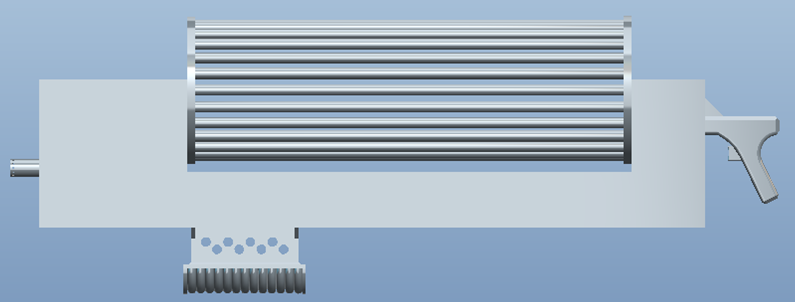

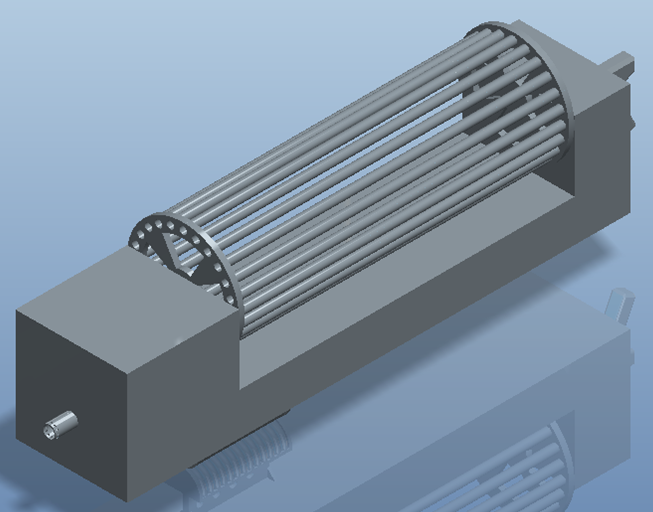

I have recently been working on a homemade (totally homemade, not a single nerf gun part in it) flywheel dart launcher. I have got the basics set up (brushless motors, ESCs, microcontroller etc. on a test rig, but I have been totally stumped on the flywheels! I have tried alloy pullies, but they were off-balance and created way too much vibration. I also tried pieces of polyethylene plastic (cutting board) cut to shape with a hole saw. This was able to be spun up to full speed, but still created a lot of vibration. I loaded 10 streamline darts into a piece of PVC pipe, positioned it in front of the wheels, and blew the darts down it. It fired them all out in about half a second. I tried balancing them (the wheels) with a precision balancer (the type used for balancing model airplane propellers), but the vibration and noise was still pretty awful, and I think It has been damaging the motor bearings.

Anyway, that little rant aside, does anyone have any good ideas for what I could use as flywheels? It would need to be strong enough to be spun at 10,000 RPM, and be well-balanced enough to not start an earthquake.

Any advice would be much appreciated.

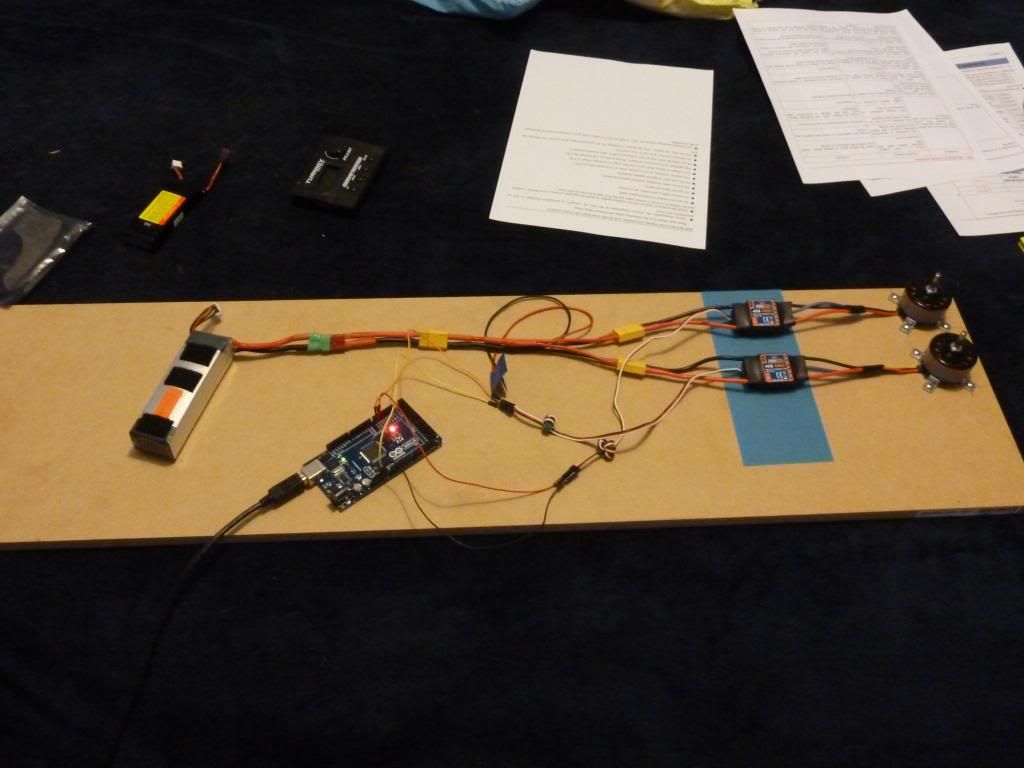

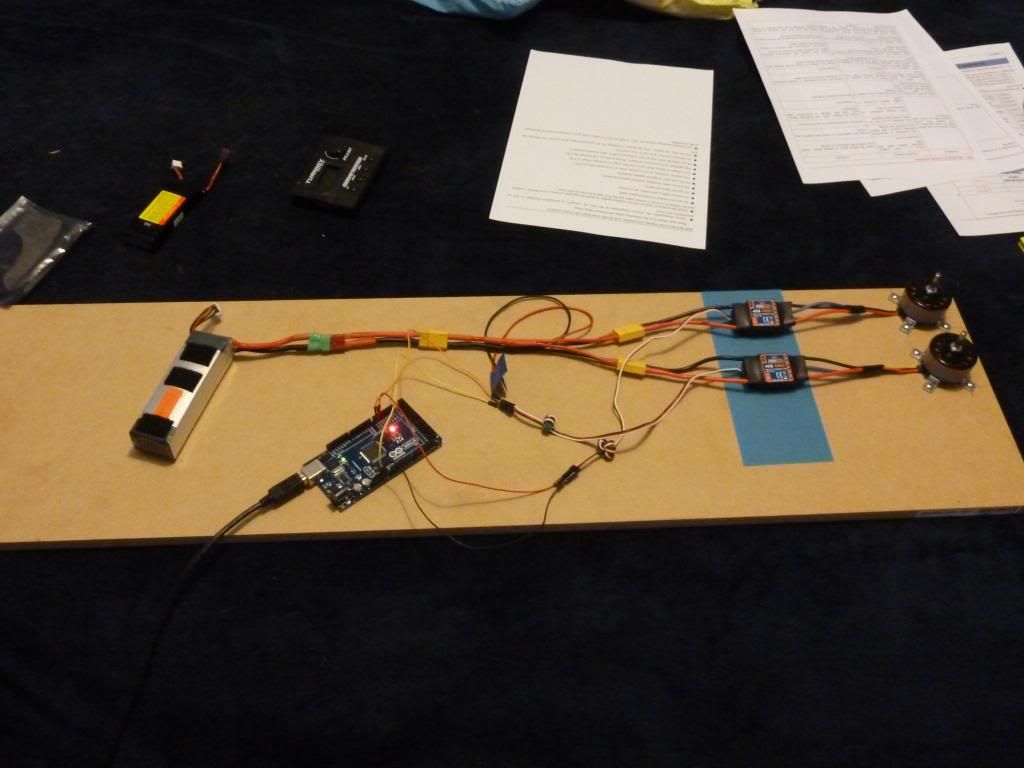

The device on the test rig (before I added the flywheels)