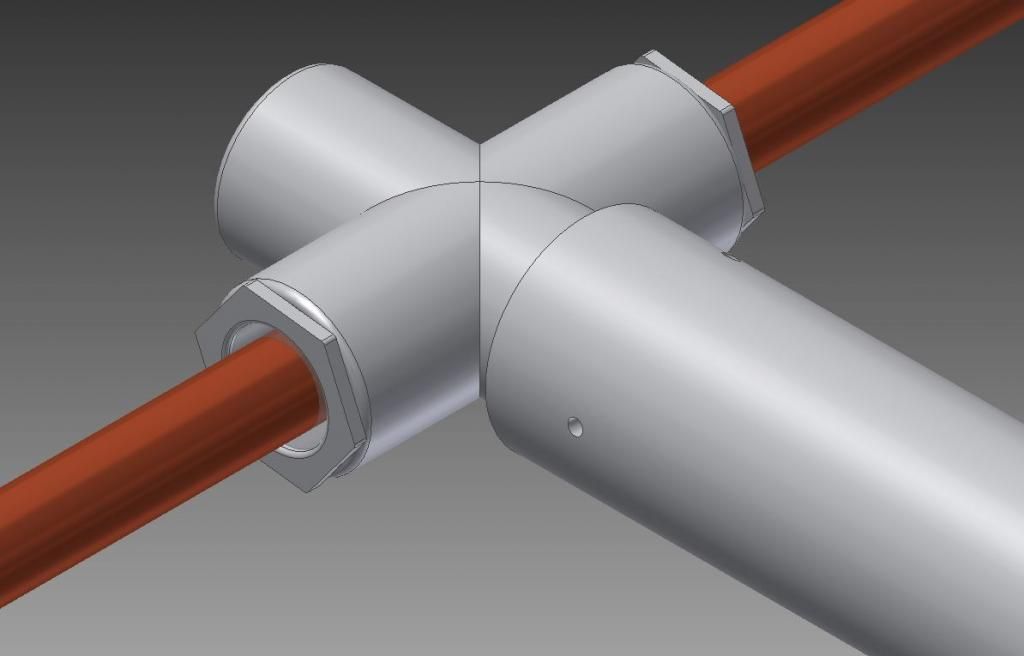

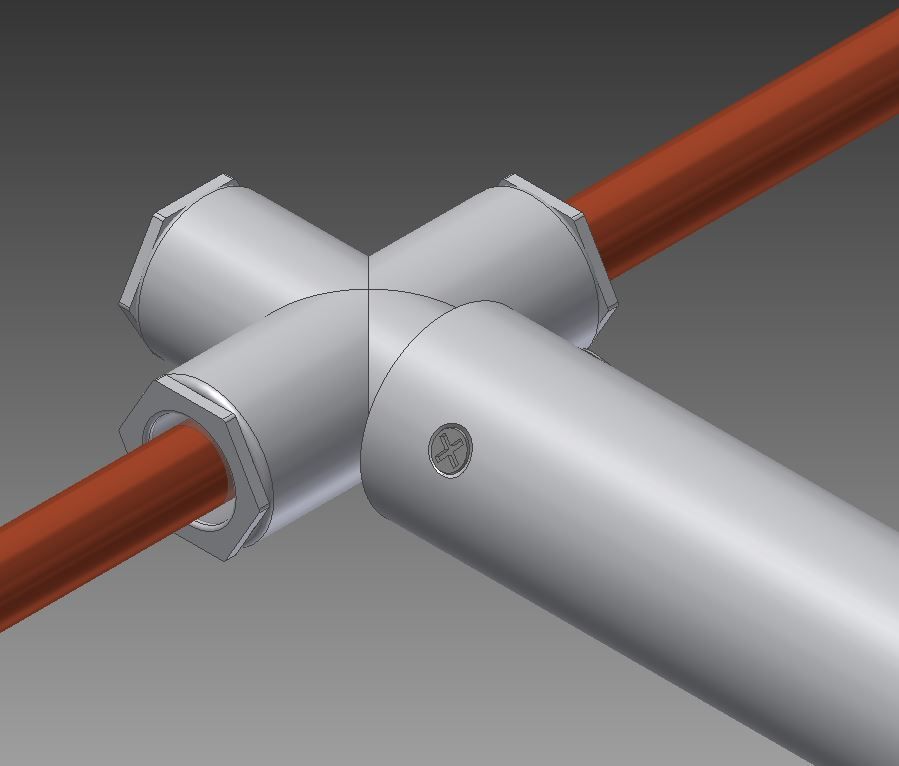

This is the part where my camera decided not to take pictures and we have to resort to CAD drawings instead. Sorry to all the instagrammers here, this will not be artsy. Also, GO OUTSIDE NOW we need some goop.

Apply a thin line of goop around one of the trimmed bushings then insert it into one of the tee openings.

Apply goop on the tape on the copper pipe, then insert the copper pipe into the bushing up to the tape.

Just like that.

Now, add goop around the outside of the bushing as well as the inside. Then insert this bushing onto the other side of the tee. This creates our airtight bow arms.

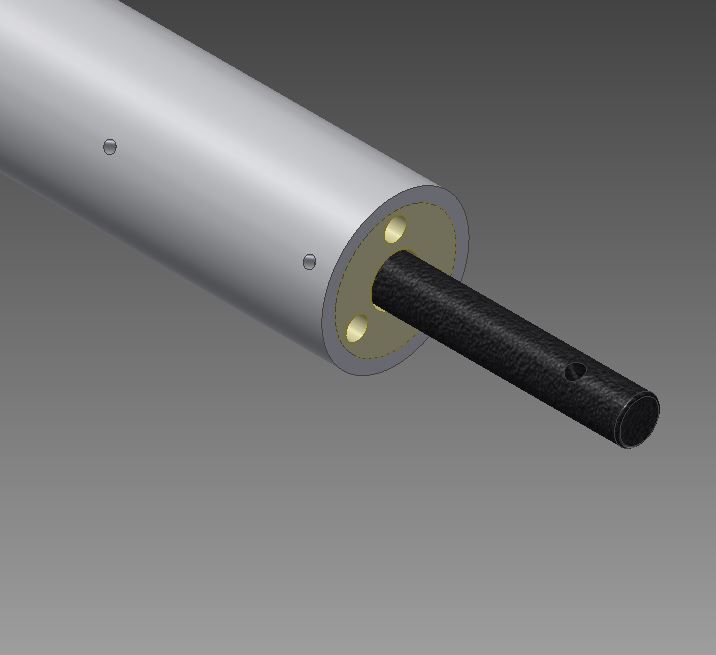

Insert the 1/2" CPVC pipe into the copper, and mark where the pipe is centered. Secure it with a wrap of packaging tape on each side, connecting the copper tube to the CPVC.

Wrap one of the remaining tee arms with packaging tape, until the 1-1/4" PVC plunger tube fits snugly.

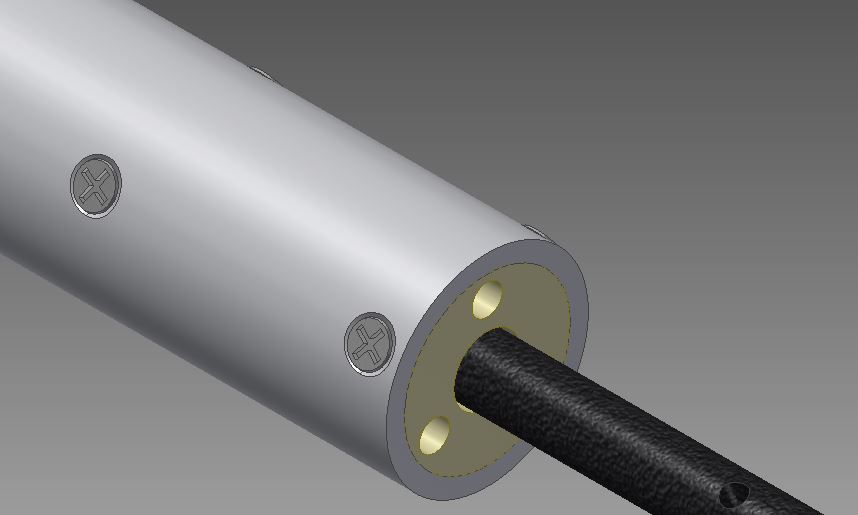

Drill some holes.

Sink some screws. I also placed in the forward bushing (the uncut one) at this point.

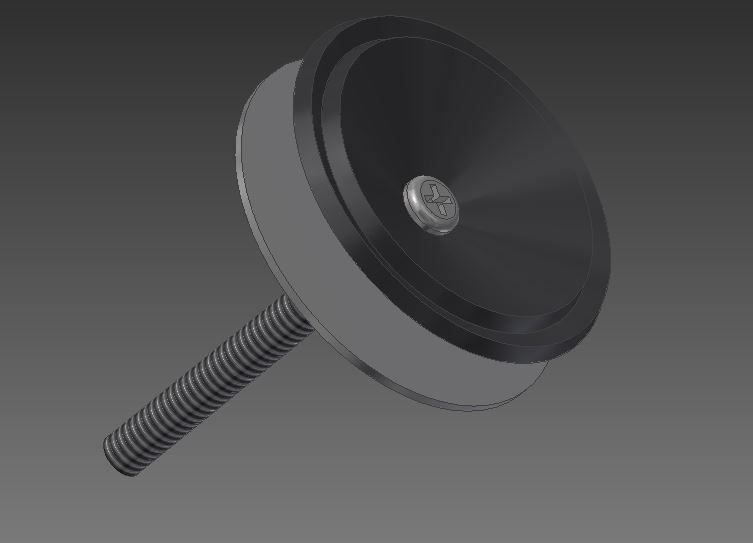

Cut your nylon rod, and drill a 3/16" hole about 3/4" from on end. At the other end, drill a 1 inch deep hole and tap it for an 8-32 M/C screw.

This is a superlative plunger head.

Throw on your plunger head. Add lots of lube on there and insert it into the plunger tube.

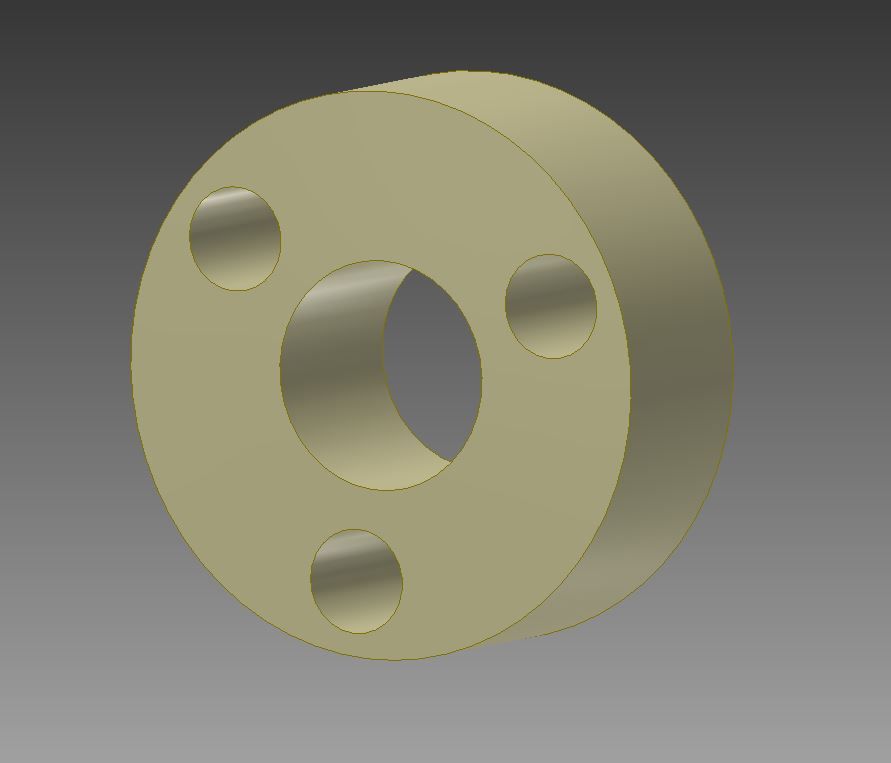

Make two of these from the cutting board. I used the hole saw I used to make rainbows, and then added extra holes to avoid a vacuum forming upon firing.

Throw in the cutting board spacers. Make one about 2.5 inches from the rear face of the plunger tube, and one flush with the rear face. These provide two points of support for the plunger rod to rest against, keeping the plunger rod relatively straight without the use of a supporting bar.

Sink in some screws.

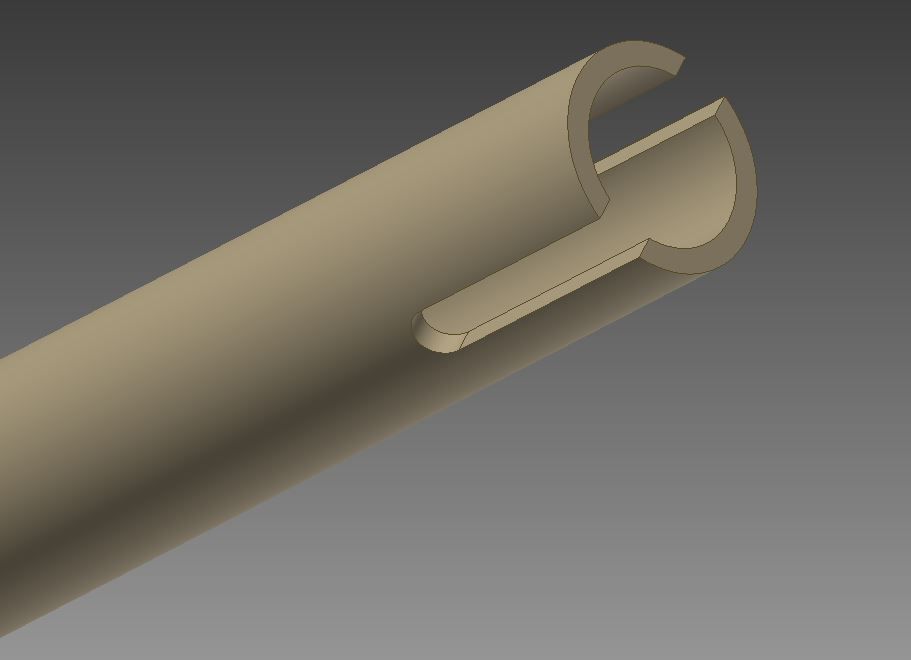

Create a slot at the end of the bow arms 1 inch deep. Start with a 3/16" bit and then use a saw to finish the slots.

If the bow arms aren't on very tight, then use a wrap of packaging tape around the copper to increase the OD of the pipe, allowing for a tighter fit against the bow arms.

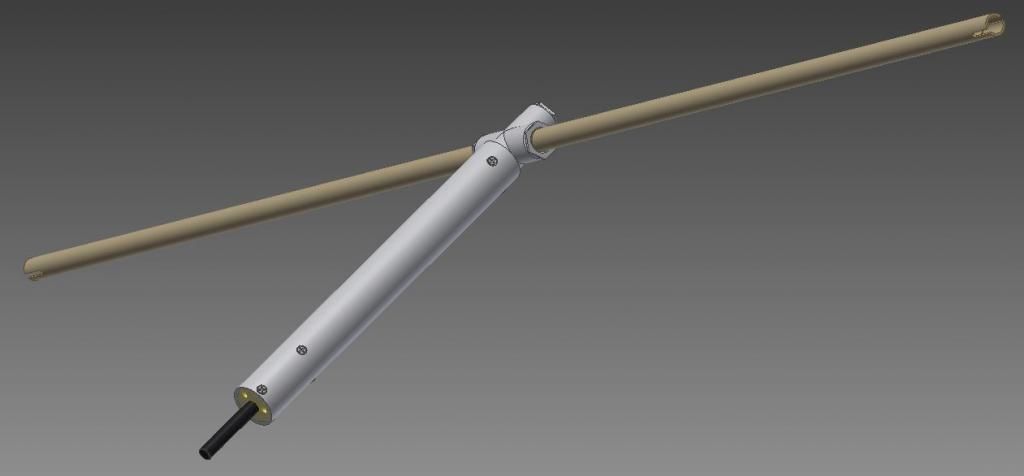

Add the bow arms. Then string the bow with the 3/16" rope.

In the fume hood.

Results

It's pretty good. Use gloves when you fire this thing, your fingers will be hurting real soon after firing this. Don't be a hero, just get some biking gloves. It shoots really hard. The use of the 1/2" CPVC running the entire length of the bow arms serves to increase the potential energy in the bow arms without increasing the draw distance, which is already pretty substantial at ten inches. I'm using a 14" barrel, but I'm probably going to upgrade to 16 or 18 inches. Works very well with a hopper, and has a good, but not perfect, seal. Goop and tape seems to work at providing a perfect or near perfect seal, so I used that to create this AAbow variant. Give It a shot, the only thing you can't get from the hardware store is the Nylon rod, but I really like this.

Do not use this without goggles. If the rope snaps you can bet you're getting slapped hard in the face.

I like it. You'll see it next time you're in the Northeast

Edited by Aeromech, 23 November 2015 - 01:24 AM.