This is a Drev Bullpup with a reverse wye chopper, and one that started the inquisition. I'm using a chopper because I wanted to keep this as compact as possible, but a hopper without the 45 degree coupler would actually work better, because you don't have to change position to load a new dart into the chamber.

This image, posted by Gears was the one that actually inspired the above blaster, a bullpup with a horizontal top feeding magazine. It keeps everything compact and I wanted to give it a shot.

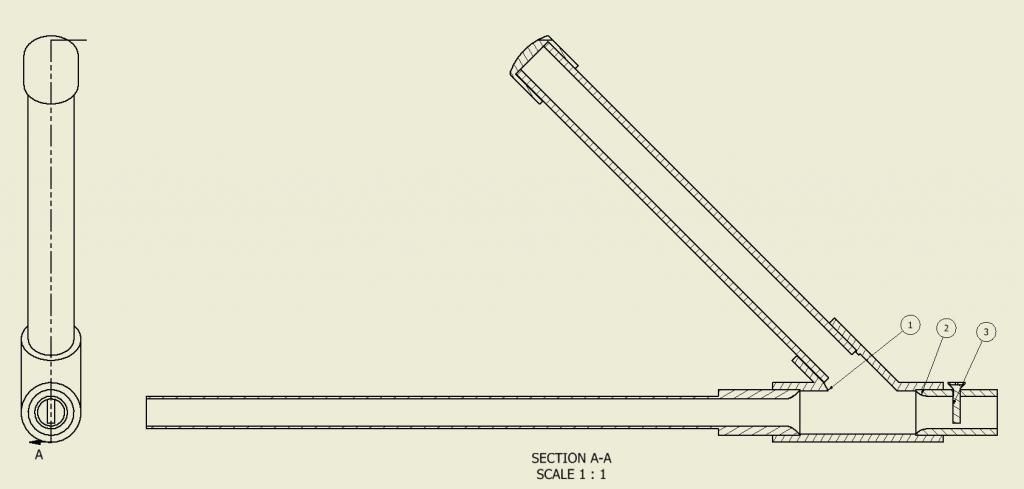

Here's the full assembly. Darts are loaded with the heads facing upwards. When the blaster is primed, the suction from the skirt seal actually pulls the dart backwards into the stub; the screw in the stub prevents the dart from being sucked into the air supply source. The dart is now seated and the head should have fallen away from the clip. The dart is now in line with the barrel. When the blaster is fired, the dart is forced out through the barrel.

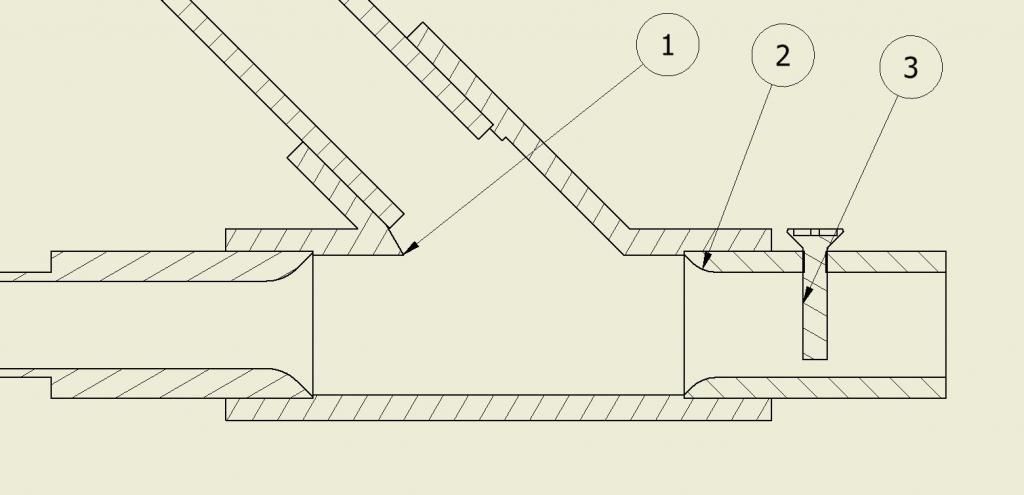

And here's the detail view.

(1) Marks the area that needs to be filed down with a rat tail file, just get it in there and start removing material. It will feel new and strange at first, but you'll learn to enjoy it.

(2) Denotes the part of the stub that must be chamfered smooth. Just like the barrel, a bevel is necessary to allow the darts to feed smoothly backwards into the stub. Just do this like you would do it on the barrel throat.

(3) The screw that prevents the darts from being sucking into the air supply chamber

Notes

This has not been war tested, but it seems to work pretty well. Keep in mind my darts are slightly shorter than the standard, I usually rock about 1-1/8 inch long darts. Don't ask me how I arrived at that figure. If your darts are longer than that, just adjust the distance of the screw from the throat of the stub until you get reliable feeding. This sort of solves a problem that doesn't exist, but I hope it may be useful to some of y'all out there.

She likes showing off.

Edited by Aeromech, 07 January 2015 - 06:16 PM.