This will be my first proper write-up! Let me start out by saying this mod is not for those on a tight budget. Should you choose to accept this quest, your components are going to run you $100+. You might think this is a little over-the-top, but you'll put those feelings aside when you see how well it performs. This will be the powerful thing that I have ever created, and it's all thanks to getting inspired by this writeup from SGNerf! I got the components from SGNerf, but I followed Ryan Mc#'s writeup for the modding. Without further adieu, let's create a monster!

Required Materials:

Clockwise from top left:

- 3846K431 - Multipurpose Gauge, Steel Case, 2" Dial, 1/8 NPT Center Back, 0-100 PSI connected to 5779K129 - Nylon and Nickel-Plated Brass Tube Fitting, Adapter for 1/4" Tube OD X 1/8" NPT Female Pipe

- 1096T2 - Nylon/Nickel-Plated Brass Check Valve with Fitting, 1/4" Tube OD X 1/4" Tube OD, Buna-N Seal

- 50265K2 - Multirange Brass Pop-Safety Valve, 1/4 NPT Male, 25-200 PSI connected to

- 5779K131 - Nylon and Nickel-Plated Brass Tube Fitting, Adapter for 1/4" Tube OD X 1/4" NPT Female Pipe

- 2x 5779K34 - Nylon Tee for 1/4'' Tube OD

- Schrader to 1/4'' Push-to-Connect adapter from This ebay listing (might be gone)

- Topeak Mini G dual action bike pump from http://bikes.oversto...ouseonline.com/

-

5181K231 - Crack-Resistant Polyethylene Tubing, .170" ID, 1/4" OD, .04" Wall Thickness, Red, 50' L

For my barrel material, I went with 2044T43 - Cut-to-Length Round Plastic Tube, .53" Inside Diameter, 4' Length. This tubing is made of polyethylene and is WAY cheaper than Mcmaster's PETG tubing. It is moderately strong when all six barrels are glued to a couple of turret spacers. I will be using 13'' barrels for this blaster.

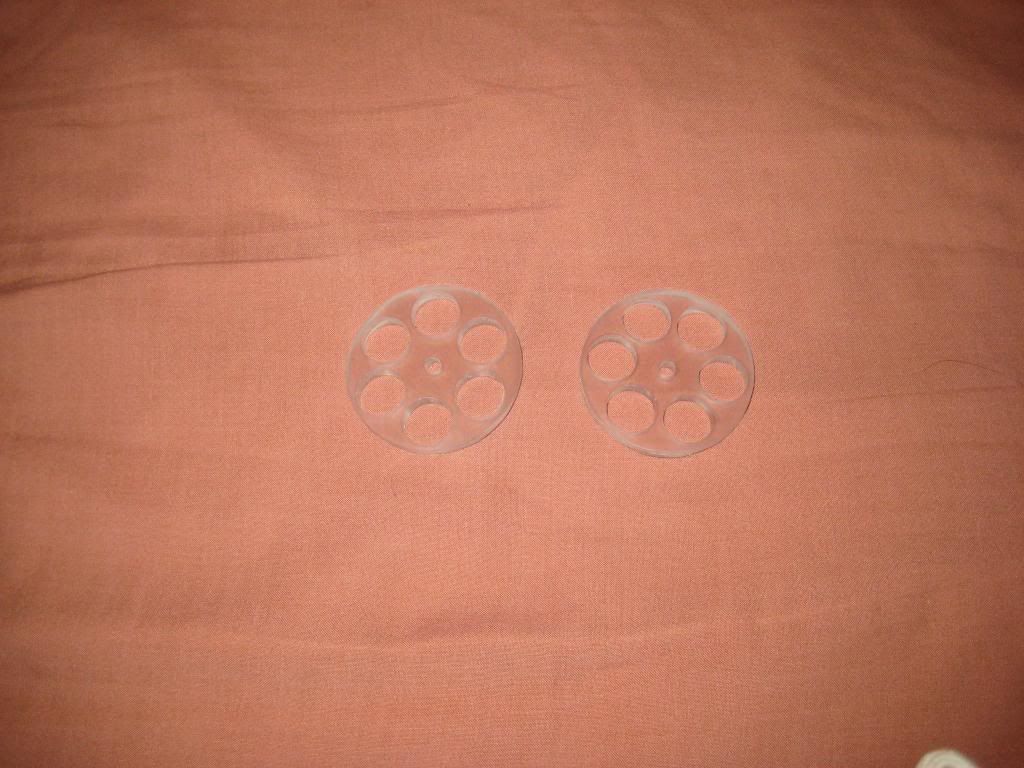

This is a pair of barrel spacers made by Venom213 of Nerfhaven. His sales page for these is here. They serve to keep the barrels perfectly aligned as well as adding structural integrity to the entire turret. I went with 19/32'' holes to fit the Mcmaster polyethylene tubing perfectly.

On the left is 1/8'' oil-resistant Buna-N rubber, Mcmaster part # 8635K164. This is what I use for my air tank to turret seals these days. It works magnificently! On the right is some Vinyl (PVC) tubing that I got at Orchard Supply Hardware. I decided that the 25 feet of polyethylene tubing I bought is too rigid. Yeah, I know--I'm an idiot for buying 25 feet of it. The problem with this project is that you have to cram a lot of components into a relatively small space. Inside the AT3K shell a lot of the space is taken up by the trigger, firing pin, and air tank. I needed flexible tubing to do the job, so that's the explanation for that one.

Write-up:

- Start by taking the blaster apart. Don't worry--there aren't any glued on pieces that require boiling water on this blaster! However, there are very small nubs along the rim of the shell that fit into very small holes in the other half. If you bend the shell too much getting the two halves apart, you risk snapping off some if these nubs. I don't think they're essential, since there are enough screws to hold everything together.

- Remove the turret by unscrewing the screw at the rear end of the rotation mechanism. When disassembled, it should look like this:

- Drill 1/2'' holes into the back of the turret and chop down the barrels. It should look like this:

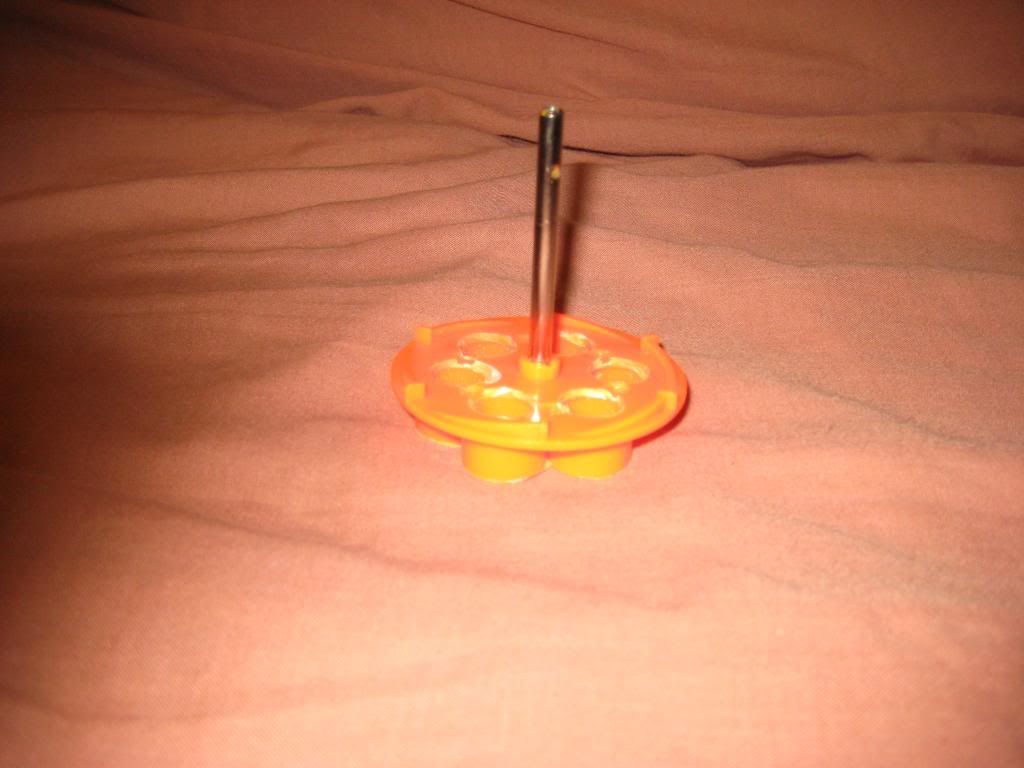

- Cut 6 pieces of polyethylene tubing (or whatever barrel material you use) into equal lengths. I went with 13'' barrels--the rationale behind this was that a proper Supermaxx 1500 takes 12'' barrels and the AT3K has a bigger air tank. Insert your barrels into the orange turret; they should slide in perfectly with no dremeling! Then slide your barrel spacers over the barrels into the spots you want them to occupy. Move them slightly, then mark a dot with a sharpie on each barrel at equal lengths away from the spacer. This will mark the spot where you will glue. Slide the spacers back into position over the black dots. Now you will go one at a time--pulling a barrel out slightly, applying glue at the base and at your black dots, then twisting it into position. When complete, it should look like this:

- Now it's time to dremel down the shells. I dremeled behind the handle--this opening will house my pop-safety valve. Cut a hole in the top half of the shell for rear loading. I agree with Ryan McNumbers's statement that any air blaster that isn't rear loading sucks to use. You will also need to dremel a slot on both sides of the shell in front of the trigger guard to house the bike pump. Dremel out a hole in the back of the blaster for the PSI gauge--I basically just got rid of the "bump" that stick out of the rear of the blaster. It should look like this:

- Now it's time to prepare the air tank. Take everything out except the air tank unit itself. The rotation mechanism will be discarded for this mod guide, since the Topeak bike pump isn't compatible with the rotation mech. I used two pieces of 1/8'' Oil-resistant Buna-N rubber and epoxied them onto the air outlet. This will allow for a perfect seal with the turret! After the epoxy cures, I am going to hot glue a "half-pipe" piece of CPVC onto the side of the air tank to act as a dart-loading guide. Your air tank should look like this:

- Now it's time to reassemble the turret. Lube up the rubber and the entire back of the turret so you can minimize the friction between the plastic and rubber. I also sanded down the back of the turret with fine sandpaper to eliminate any sharp edges that might file down the rubber. I took a piece of CPVC and cut it in half length-wise to act as sort of a "dart-loading guide." Hot glue it to the air tank. You'll notice that if you rotate the turret, the back of the metal turret shaft spins freely and gets kind of stuck. You will need to glue something to either the air tank or the inside of the blaster's shell to keep the rotation mech in place. I used a piece of CPVC. To secure my bike pump to the shell, I will be using velcro straps. I took a piece of clear PVC and glued it near the bottom of the shell to keep my front velcro strap from sliding back. After that, it's finally time to screw down the air tank assembly! Here's what everything should look like:

- I can't believe it's finally time for the bling! Time to turn the AT3K into a pneumatic uber blaster that would make any pimp proud. The trick is to get everything to fit without interfering with the trigger. Years of Tetris have made me an expert as saving space, so study the picture carefully. I decided to attach the PSI gauge with hot glue instead of brackets--I think it looks a lot cleaner this way. Also notice the piece of 3/4'' PVC behind the trigger--this was essential in preventing the trigger from riding upwards. If you remove the stock pump, there is nothing to guide the trigger smoothly and straight backwards. I hot glued a cylinder of 3/4'' PVC onto a small piece of 3/4'' PVC as a riser. Hot glue is good because you get infinite tries--it took me quite a few to get my alignment perfect. The pop-safety valve is hot glued into place as well. I glued my firing pin spring because I didn't have any small, super-strong springs that could handle 70 psi, which is what I intend to operate this blaster at. Tetris FTW!

- Finally, it's almost that time. The moment that took so much blood, sweat, and tears to reach--victory is near! It's time to put together both halves of the shell--I had to dremel down a little nub on the top half of the shell to get things to sit correctly. I used a couple strips of Velcro to hold my air tank snug against the shell. you can see the piece of clear PVC that serves as a Velcro spacer in the first picture. The gap I dremeled fit the Topeak pump almost perfectly! I hot glued the PSI gauge to the back of the shell as the final step and it seems to be holding pretty well. Isn't she beautiful? I'll have fps data coming soon!

Performance:

Fellas, the Chrony results are in! The numbers are, as they should be, staggering! 2 pumps gets me slightly higher that 200 feet per second, and 3 pumps got me up to a maximum velocity of 341.5 feet per second! That was at 62 psi with #6 slug darts. This AT3K is officially banned in American paintball arenas

Cheers!

~T da B

Edited by T da B, 30 January 2013 - 05:35 PM.