The SNAP-7 Megabow with FlipFire® Background:

Background:It all stems from the fact that I love Defend the Core. My loadout for the game has always been something with pump action to clear the way, and then something to dump a huge amount of darts in when I got close. Recently, midwest rules for the game have changed to allow for scoring differences for large ammo. When the rocket contest came up, I saw it as a great opportunity to finally build the dual-ammo blaster I've always wanted.

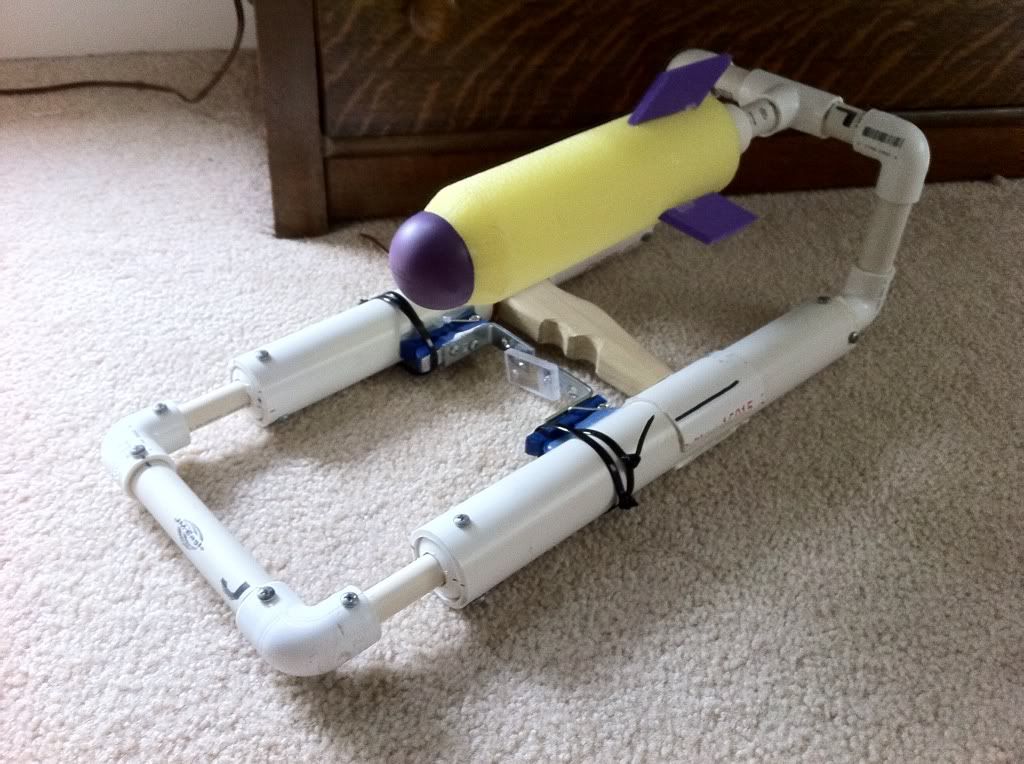

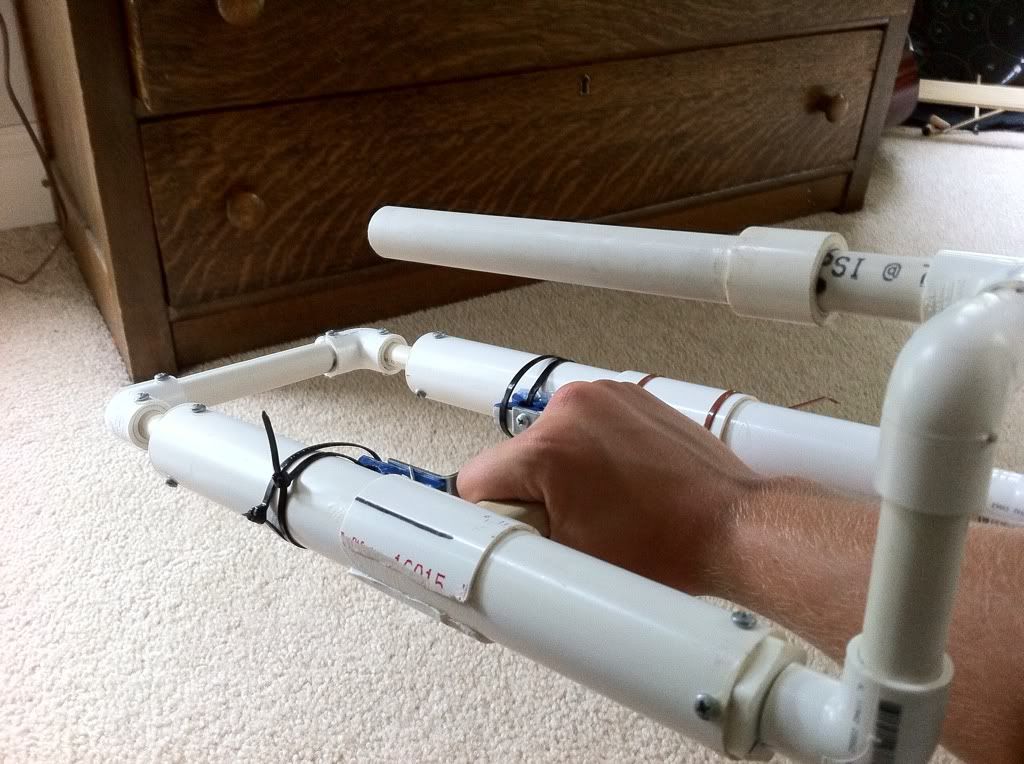

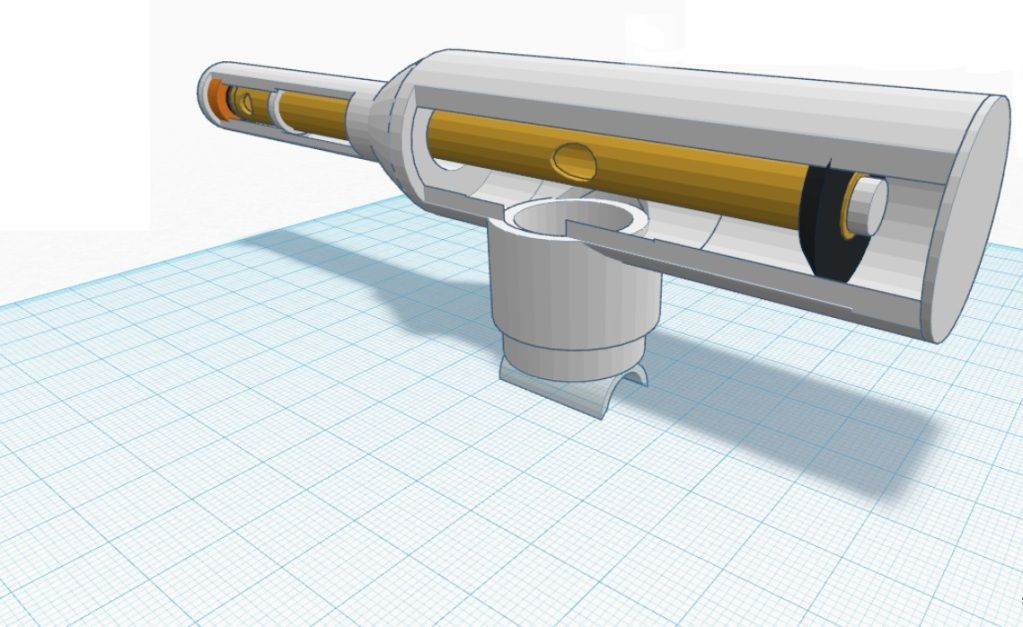

My plan had to build a pump-action blaster with valve selectable barrels, but I didn't like that...like I was gonna take the time to flip valves while rushing the core. So, this blaster makes barrel selection as easy as possible: whichever barrel is on top is the one that will fire. I got the concept from the original Mad Scientist of NH, 3DBBQ: the tee directly in front of the plunger has a large metal bearing inside. It naturally seats against the pipe at the bottom of the tee, sealing off that barrel. Flip over the bow, and it moves to the other side. A bow is a natural for this kind of valve, as it doesn't matter which side is up.

Parts List:Plunger tube:

~3' 2" PVC

2" coupler

2" -> .5" reducing bushing

Plunger rod:

.5" CPVC

.5" CPVC tee

1.25" endcaps

Small section of 1.25" PVC

Cotter pins

2.5" rubber washer

Bolt, nut and and finishing washer

Bow arms:

2x 3/4" 45 degree bends

3/4" PVC

1" PVC

1.25" tee

3/4" coupler

Bowstring

Barrels:

2x 3/4" tee

hopper barrel setup

2x 3/4" elbows

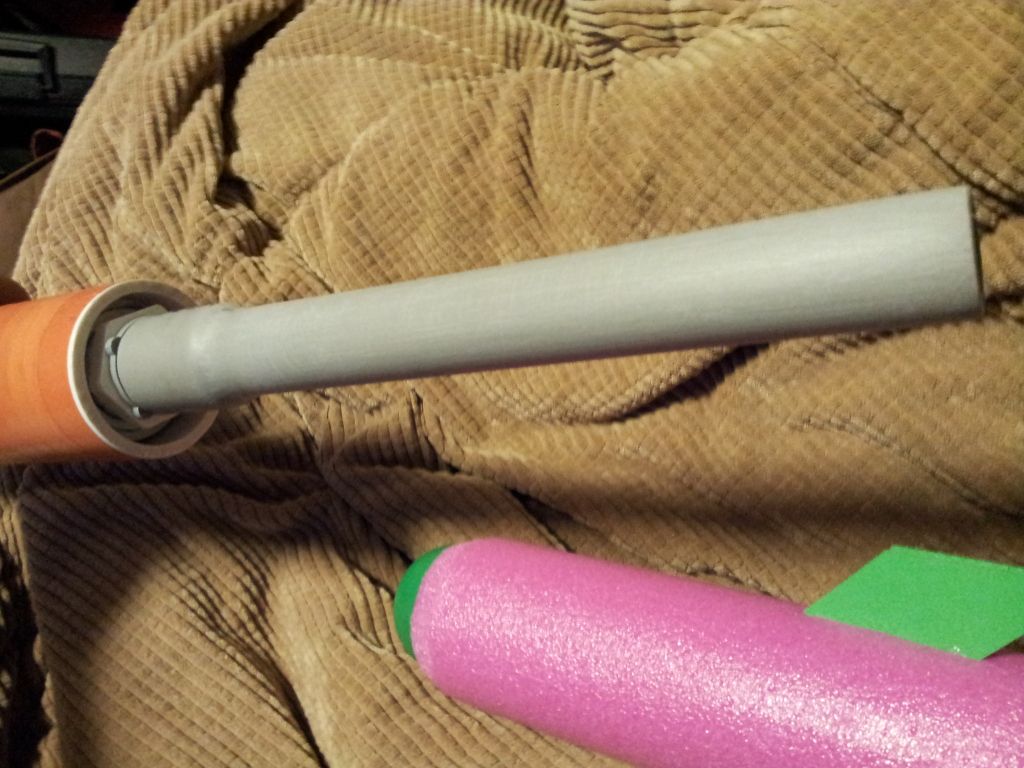

Rocket barrel material (I used Venom's "defective" .75" PVC)

~.75" ball bearing

Check valve

.5" of half inch copper tubing.

Cost: ~$35. (This is an estimate, as I largely build the blaster from scraps and on-hand parts...I spent $9 to get a few additional parts, most of which was a chunk of 2" PVC. My apologies if I missed a part or two in this list. I rounded high, at any rate.)

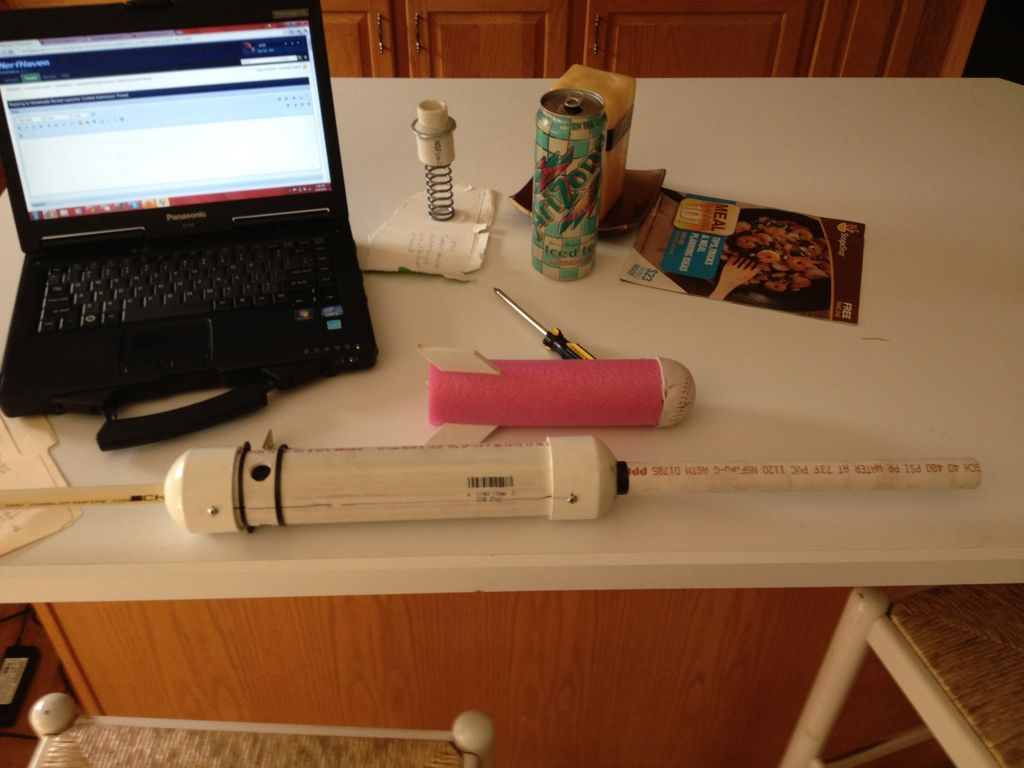

Description:All around, this is pretty much a bow similar to the original SNAP-7 bow I posted (the big one, not the little one), except that the plunger tube is based off of 2" PVC with a 1.25" endcap plunger head. (The bow arm assembly is actually literally from that blaster, as I reclaimed those parts.) A 1.25" tee seats nicely inside 2" PVC with some tape to pad it out. The bushing for the end of the plunger tube is built into the 1.25" tee: 1.25" tee + 1.25" PVC + .75" coupler wrapped in tape, shoved in place. I drilled a 1" hole in the other side of the tee and filed it out slightly to allow .75" PVC to shove through, which then seated into the .75" coupler at the other side of the tee.

The plunger is essentially a SNAP-1 plungerhead: two endcaps with a chunk of PVC holding them together, a rubber washer bolted to the front, then the CPVC cotter pinned to it.

The FlipFire valve is a .75" tee with a large ball bearing trapped inside. The stubs of PVC used to connect the elbows serve as the valve seats: they must be cut flat and smooth. Extra credit for beveling the edges or glueing in an o-ring, but I haven't found it to be necessary.

The 2" plunger is big. I mean, it's BIG. As such, plunger suck is a major problem. So, I installed a check valve, and installed a small antisuck mechanism in the wye: a small ring of .5" copper slides snugly in the wye, allows the next dart to feed, and keeps the dart from sucking backwards upon draw.

Also, SpeedHoles are

vital, due to the huge air draw. (The hole in the back of the plunger tube are 1" in diameter.

Ranges:Ranges are currently in a state of tweak, as barrel length needs to be adjusted.

Ranges:Ranges are currently in a state of tweak, as barrel length needs to be adjusted. Darts:

It's currently firing about 110' feet with a 19" barrel. Crazy big. However, there's still enough airflow that I'm still getting double shots. (The barrel was longer, but didn't shoot well).

Rockets:

Rockets are firing 46' (measured). The amusing thing is that the bow arms don't provide quite enough "oomph" to fire the rocket with range: it goes about 15 feet that way. I get best results by treating it like a ramrocket and manually pushing the plunger forward. Whether this is a function of my bowarms or plunger length is still up for question. It's possible that the blaster would do better with a narrower, faster plunger, rather than monstrous air volume.

It's also worth noting that the draw isn't too hard. I could probably increase power by shprtening the bow arms and making a harder pull.

8-12-12 EditTurns out part of the range and power issues I was having was due to my rubber washer: too big, and causing too much friction. I replaced it with the one I used on the Big SNAP, and had a gain of 5' on the bow powered rocket fire (so it's shooting about 20' by bow now).

For science, I tried removing the arms, and using it just as a ramrocket/HAMP style blaster. The barrel, as you might expect, wobbled all over the place, making it wildly inaccurate. The bow arms are unwieldy (yes, it's a 6' longbow), but it adds accuracy.

Stuff to fix:Obviously, it'd be nice to make rockets fire futher by bow power.

My plunger currently overdraws into the speed holes, so the rubber washer gets caught. Fixed with a 1" section of .75" PVC on the plunger rod. Once again, not elegant, but easy.

Screwing down the rest of the PVC joints so nothing wiggles.

Gooping the front 1.25" tee would be nice, but my seal is already pretty decent with duct tape and screws.

The elegant way to attach the check valve would have been to use a cross directly in front of the plunger tube, but I was all out of elegant. As such, I used another tee.

Every so often, the rocket will poop out about three feet while firing darts. This is probably from shaking the bow too much while firing, and breaking the bearing seal. This could be fixed by beveling the inner edge of the PVC inside the tee, to give the bearing a larger surface to seat against.

Overall, this is something I would use to rush the core in a rounds of DTC...spam a hopper of darts, then shoot a rocket when I'm within 40'. My goal was to get the rocket to fly over 40' (quite far enough for a round of DTC), so I'm quite pleased with the results.

Edited by Carbon, 19 April 2015 - 04:30 PM.

Hello. I am Indigo of the Rainbow Clan. You Nerfed my father. Prepare to die.