For a while now I have been experimenting with the use of 1/2" aluminum u-channel as a means of a catch mechanism for a nerf blaster. After several revisions I have come up with a system that is based on the SNAP catch, but is much more repeatable with the elimination of the clothespin part of the mechanism. I believe that this new design offers a strong reliable system that applies to blasters of all types, while still being machinable from ordinary tools.

Materials

1/2" aluminum u-channel

-can be found at most home depot's/lowes, the first one needs 1 1/2', but

less than 3" for each subsequent blaster (the extra is for tool use)

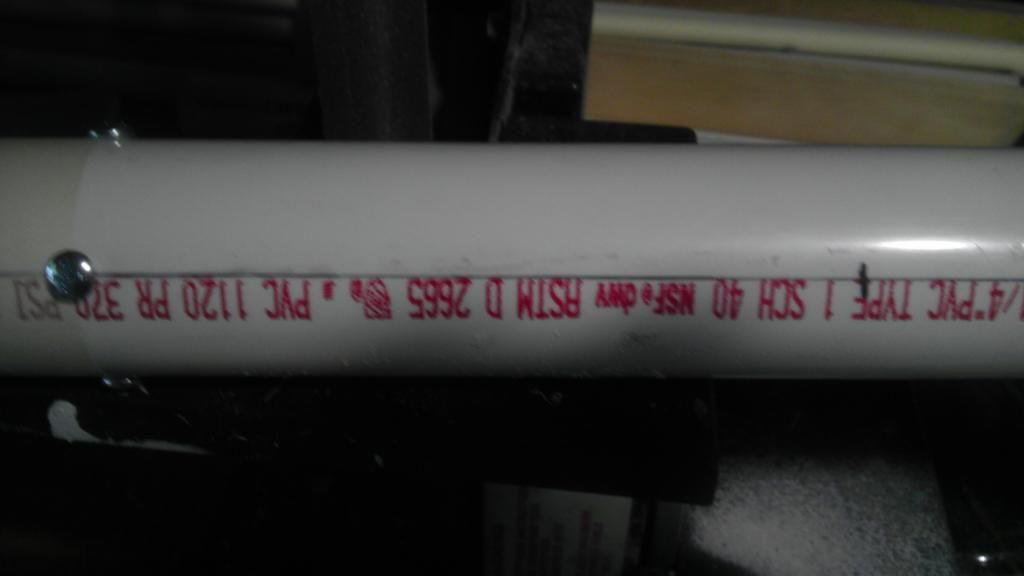

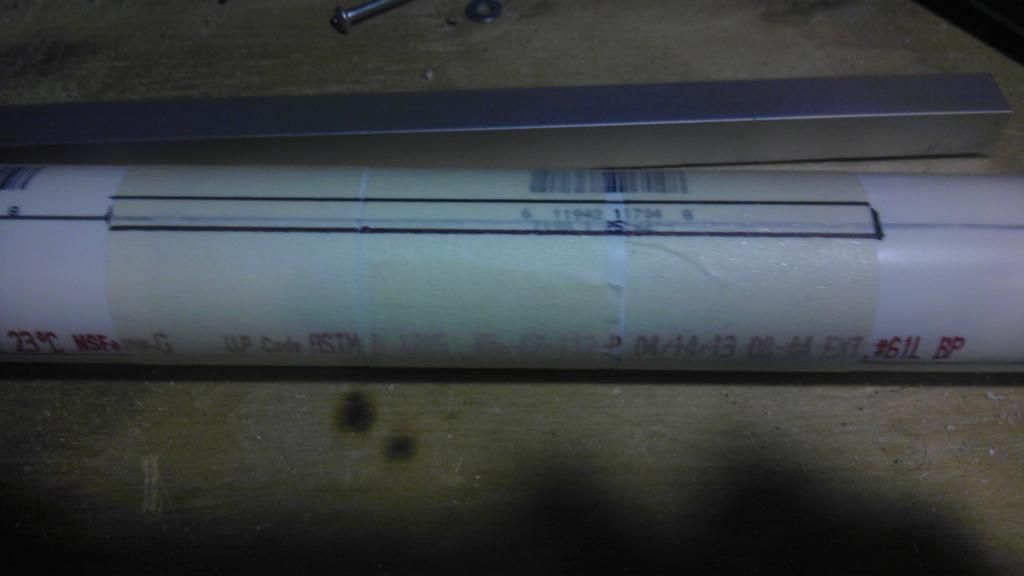

2' of 1 1/4" PVC pipe

-Yes, the 2' sections from home depot are perfect

1"x2" lumber

-you only need about 9", but a very fine handle material

an assortment of machine screws

-I prefer 8-32, but 6-32 are popular around these parts, you will need one 6-32 machine screw, you will need a tap that matches, so plan ahead

a cutting board

-Dont use your mom's, she will be very upset with you

-a good thick one from wal-mart, about $7.50, or use polycarbonate (preferred)

1/2" nylon rod

-you can get this from McMaster, if not you can use a wooden dowel from a big box store, anything 1/2", round, and reasonably strong should work

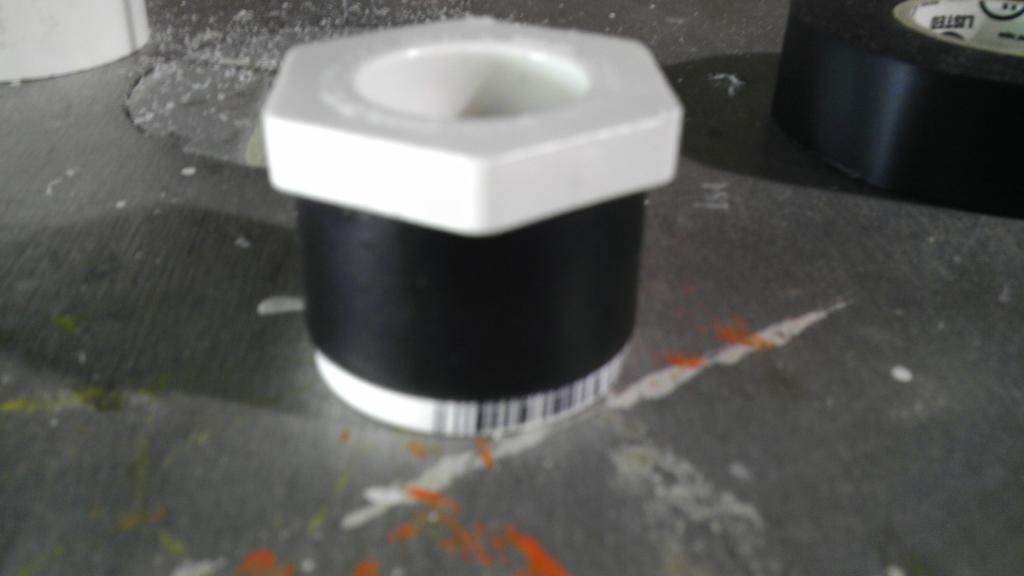

1" to 1/2" PVC reducer

-only if you want to fire darts

1 1/4" PVC coupler

-trigger mechanism mount

1 1/4" PVC tee

-Used for shoulder rest (I didn't becasue I wanted to be fancy, don't let that stop you)

1 1/2" fender washer x2

Your standard homemade blaster rubber washer

-McMaster 9562K46 you may want more than 1, just in case, or for your second one

[k26] spring

-This is nerfhaven, they get used for everything McMaster 9637K26, but I will show steps to use any reasonable sized spring

Tools

Dremel

Hand drill

Coping saw

Sandpaper

Tap for your preferred screw

Round micro file (The cheap wal-mart file set is worth its cost)

Pliers, screwdrivers, etc...

That said, power tools will make your life easier and the process faster, go on craigslist, a decent drill press, a scroll and/or band saw, and especially a belt/disk sander are easy to find for pretty cheap, I got all three of mine for $100.

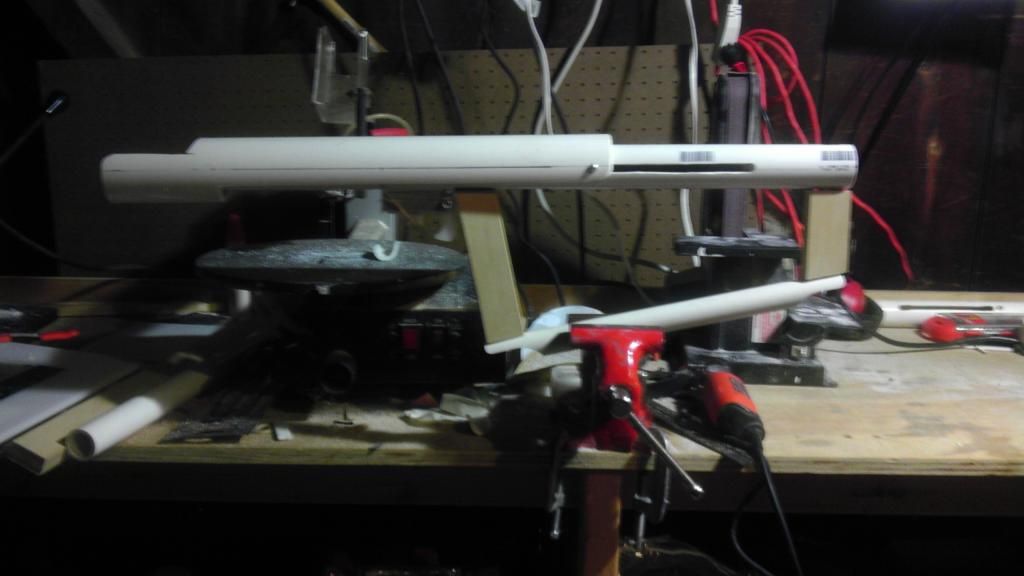

The trigger mechanism

I'm bad at measuring things, so to get most of the sizes right I derive them from measurements, you may notice this in the write-up. Adam Savage of mythbusters fame talks about saving time by knowing when you do and don't need to be precise, so when a sharpie is a valid method of marking cuts, don't be afraid of eyeballing stuff, it is so much easier.

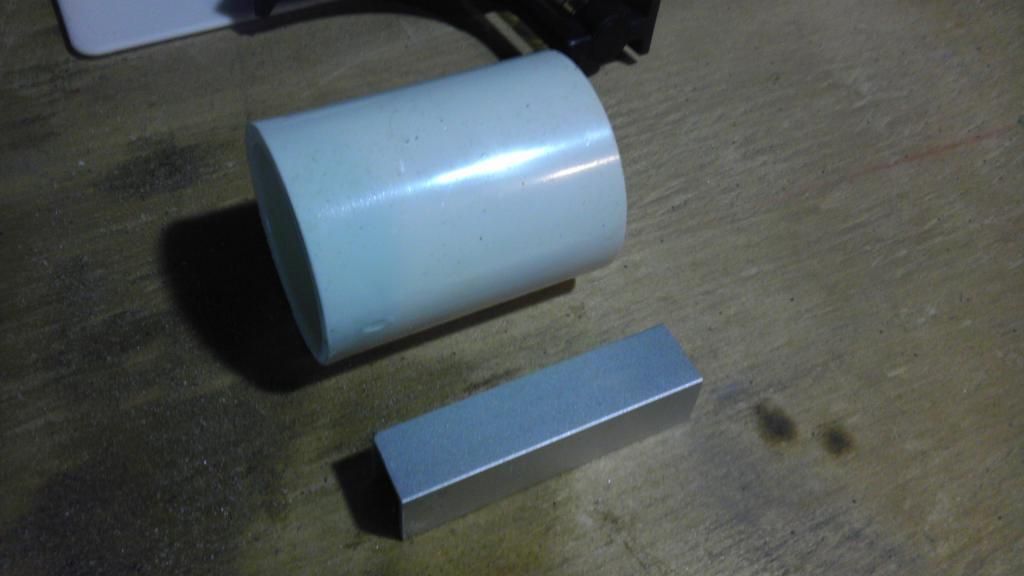

Start off with cutting a section of aluminum channel to the length of the coupler.

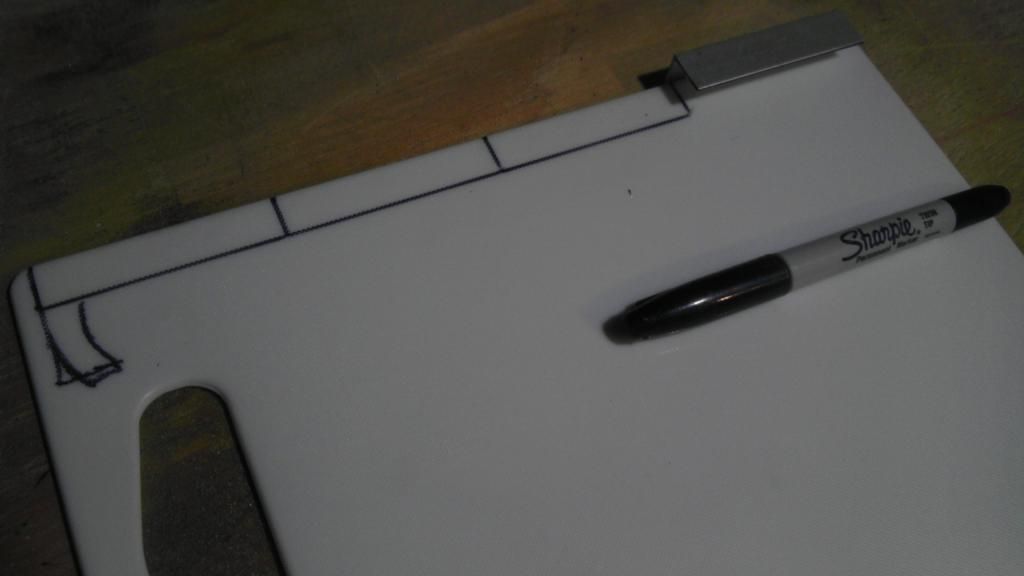

Then, insert your cutting board or polycarbonate into the slot of the u channel, and trace around the edge. Then doodle a trigger onto one end. Don't worry about the other rectangles in the picture, that was only for a test.

Now you need to drill a hole in the u channel, this will act as the pivot for the trigger. You will want to make it halfway between the gap and the back plate, and about the same distance from one side. The pictures will help guide you. As you can see, mine is a little lopsided, it still works fine. Tap it for your screw size.

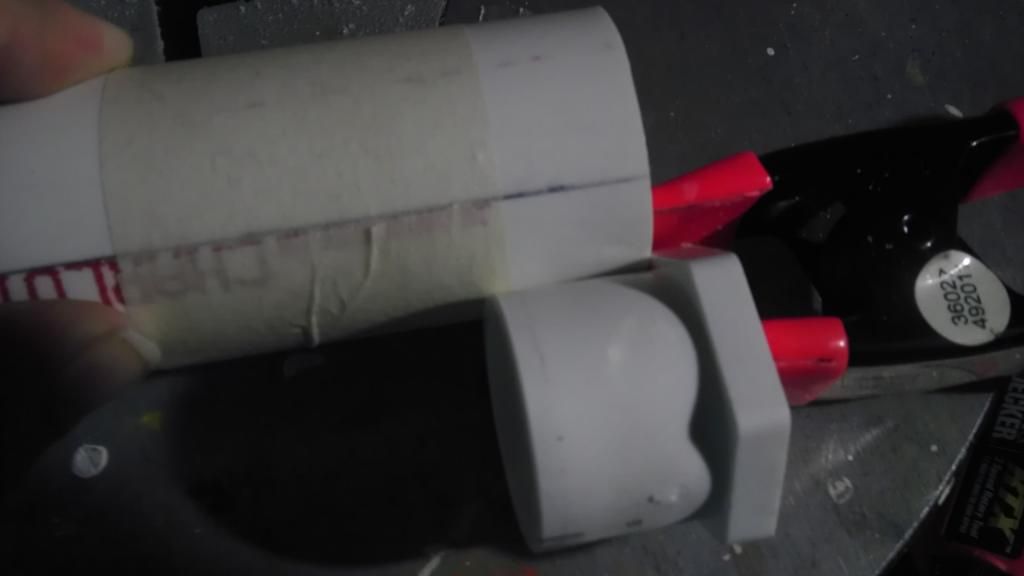

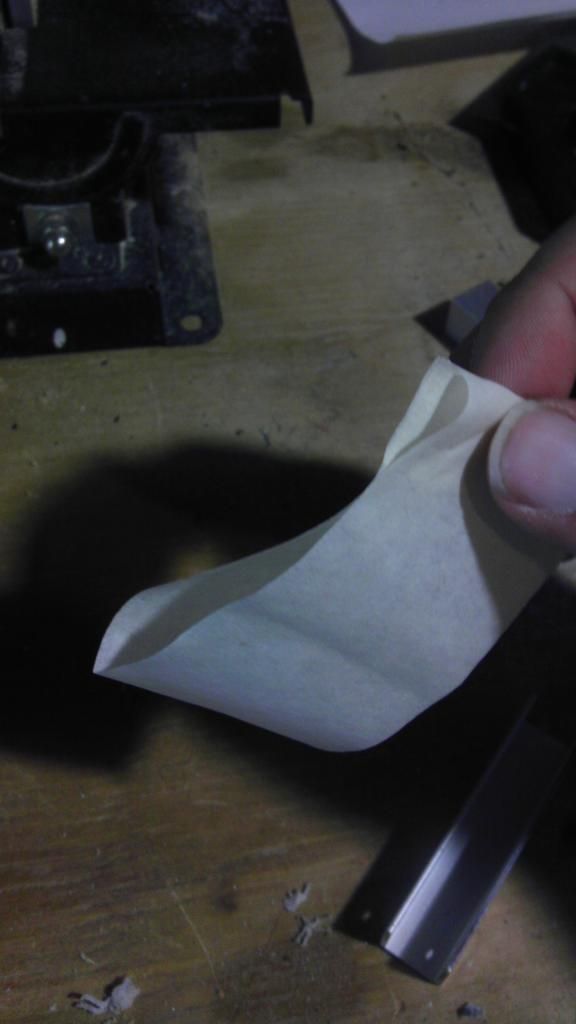

Next, we will use one of my favorite tricks, and quarter our coupler. Start by covering the coupler with one wrap of masking tape. WITH ALL THE MASKING TAPE TRICKS THE ENDS NEED TO BE IN LINE WITH EACH OTHER. That is, the tape forms a perfect cylinder around the piece.

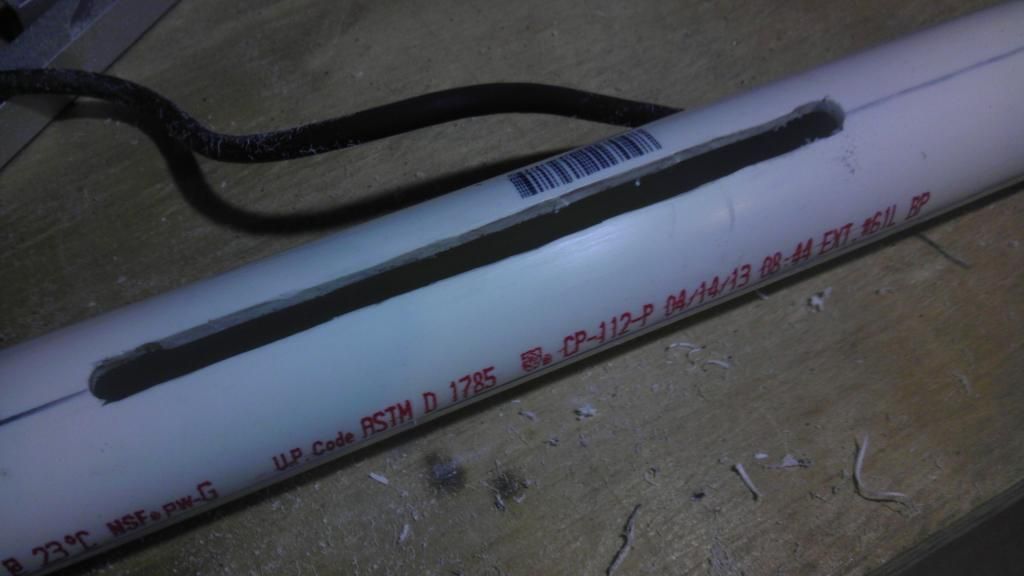

Then, cut off a 1' piece of aluminum u channel, this is now your favorite tool. Caress it if you like. Hold up the sloted end of the u channel to the coupler, with one "leg" over the seam of the tape. Because of 3 dimensional trigonometry, it turns out that where the u channel meets the coupler (or pipe) is a perfect line down the side of the cylinder. This is why it is a nerfers favorite tool.

Use a knife to cut through the seam of the tape, remove the excess.

The tape, when removed from the coupler will have a length exactly equal to the diameter of the coupler. So we will remove the tape, and fold it in half non-sticky side to not-sticky side to create a seam.

Then, use the seam to fold the sticky sides together, the tape is now equal to exactly half of the diameter of the piece.

Now, fold the tape in half again. This can now be used to quarter the coupler.

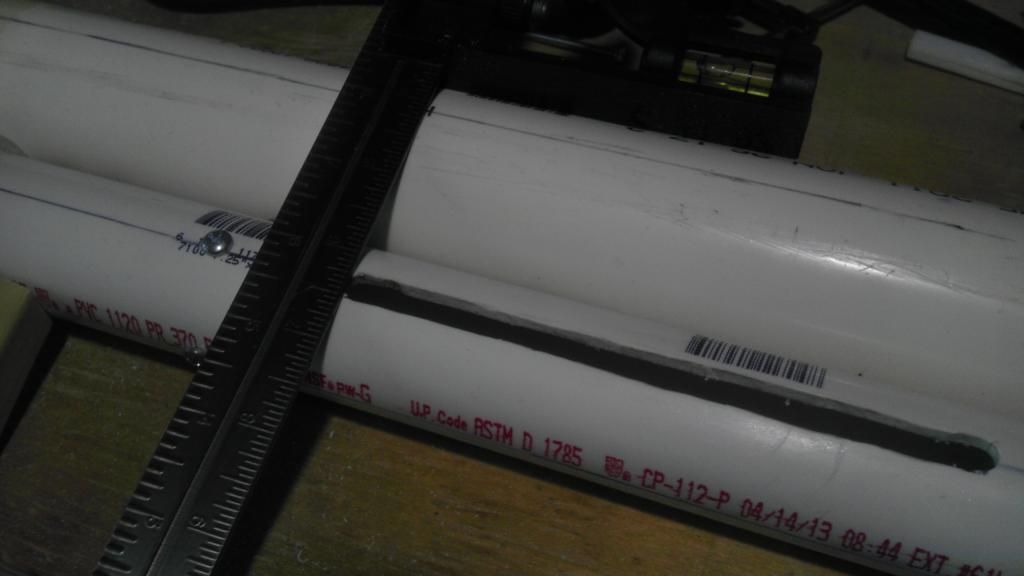

To quarter the coupler, first put a line on the coupler using the u channel.

Then use the folded tape to mark each quarter along the outside of the coupler. Where the fourth the mark would go, you should line up with the line you made first, this is how you know the marks you made are exactly on quarter around the circumference of the coupler.

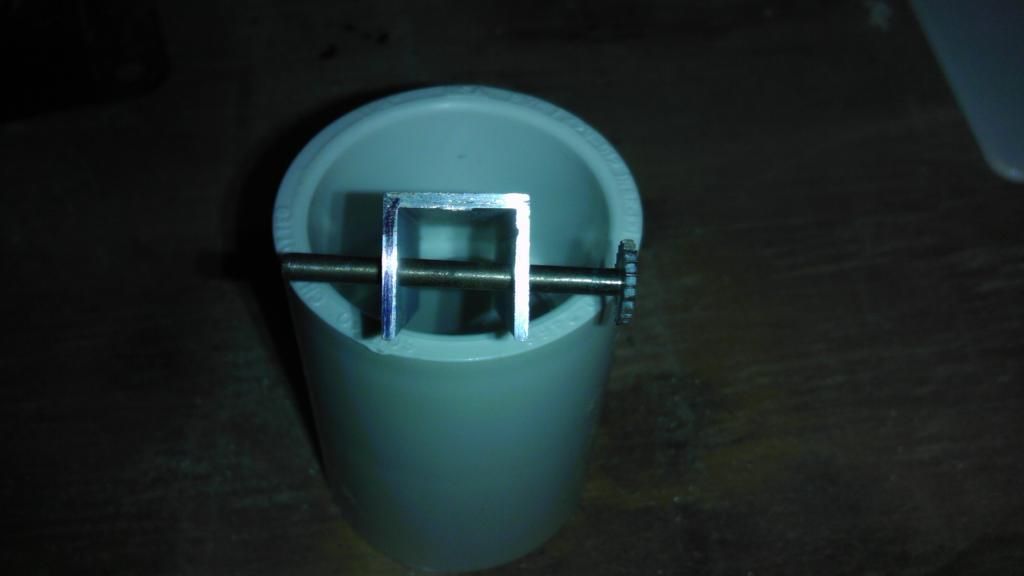

Now that we have the coupler quartered, we can attach the u channel.

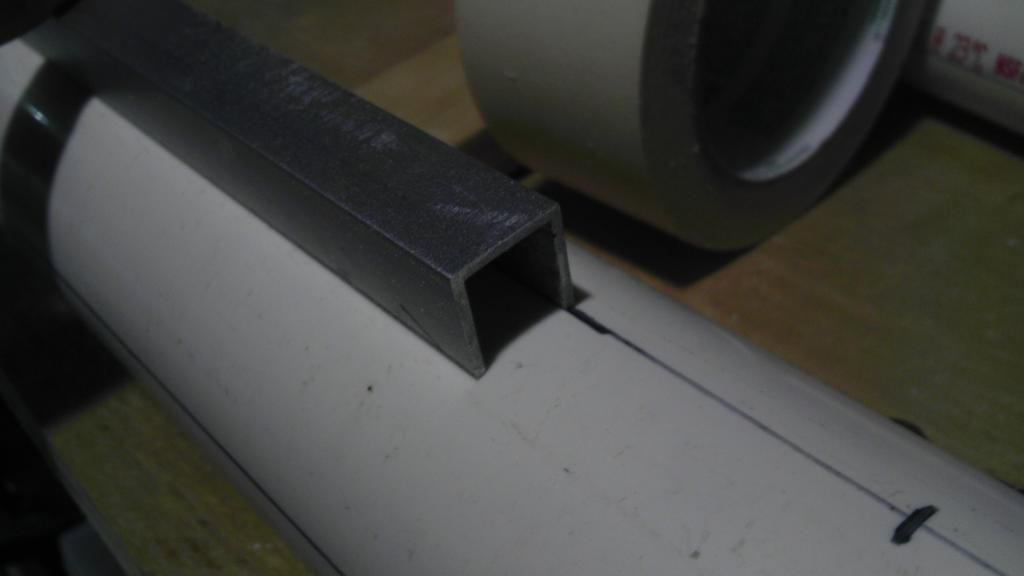

Try to line it up with one of the lines, it doesn't need to be perfect, just somewhat straight. Reinforce it with putty, and any other super adhesives you may have.

Then, you are going to want to remove this lip from inside of the coupler, just enough to slide relatively easily on the 1 1/4" PVC pipe.

Now we are going to work on the trigger. Take the piece you traced out before, and cut it out. Hold it into the u channel, and mark where the pivot hole is, drill out the hole.

Use a small round file to open up the hole so a screw can slide through it easily.

Now on the part of the trigger that meets up with the top of the u channel, make a line down the center, and drill straight down about 2 inched away from the actual trigger.

Temporarily mount the trigger in the u channel, make sure it is centered, then drill a hole through the u channel and coupler.

Since this hole will house the catch pin, we will need to clear some space for the pin to move freely. Do this with a small round file.

Now we will make the band rest for the catch pin. Just take a small piece of scrap plastic, and cut a small v out of a rectangle, refer to the picture for help. Be sure to round off all of the edges, you want to create a minimal amount of stress on the rubber band, shearing it will break the mechanism.

Now drill and tap a hole at the bottom of the v. Use a 6-32 here, as it will easily fit into the side of a 1/4" piece of material, with enough space for you to fudge it up a little bit.

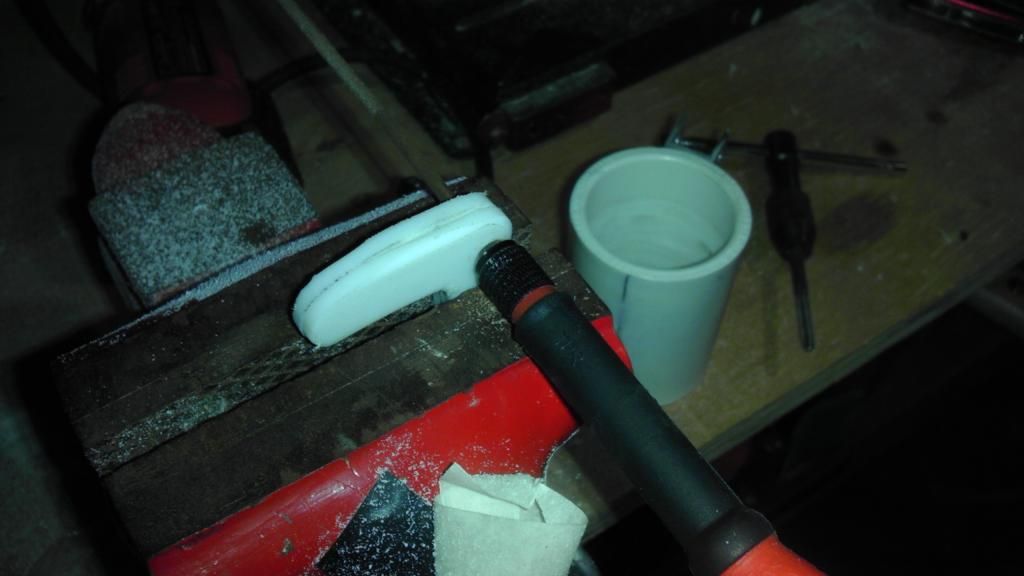

Now we will make the catch pin. To do this take a 6-32 machine screw, about 2.5" - 3" long, put a single nut on it. Using a pair of pliers to hold the nut, use a screwdriver to spin the screw while holding it against some sort of grinder, I used my belt sander. CAUTION, IT WILL GET VERY HOT. Using the screwdriver to spin it in the nut helps to create a more round profile on the screw.

When finished, you should not be able to see any threads, and the head should be rounded off to prevent wear.

After it cools, remove the nut, and screw it into the band rest.

Now you can place the catch assembly into the bottom hole of the trigger. Then put on a rubber band to act as a trigger spring. This will complete the trigger mechanism.

I will update this thread as soon as I can (tomorrow?) with the rest of the build. Until then I leave you with this trigger mechanism to think about. A little bit more work than a SNAP, but with notable upsides. It is fairly easy to make, and super cheap to build.

Please wait for a few minutes while I reserve Space for the rest of the posts.

Edited by Aeromech, 23 November 2015 - 02:49 AM.