To solve this problem, in the past people have added craft foam, O-rings, etc, in an effort to increase the air seal. None of these work well - or if they do, don't last very long. This specific aspect has been a design challenge for many excellent modders over the years.

I came up with these two mods after my first removable cylinder Maverick -- I wanted better ranges, and with painted cylinders, the rotation was weak due to friction. I had of course seen and tried the "trigger spring relocation" mod (where you move the trigger spring to another post), but found this to be weak - and it would also bend the spring. I wanted a better seal, and stronger rotation.

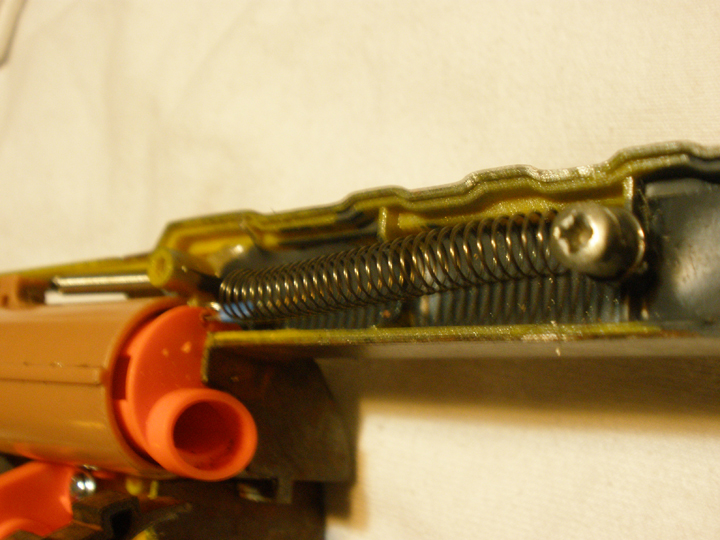

Solution 1 - Cylinder Rotation: add another spring IN-LINE with the clutch mechanism. It was so simple, I couldn't believe I hadn't thought of it sooner. The pic is fairly self-explanatory; Hand drill a small hole in the clutch mount, creating a small "cup" or hole at the bottom for the screw to seat into, and add a screw and extra spring. Attach the spring to the trigger, and leave the original spring in place. Bam! Double powered spring - no more rotation problems. (and no bent weak spring)

Solution 2: Improve nozzle seal to cylinder:

So like I mentioned I was making removable cylinder Mavericks and had the "extra" Mavericks for parts. The first time I did this mod, I used the slider spring from one of the extras -- later I bought a box of mixed springs from Ace hardware and used these instead. You can use a slider spring, or any skinny spring that is not too strong.

Again, the following pic is fairly self-explanatory - it's a nozzle spring I added to the Maverick to keep the nozzle pulled forward against the cylinder at all times, increasing the air seal. It is hidden in the upper support arm of the Maverick, and doesn't exert much force -- just enough to improve the seal. The pic is fairly self explanatory on the installation. Drill a hole in the nozzle body, add a spring to the post, carve out some plastic in between to keep it from rubbing.

Be careful drilling the hole in the nozzle body - I use an exacto knife. I have never gone through the plastic to the internal chamber in dozens of applications, but there isn't much plastic to work with, so be careful - less is more.

With the extra trigger spring, the added friction of the nozzle against the cylinder is a non-issue. No rotation or timing problems. The extra trigger spring works great for painted Mavs too - which seem to have some increased friction due to painted parts.

Using the above mods along with air tight barrels and increased spring compression + a bigger O-ring or Teflon tape, you can get 55-60ft PTG with regular Whistlers. (Of course PVC and Stefans even better!)

Edited by Rommel_McDonald, 22 June 2012 - 04:42 PM.