Hello, fellow forgers, this is Hummer. I have crafted a Bolter that fires nerf rounds and has more special features than you can swing a chainsword at.

First, have some photos of the finished product:

“Zion” Pattern Bolter Specs Without Stalker addons:

- 9 Pounds

- 27” Long (Barrel to end)

- 3 1/4” Wide (Side to Side)

- 12” Tall (Iron Sight to bottom of grip)

- 60ft Range

- 2/3 scale of a space marine bolter (Roughly)

- Awesome level: Off the charts

Now I know you're all here to see how I did it, but before we get into the how-to section, I'd like to pause for a moment to emphasize the importance of safety. Demonstrated by Louiec3:

Take careful note of the Buzz Lightyear safety gloves along with the old man glasses. The Wiggles poster reminds us to be safe at all times...

+++ Forging Preparations +++

Special note: Anything with an *Astrix* around it means it not necessary to use/make the most basic form of this bolter.

+++ Tools +++

Scroll saw

Hacksaw

*Band Saw*

Dremel tool

Drill

File

Sandpaper

Hot Glue gun

*Belt Sander*

*Adjustable wrench*

*Lathe*

*Popsicle Stick*

*Lighter*

+++ Materials +++

Nerf Longshot……………………………………..……….……………………………..….........................……($30)

*(2) Nerf Longshot scopes*

*(2) Small Nerf Big Bad Bow Wheels*

*(1) Recon Barrel*

*Bandoleer*……………………………………………….……………………………….........................…..…*($15)

Hot Glue

Wood Glue

*Wood Putty*

Plastic epoxy

(1) 8" wide, 3/4" thick piece of wood…………………….………………………………................….……($3)

(3) Polycarbonate 12" x 24", Clear, 1/4" thick …………..…………………………........……..…....($70)

I got mine on and then searched with this number: 8574K43. If this number does not work, I used 0.125” thick Polycarb.

Resin……………………………………………………………………………………….............................…...….($10)

I got mine at Klockit and then searched with this number: 8574K43. If this number does not work, I used 0.125” thick Polycarb.

Resin……………………………………………………………………………………….............................…...….($10)

I got mine at Klockit and got the smallest bottle set

Aluminum piece for boltsled reinforcement……….…………………………………………........(Freebie)

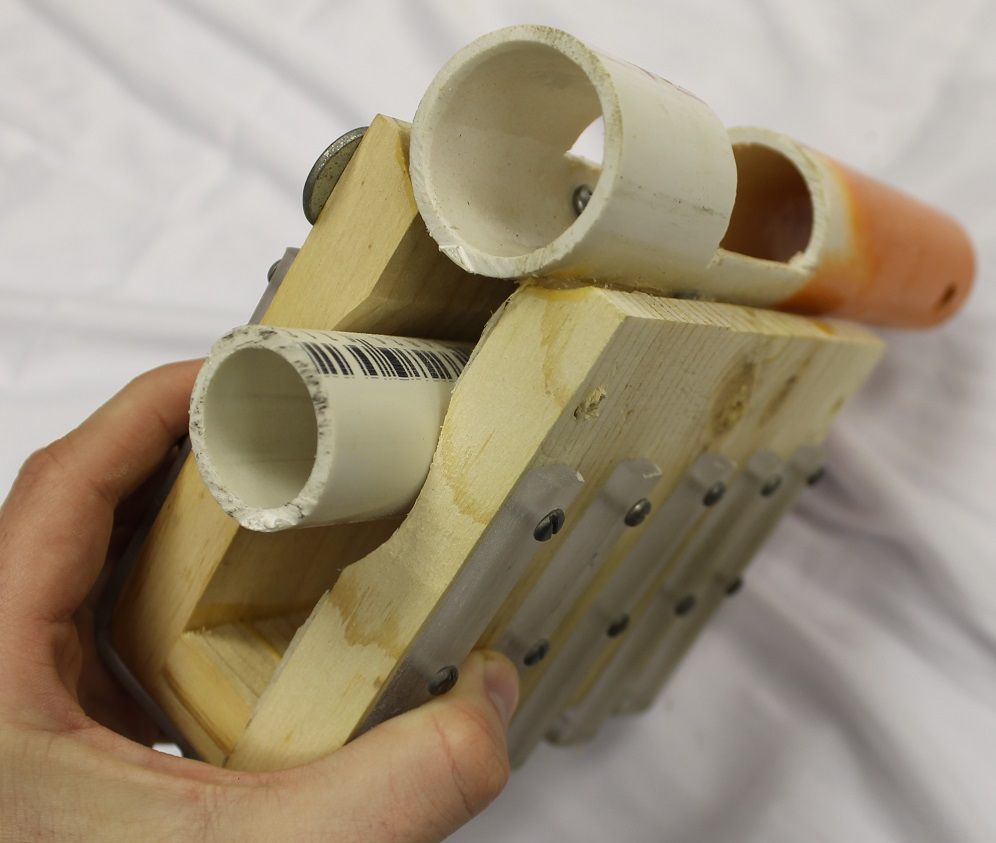

(1) 9 1/2" Length of 1 1/4" PVC……………………...………………………………...............……………..($2)

(1) 8" Length of 3/4" PVC……………………………...…………………………………...................…………($1)

*(2) 8" Length of 2" PVC*………………………………...………………………………...............…….*($3.50)

*(2) 1 1/4" PVC couplers*………………………………...……………………………………................*($0.80)

*(1) 1/2" length of 1/2" PVC………………...………………………………………………...............……..*($1)

Screws........................................................................................................................(Freebie)

Bolts...........................................................................................................................(Freebie)

Washers.....................................................................................................................(Freebie)

*Flashlight*…………………………………………………………………………….......................…………..*($15)

*Sound Card*…………………………………………………………………………………......................…..*($10)

I got mine on ebay, try searching "Recording module with push button"

*(2) 1/2" Wire Rope Clip* (Suitable substitute: U-Bolts)...............................(Freebies)

*(2) 2” Length of 1 ¾” PvC rod*...............................................(Courtesy of Louiec3)

*(1) 4” Length of 5/32" K&S Music Wire*...................................(Courtesy of Louiec3)

*(1) 2 1/2" dia. Magnet*………………………………………………...............………………………..*($7.50)

*Green stuff* ………………………………………....................……………………………………………...*($10)

I got mine at The War Store

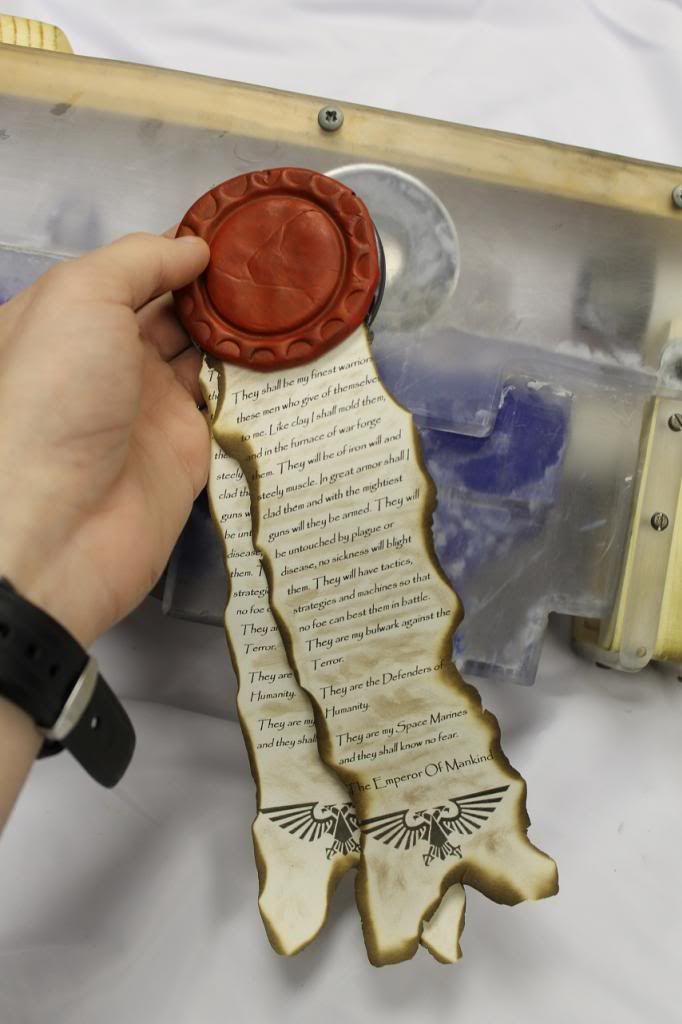

*Parchment-esque Paper*..........................................................................(Freebie)

*Acrylic Red paint*……………………………………...................…………………………………………….*($3)

*Mud-colored wash*…………………………………..................…………………………………………..…*($3)

Base Cost total…….………….....……………...................……………………………………………….$116.00

With all addons total.…….……………...................………………………………………………………$184.80

+++ Forging +++

+++ The Longshot +++

(tl;dr of this section: USE. RESIN.)

You can modify your longshot to your liking, but I highly recommend you do the first on this list:

~ Reinforce the handle with resin; the stock longshot handle is meant to only handle the longshot weight, not all of the weight you will be adding in this project.

Step 1: Acquire the Resin from here or similar product.

Step 2: Follow the directions that come with your resin kit for mixing.

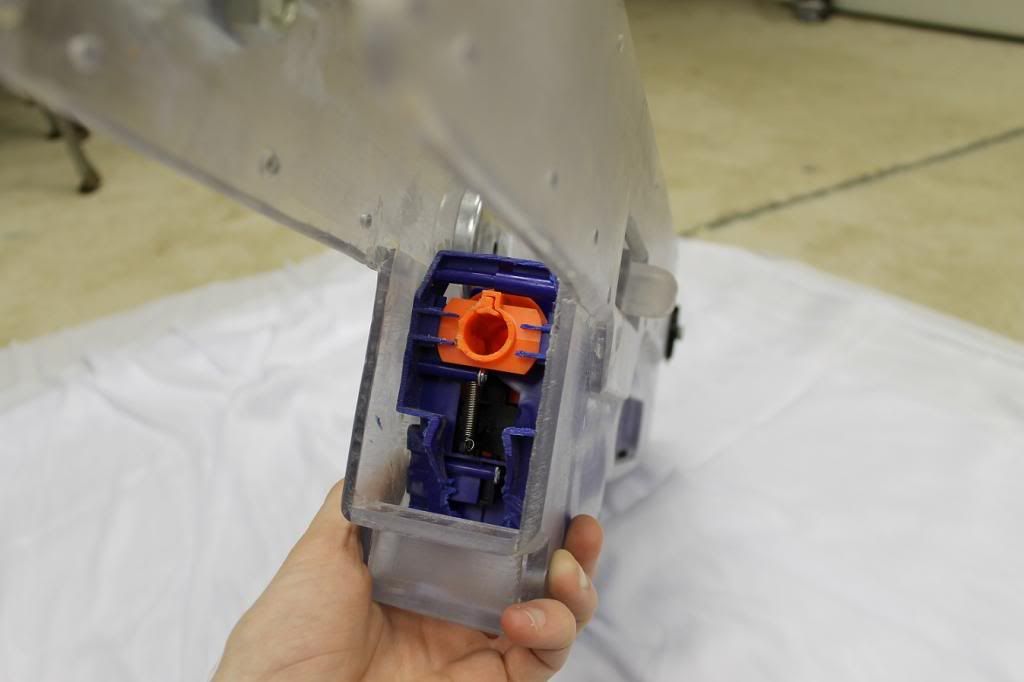

Step 3: Apply the resin to the areas shiny in the picture below: (remember; it's better to use more resin than less)

(Writeup assisted by angry marine Sargant !@#*PUNCHER)

~ If you're doing ANY spring upgrades, do a Boltsled reinforcement. An excellent write-up exists on Oznerf.

(Don't be a cop-out and do the wire hanger thing, it doesn't work as well)

~ How I minimized mine is I simply took the Longshot to a bandsaw and hacked it down to its bare essentials. Take out your internals to avoid cutting them and cut off the front and tactical rail off like so:

+++ Auxiliary modifications +++

~Grip dart storage

Step 1: Cut about a 1/2 inch off of a 1/2 inch pvc piece to hold your dart

Step 2: Open your longshot and pre-mark how much you will need to take out, it is better to undercut.

Step 3: Dremel until half of your pvc piece can rest in the groove. Repeat steps 2 and 3 until this is achieved.

Step 4: Hot glue the PVC into the right side of your longshot, leaving room for the other half to close upon it.

~ Make yourself a new priming handle, it will look better cosmetically.

Step 1: Take your 2” Length of 1 ¾” PvC rod and take it to a lathe and remove a ¼” deep by ½” long section. Repeat for the other side. They should look like this:

Step 2: Take a 5/32 drill bit and drill in the center of both pieces of PVC 1” deep. Take your 4” Length of 5/32" K&S Music Wire and coat one end in super glue and stick it into one of the PVC pieces. Apply less to the other side when you’re finished with your blaster.

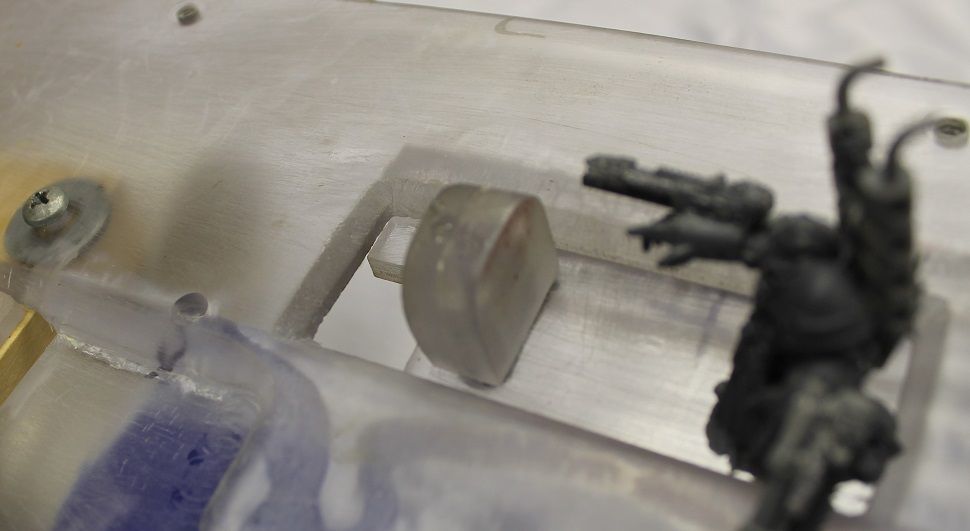

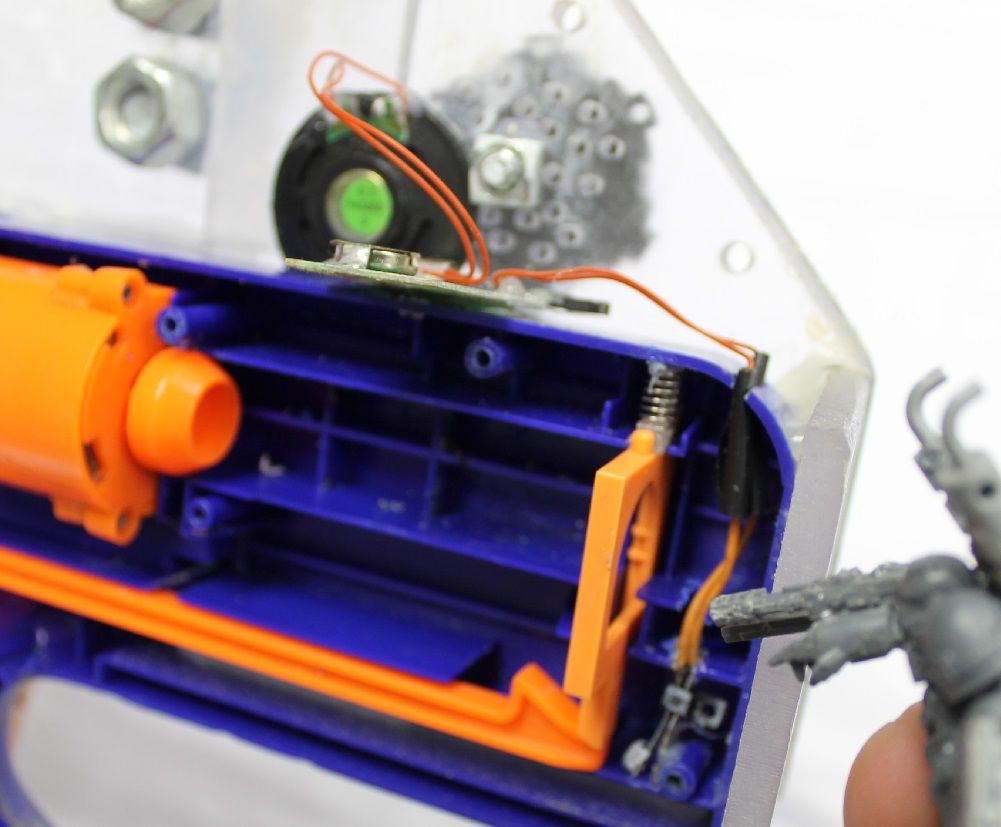

~ Make your Bolter roar even when it’s not loaded by adding a sound card.

Step 1: Load a suiting sound onto the sound card. I just recorded the sound of the Stalker bolter from the space marine game. If you’re using the model of sound card I used, here is the video the manufacturer provides: [url]

Step 2: Find some form of spacer to put behind the button. I used a small nut.

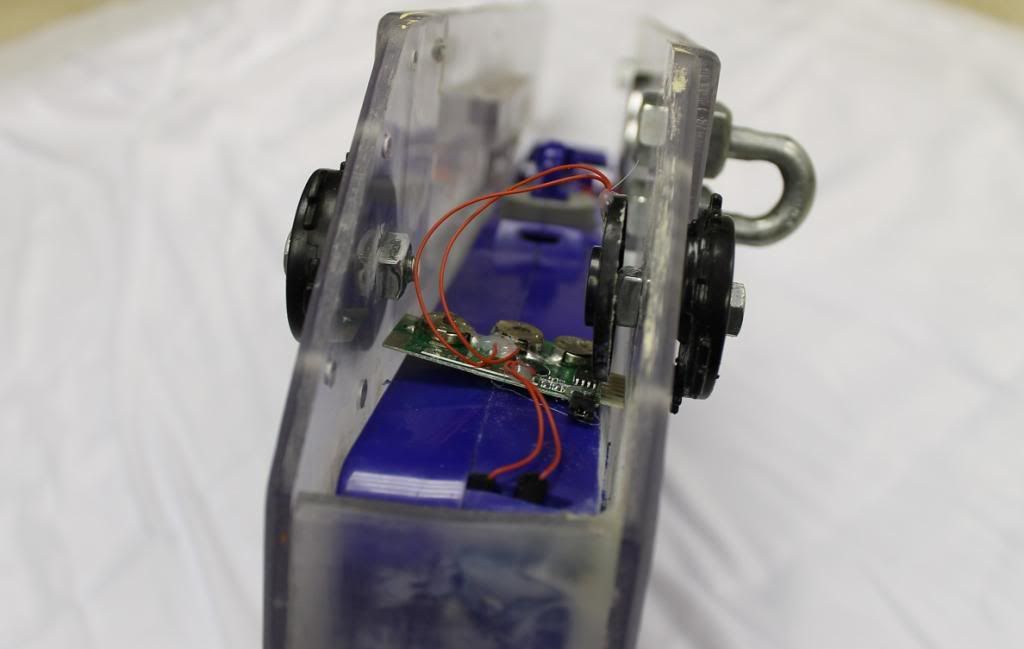

Step 3: Cut along the back with a dremel tool to run the wires through like so:

Tip: To help the sound project better, I drilled holes in the polycarb on the side and covered that with a Big Bad Bow wheel. The magnetic field from the speaker allows it to just stick to the bolt I ran through the BBB wheel.

Step 4: After checking to see that the longshot trigger will set off the sound card, attach it with superglue and/or hot glue.

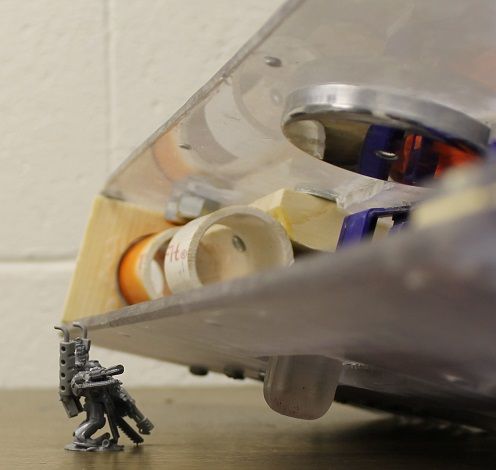

+++ Polycarbonate +++

(tl;dr of this section: cut some polycarb, slap it on the sides and back with super glue)

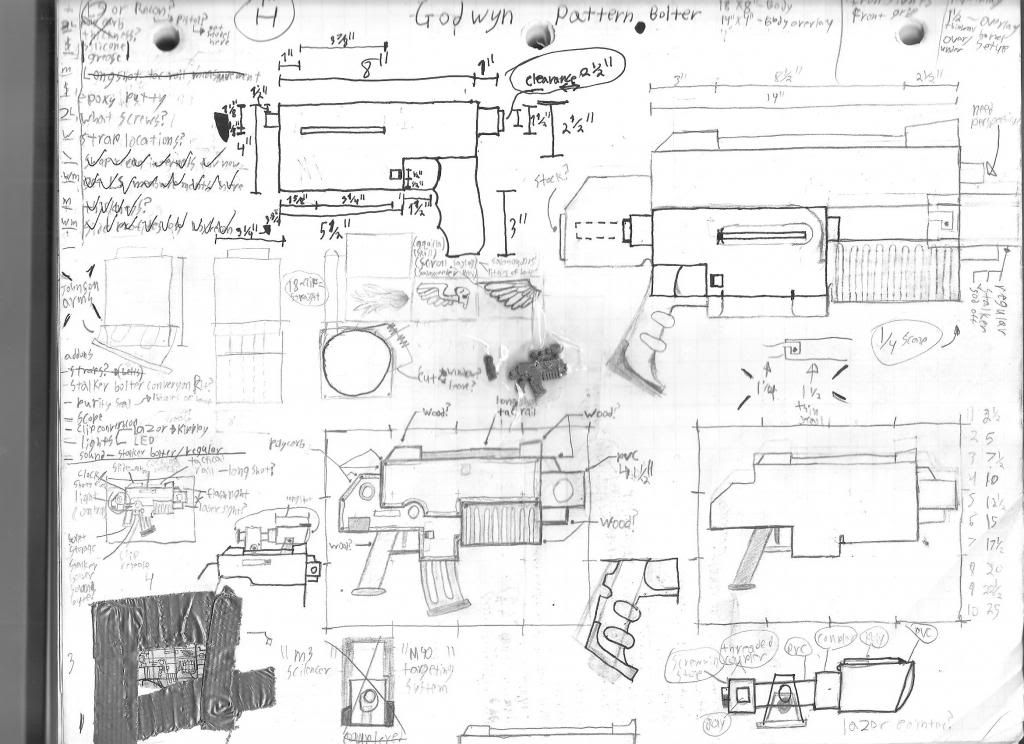

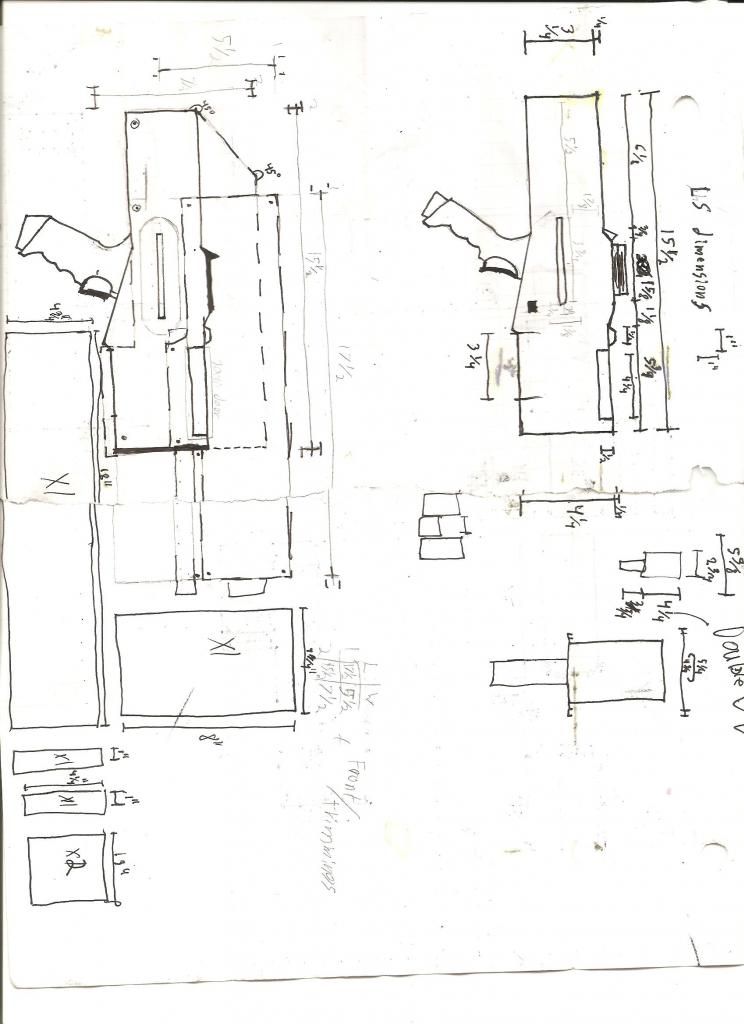

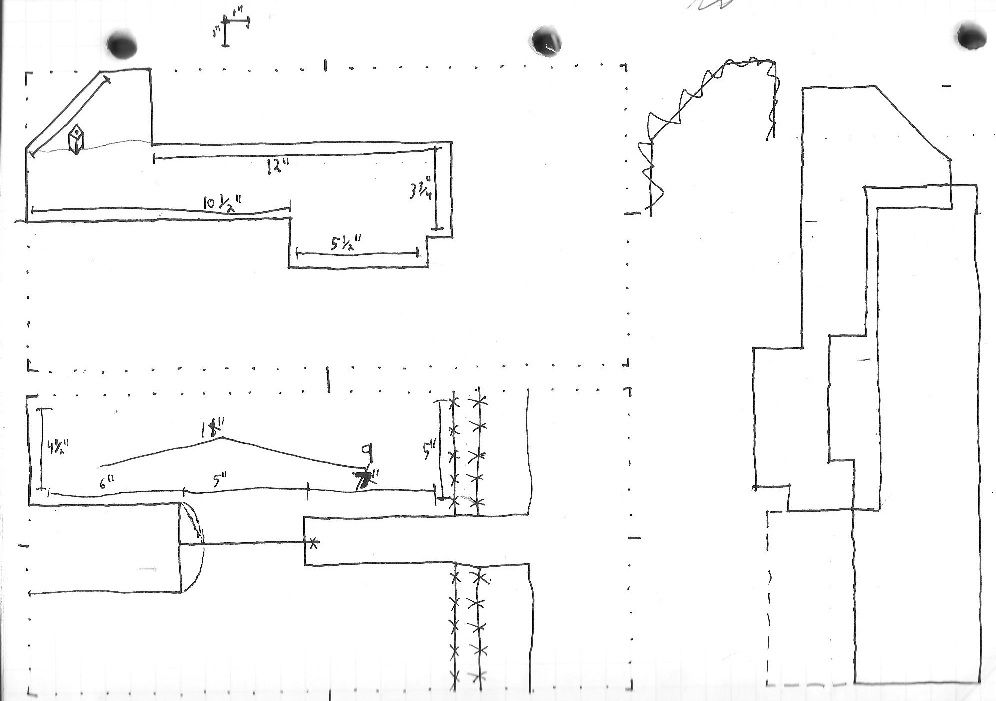

Here is a rough drawing of what I cut out and how they go together on the sides:

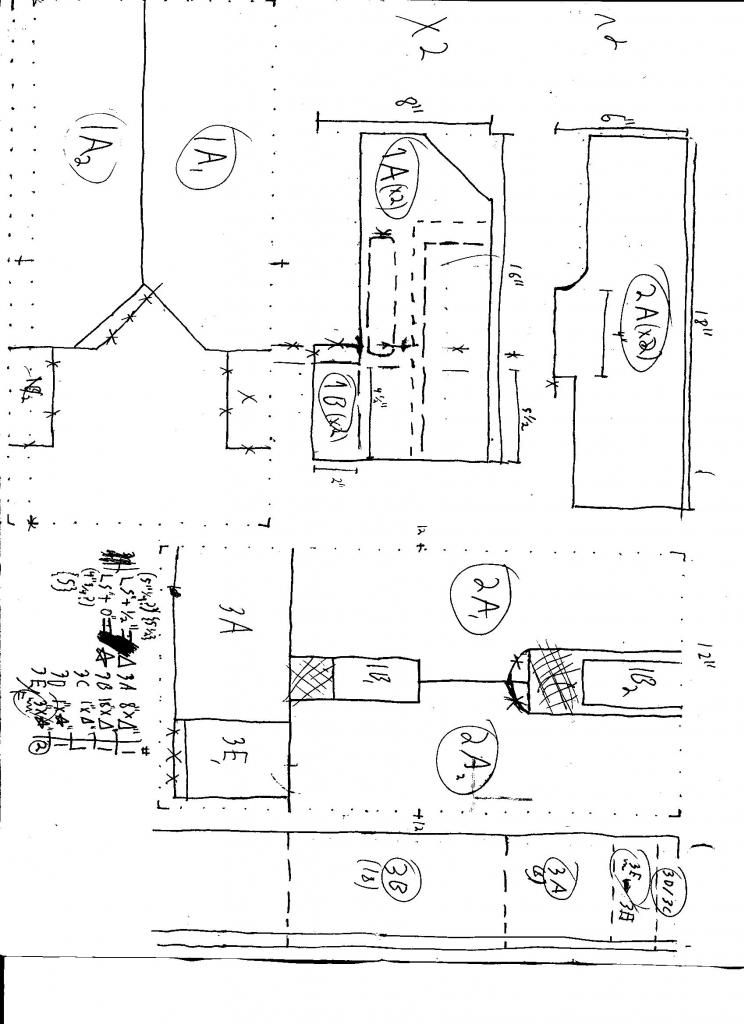

Once you print out the templates, glue them to the Polycarbonate (make sure you didn't take the shielding on the polycarbonate off)

Once they have dried, take it to the scroll saw and cut it out. Once that is done, double check to make sure you have the shape you want.

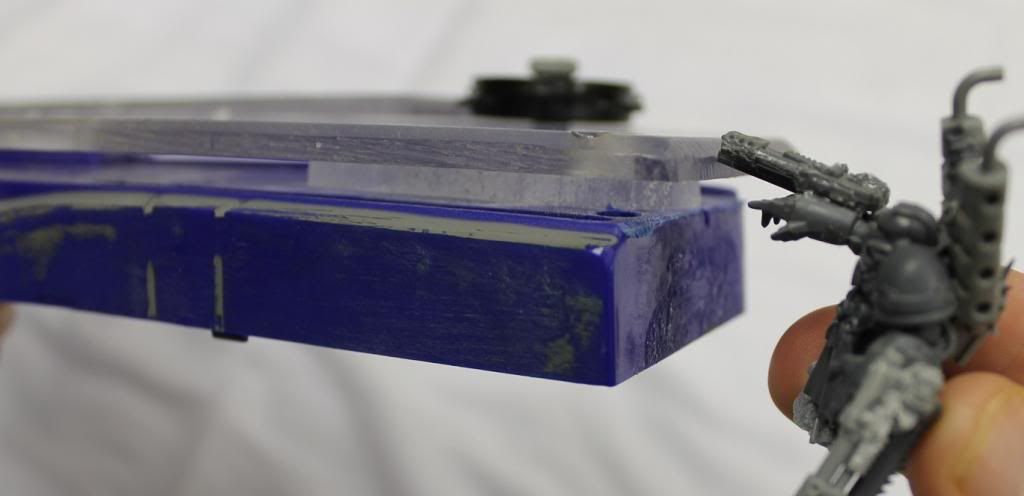

Once you have that figured out, cut out some medium sized pieces for spacers between the Polycarbonate and the deeper part of the longshot, like these:

Remove the shielding from both sides of the medium-sized pieces and sand both the pieces and the areas they will be attached to for greater adhesion. Once sanded, apply Super glue and apply the medium pieces. Once that is completed, start to position the Polycarbonate on the side(s) of the longshot (you should be imagining it like the following pictures)

Once you're sure where you want the pieces, remove the shielding, sand where they'll be attaching to each other, pre-assemble the 2 pieces with super glue, let that dry, then attach the side to your longshot. When attaching to your longshot, MAKE SURE it's level or at least make sure both sides are both equally on a slant. The end result should look something like the above pictures.

After that is completed, cut a piece that covers the back of your longshot. Make sure you only apply superglue to just the right or left side of your longshot so you can open it again.

Once the super glue has dried, reassemble your longshot. You should run into a problem of not being able to access the longshot screws. Just note on the Polycarbonate where to drill and do so.

[Continued in part 2]

Edited by hummer, 29 May 2013 - 10:16 PM.