#1

Posted 29 October 2013 - 11:33 AM

I just made my first homemade spring-loaded gun (my second homemade). It's a Rainbow. First I'd just like to say thanks to this community for inspiring and helping me with all the great tutorials.

Now on to the issue. The seal is not perfect. When I hold my hand over the front of the gun and fire, air clearly is leaking back out of the holes in the back of the gun, so it's slipping past the plunger when compressed. It's not terrible, it does compress air and it doesn't dry fire when my hand is over it, but I want to make the seal perfect so that the plunger stops dead like I have seen in so many of your videos.

I'm open to any suggestions or descriptions of any other things people have done that has worked. I am hoping that this thread can become a discussion of all the ways to make a really good seal and debug an imperfect one. Mostly, though, I'm hoping to figure out how to fix my own.

My current setup is using a 3D printed plunger head along with a skirt seal (aka shaft seal) from McMaster-Carr and a fender washer to hold the seal on the front. Then I used plenty of silicon grease to lube it up. I put the plunger head up on Thingiverse incase anyone wants to duplicate my design. I'll be updating it based on feedback from this thread.

Plunger head: http://www.thingiver...om/thing:173486

Shaft Seal: http://www.mcmaster....9562k46/=p5bvgg

Fender washer and silicon grease from the hardware store.

I suspect that in order to improve my seal, I would need to increase the diameter of the cylinder that the seal wraps around. This would cause the seal to stretch to fit and press against the inside to the PVC a little harder.

For those of you using the same McMaster-Carr stretch-to-fit shaft seal, what is the exact diameter of the piece your seal's inner diameter is fit around? Mine is 0.894 inches, at the moment. McMaster-Carr suggests that this is for a shaft with diameter 0.95"-1.07". In the Rainbow-Pump writeup that I followed for this design, he used polyester tube that is 7/8" in diameter. This is 0.875. Unless polyester 7/8" tube is actually bigger than 7/8". I am not sure if his seal is much better than mine though but I suspect it is.

Anyone have any tips? Should I just keep incrementing by 100th's of an and print this plunger head again? Can anyone give me the outer diameter of your plunger heads for use with a skirt seal? Is is possible that using a polycarbonate plunger tube is better because the insides are precisely measured and I wouldn't have to worry about deviations in the plunger tube?

Thanks for all the help,

-mike

#2

Posted 29 October 2013 - 12:50 PM

Also, perfect seals aren't really necessary. So long as your darts and barrel are a good match, you'll still get around the same performance. In some blasters it turns out that a perfect seal is actually harmful. In most cases it's about e-peen, rather than actual necessity.

Edited by andtheherois, 29 October 2013 - 12:50 PM.

Photobucket

Winning rounds is rewarding, deal with it. We don't play fucking patty cake over here.

#3

Posted 29 October 2013 - 02:31 PM

Depending on how you printed it, that plunger head may just break. You may just want to replace the whole part with polycarb and do a regular washer sandwich that stretches the skirt as it gets tighter.

Also, perfect seals aren't really necessary. So long as your darts and barrel are a good match, you'll still get around the same performance. In some blasters it turns out that a perfect seal is actually harmful. In most cases it's about e-peen, rather than actual necessity.

Well I guess perfect might not be necessary but it's still worth having the discussion of how to understand how to get a seal to function properly and what things to consider. What exactly is this washer sandwich that you're talking about? When you sandwich the seal between two fender washers are you putting anything inside the seal to match the ID? If not, how do you ensure it's centered? Just eyeballing it and clamp tight enough to ensure it stays? I tried this method first, before I got my part printed. I didn't like how wobbly it felt and the 3D part feels really secure. Also I can't imagine this breaking at all. It's very solid. It's probably similar to the shape of Nom's lathed aluminum plunger heads but I haven't seen a write up where he explains exactly how he does those.

So to sum up you suggest A fender washer, a circular piece of polycarb (1/4" thick?) with a #6 bolt hole in the middle, and another fender washer. Then put this whole thing on top of the square rod. What diameter would you suggest for that circle of polycarb?

My design is fairly similar but the rear fender washer and circular piece of polycarb are one piece and they are printed together out of ABS. I could achieve the sandwich pressing effect that you're talking about simply by making the shaft part of my piece slightly too short. I that's a great idea, I'll try that.

-mike

#4

Posted 29 October 2013 - 03:00 PM

I have a significant amount of experience with different filaments, and it is definitely not in any way impact resistant.

I'll second the thought that it could break.

http://nerfscience.blogspot.com/

#5

Posted 29 October 2013 - 04:14 PM

Printed ABS is not that strong.

I have a significant amount of experience with different filaments, and it is definitely not in any way impact resistant.

I'll second the thought that it could break.

Alright, perhaps 3D printing this isn't the way to go. So I'll try another material for the next one and see how the current one holds up. But assuming the materials hold up, is there a better shape to use to make the seal? It seems like the current best suggestion is to put a circle of polycarb inside the skirt seal and sandwich it between fender washers. I'm looking for suggestions on the diameter and thickness of that sheet of poly carb. What makes the best seal? Or does it not even matter because the sandwiching action of the washers is going to do that work for me?

-mike

#6

Posted 29 October 2013 - 04:51 PM

#7

Posted 29 October 2013 - 06:29 PM

#8

Posted 29 October 2013 - 07:10 PM

Also, NOM's aluminum plunger heads are made by roboman on his precision metal lathe.

Edited by quertyman, 29 October 2013 - 07:17 PM.

#9

Posted 29 October 2013 - 09:21 PM

Also, NOM's aluminum plunger heads are made by roboman on his precision metal lathe.

They are indeed. You can't really make one without a lathe, which I'm assuming you don't have. If you do have one, they're not terribly difficult to make, and take about 30 minutes once you get good at it.

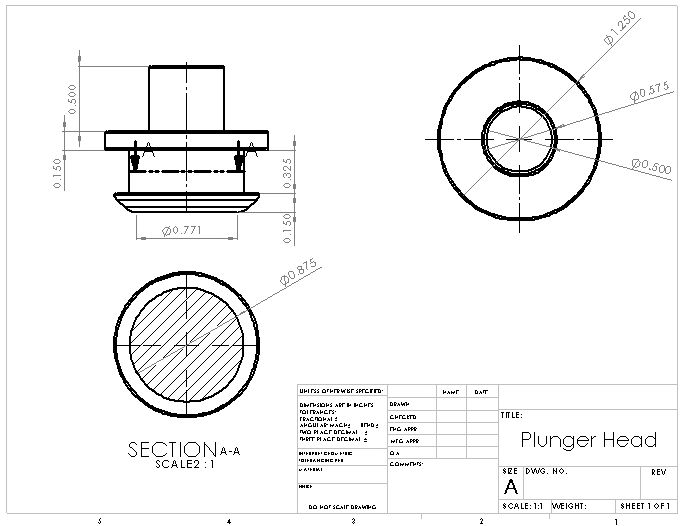

Here's a drawing that isn't to any particular standard but should be good enough for anyone's purposes here.

Edited by roboman, 29 October 2013 - 09:22 PM.

Youtube

LS and Retaliator boltsleds are currently available at https://www.facebook.com/RoboM8/

#10

Posted 30 October 2013 - 01:06 PM

Really just a simple sandwhich will do, it must be tightened down to the correct force. Not that it matters much. If you scroll down in my writeup I show how I make a good looking (opinion) plunger head with just 2 circles of polycarb. Here's a nice clear pic of how I did it. The screw size in the middle doesn't matter as long as it is 1" or longer. It seals absolutely perfectly and is (opinion) low friction.

Oh it looks like you don't even have anything on the inside diameter of this skirt seal, is that correct? Do you ever have problems with it either sliding side to side or getting it lined up so that it's exactly concentric with the polycarb disks?

They are indeed. You can't really make one without a lathe, which I'm assuming you don't have. If you do have one, they're not terribly difficult to make, and take about 30 minutes once you get good at it.

Here's a drawing that isn't to any particular standard but should be good enough for anyone's purposes here.

Oh thank Roboman. This is quite helpful, I do have access to a lathe. I made a 3D model of your part for reference: http://www.thingiver...om/thing:174234

I have a couple of questions to clarify about this.

1) It looks like this is one whole piece. It doesn't come apart does it? If so I guess you can't adjust how much the seal is being clamped down. 0.325 height compared to 0.375 height on the seal is squishing it a little bit. Did you play with that height to improve the seal or does it not matter?

2) I assume you just stretch the seal over the head and to put it on, right?

3) Why is there so much distance behind the seal's backstop? You have half of an inch behind it. Is this to keep it stable and concentric with the plunger rod?

4) What is the diameter of the cone's widest part? I couldn't figure that out. Is it documented in there? I just guess 0.9*1.25

-mike

#11

Posted 30 October 2013 - 01:25 PM

Oh thank Roboman. This is quite helpful, I do have access to a lathe. I made a 3D model of your part for reference: http://www.thingiver...om/thing:174234

I have a couple of questions to clarify about this.

1) It looks like this is one whole piece. It doesn't come apart does it? If so I guess you can't adjust how much the seal is being clamped down. 0.325 height compared to 0.375 height on the seal is squishing it a little bit. Did you play with that height to improve the seal or does it not matter?

2) I assume you just stretch the seal over the head and to put it on, right?

3) Why is there so much distance behind the seal's backstop? You have half of an inch behind it. Is this to keep it stable and concentric with the plunger rod?

4) What is the diameter of the cone's widest part? I couldn't figure that out. Is it documented in there? I just guess 0.9*1.25

-mike

1) You don't need to clamp down on the seal with single piece plunger heads. You will get a perfect seal if you make it correctly. The thickness of the parts of the seal that actually touch the plungerhead is .325". There should be no squishing involved.

2) Yes.

3) It gives you more area to attach the plunger head to the rod. I like to cross-drill it and press a .125" stainless roll pin through the head and rod. It's permanent and the pin has a shear strength of something like 1200 lbs, so the plunger rod or head will fail long before that pin does.

4) 1.125". I guess I missed that dimension.

Youtube

LS and Retaliator boltsleds are currently available at https://www.facebook.com/RoboM8/

#12

Posted 30 October 2013 - 05:05 PM

That is correct. And not at all. The way I sanded it made it sorta fall into place. But that isn't even necessary. Heres a pic of my plusbow plunger head. Also a perfect plunger head seal. Not the best pic but it gets the point across.Oh it looks like you don't even have anything on the inside diameter of this skirt seal, is that correct? Do you ever have problems with it either sliding side to side or getting it lined up so that it's exactly concentric with the polycarb disks?

-mike

#13

Posted 31 October 2013 - 07:19 PM

Printed ABS is not that strong.

I have a significant amount of experience with different filaments, and it is definitely not in any way impact resistant.

I'll second the thought that it could break.

If your design and printer settings are sensible, 3d-printed plunger heads won't be a problem strength-wise. At this scale, there's no reason not to print them solid, and if your extrusion multiplier is high enough the strength difference between this and solid ABS won't be too large. I have thousands of dry fires using a 3d printed ABS plunger head without signs of wear, although the responsible thing would be to glue a bit of rubber on top anyways.

Getting a perfect seal with them is another story, and it may or may not be possible. I don't know exactly how yours is printed, but you want to use the flat bottom from your printing surface to seal against the bottom of the skirt, and then squeeze it against that (yes, this plunger head needs multiple parts). Even then, the printing process may have left tiny, invisible channels through which air can pass. Increasing the 7/8"-ish holding diameter may or may not have an impact on your seal, I'm really not sure. If you're willing to sacrifice/dedicate the skirt to this project, you might also try supergluing the base of the skirt to the aforementioned flat surface.

I have used 3/4" CPVC to mount these skirts before, and it sealed better than any other plunger head I've made. However, the design consisted of end-caps on both sides of the skirt, pinching it, and instead of a plunger rod I had a string knotted and glued up inside the plunger head. Since this is for a Rainbow, the plunger head really needs to mount to a 1/2" shaft, which is very difficult to do with 3/4" CPVC and have it seal perfectly.BTW, remember your CPVC tubing. The OD is always the nominal plus 1/8". So a 3/4" CPVC bushing would be great, going by what I see here.

I've also turned plunger heads out of plastic (polyethylene and delrin) on a lathe with great success, but it was very time consuming , partly because my lathe chuck has trouble holding on to the workpiece, especially plastic. It's not terribly hard to make these seal well, but all the guns I've used them with had other sources of leakage so I don't know if they really sealed perfectly.

Edited by KaneTheMediocre, 02 November 2013 - 08:42 PM.

#14

Posted 03 November 2013 - 01:44 PM

If your design and printer settings are sensible, 3d-printed plunger heads won't be a problem strength-wise. At this scale, there's no reason not to print them solid, and if you're extrusion multiplier is high enough the strength difference between this and solid ABS won't be too large. I have thousands of dry fires using a 3d printed ABS plunger head without signs of wear, although the responsible thing would be to glue a bit of rubber on top anyways.

Yeah I know, itś plenty strong. I just conceded the point because I it's likely strong enough and I didn't want to delrail this thread, which is much more about the shape. I plan to 3D print these just because it's so easy and cheap for me as I have access to a couple printers. I might switch to machining them from aluminum as well, if they ever break or I just want to try it. But that's not really what this is about.

Getting a perfect seal with them is another story, and it may or may not be possible. I don't know exactly how yours is printed, but you want to use the flat bottom from your printing surface to seal against the bottom of the skirt, and then squeeze it against that (yes, this plunger head needs multiple parts). Even then, the printing process may have left tiny, invisible channels through which air can pass. Increasing the 7/8"-ish holding diameter may or may not have an impact on your seal, I'm really not sure. If you're willing to sacrifice/dedicate the skirt to this project, you might also try supergluing the base of the skirt to the aforementioned flat surface.

Squeezing seems like the big peice of advice from this thread that keeps coming up and I had never really considered. Roboman's don't squeeze, so it's worth trying that out but I think I'm also going to try a squeezing technique as well. Basically I will take the design that I've posted to thingiverse and make the shaft that goes inside the seal slightly shorter. Then I'm going to cap it off with a rubber fender washer as well as a metal fender washer. I think this should be pretty good.

-mike

#15

Posted 03 November 2013 - 03:50 PM

#16

Posted 03 November 2013 - 04:04 PM

I know everyone has a hard-on for skirts squashed between polycarbonate disks, but I have to point out that it's trivially easy to get a perfect, low-friction seal with neoprene washers and silicone grease. If you're having a lot of trouble with the former, why not try the latter?

The silly part about skirts is that they are actually designed to seal on the front edge, against a flat surface. U-cups, on the other hand, are 1/4 the price of skirts and are actually designed to seal against a tube in a plunger. I agree about the neoprene washers, though. Also far less expensive and work great, easily. Especially since most homemades are ridonk over-powered.

[15:51] <+Rhadamanthys> titties

[15:51] <+jakejagan> titties

[15:51] <+Lucian> boobs

[15:51] <+Gears> titties

[15:51] <@Draconis> Titties.

[15:52] <+Noodle> why is this so hard?

#17

Posted 03 November 2013 - 04:05 PM

Edited by Draconis, 03 November 2013 - 04:07 PM.

[15:51] <+Rhadamanthys> titties

[15:51] <+jakejagan> titties

[15:51] <+Lucian> boobs

[15:51] <+Gears> titties

[15:51] <@Draconis> Titties.

[15:52] <+Noodle> why is this so hard?

#18

Posted 09 November 2013 - 09:33 PM

-mike

#19

Posted 09 November 2013 - 09:50 PM

Maybe we should talk about the benefits of Stretch-to-fit shaft seals (aka skirt seals), ucups, and neoprene washers. What are the relative pros and cons of each?

-mike

I've been able to get consistently better performance out of skirts. U-cups have measurably impacted the performance of my springers - Hoongfu and Koree swapped a u-cup out for a skirt on one of the aluminum plusbows I built, and they managed to get a 40 FPS increase out of it. I've never been able to get a neoprene washer to work without massive amounts of friction, though I'm probably doing something wrong and don't really care to fix it, because 1-piece plunger heads make assembly wicked fast.

Skirts seem to have a smaller contact area than u-cups or washers, and they're made of a higher durometer rubber, so they deform less and tend to have less friction. Performance is also very much dependent on the batch of polycarb tube you receive - the listed tolerances are +/- .040" for the ID, which is a huge margin of error. You simply can't expect a homemade to perform well with a plunger tube that's .040" undersized, because nothing is going to work well as a seal without massive amounts of sliding friction. Unfortunately, there's really no way to avoid this if you're using polycarbonate tube from McMaster as a plunger tube, and I'd imagine PVC isn't much better, if it is at all.

Youtube

LS and Retaliator boltsleds are currently available at https://www.facebook.com/RoboM8/

#20

Posted 09 November 2013 - 11:22 PM

Photobucket

Winning rounds is rewarding, deal with it. We don't play fucking patty cake over here.

#21

Posted 10 November 2013 - 09:53 AM

Skirt seals and neoprene washers seem to have similar performance. It's easier to get a perfect seal with washers, but a 100% seal is not as big of a deal as people make it out to be (low friction is far more important).

#22

Posted 12 November 2013 - 03:15 AM

It could also have to do with your plunger tube and it's inner tolerance. The PVC that I have access to (in Canada) has pretty poor tolerance. When I look inside, it's quite clear that it isn't smooth or uniform.

The other possible factor may be that your plunger head isn't sitting 'square' on the plunger rod with the spring behind it. Many of the springs I've seen people use don't have finished ends. Once the spring is compressed, it can cause the plunger head assemble to be slightly cant. Meaning, that you may have a perfect seal along 2 opposite edges but the edges perpendicular, may be just cant enough to allow air to flow through.

I use drain plugs as my plunger heads. They work great for me.

#23

Posted 12 November 2013 - 09:40 AM

Which is an advantage of using polycarbonate tubing, it is manufactured with smoothness on the inner surfaces in mind. With PVC, only the outer diameter is tightly controlled. PVC works fine with neoprene/rubber washer plunger heads (since they're "squishier" and will flare out into the uneven nooks and crannies), but skirts and U cups sometimes won't seal very well. This isn't a universal problem, some hardware store PVC is smooth enough to get perfect seals with skirts, and most of the tubing you can get from McMaster (such as clear PVC) is quite smooth on the inside.It could also have to do with your plunger tube and it's inner tolerance. The PVC that I have access to (in Canada) has pretty poor tolerance. When I look inside, it's quite clear that it isn't smooth or uniform.

Edited by Daniel Beaver, 12 November 2013 - 09:43 AM.

#24

Posted 12 November 2013 - 09:41 PM

Assemble your blaster without the spring or barrel. Peer down your blaster like a telescope while facing a light source. Pull and push the plunger rod back and forth looking for light around your plunger head. Much like an eclipse. If you can see light, that's where air is seeping through. Ideally you don't want to be able to see any light.

If the light seep is consistent through out the plunger draw then there is most likely a problem with your plunger head assembly. If the light seep is intermittent and random, then the problem more than likely lies on the tolerance of your PVC plunger tube.

This is of course is assuming that you're using clearish poly carb for your rainbow catch. Otherwise, take it out and keep the plunger rod centered another way.

Edited by makeitgo, 12 November 2013 - 09:45 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users