Overview - The blaster is now named the L-Shot (Lambda-Shot). It is a bolt-action rifle that accepts N-Strike mags. It is best described as a blend of the +Bow and Longshot.

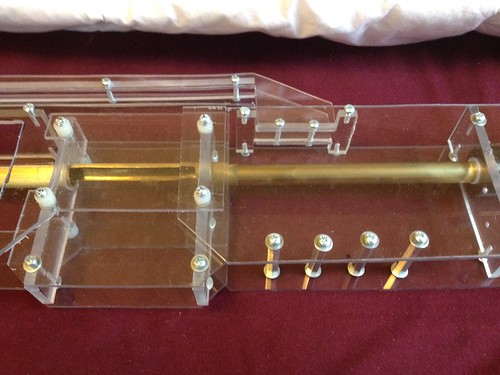

It all started with this, the L-Shot Prototype:

Here's a youtube video where I explain how it works. The basic operation is the same between the prototype and rev 1, so most of the information is in this video.

I then designed and built a better version, L-Shot Revision 1 (on the left):

Here's the youtube video about the changes:

http://www.youtube.com/watch?v=9wovA97NgBY

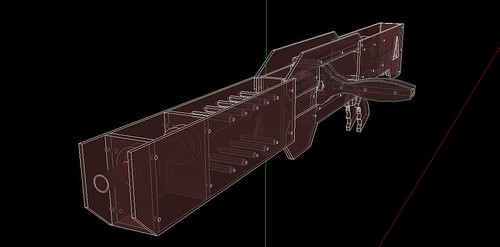

Model and Templates:

Meaker VI generously made the following 3d model and printable templates:

12" x 12" pdf: http://dl.dropbox.co...4889/LAMBDA.pdf

8 1/2" x 11" (will have to line them up): http://dl.dropbox.co...LAMBDA_8511.pdf

Google Sketchup: http://dl.dropbox.co...64889/HMLS3.skp

Parts List:

Stuff I got from McMaster:

8574K26 2 Each Impact-resistant Polycarbonate Sheet, 1/8" Thick, 12" X 12", Clear

8574K28 1 Each Impact-resistant Polycarbonate Sheet, 1/4" Thick, 12" X 12", Clear

8585K431 1 Ft. Impact-resistant Polycarbonate Round Tube, 1-1/2" Od, 1-3/8" Id, 1' Length, Clear

8585K631 1 Ft. Impact-resistant Polycarbonate Round Tube, 1-1/4" Od, 1-1/8" Id, Clear, 1' Length

91780A337 10 Each Aluminum Female Threaded Hex Standoff, 1/4" Hex, 1-1/2" Length, 6-32 Screw Size

90272A146 1 Pack Zinc-pltd Stl Pan Head Phillips Machine Screw, 6-32 Thread, 3/8" Length

90272A148 1 Pack Zinc-pltd Stl Pan Head Phillips Machine Screw, 6-32 Thread, 1/2" Length

6435K54 2 Each One-piece Clamp-on Shaft Collar, Black-oxide Steel, 9/16" Bore, 1-5/16" Od, 7/16"w

90131A104 1 Pack Abrasion-resistant Reinforced Rubber Washer, 1/2" Screw Size, 1-3/8" Od, 1/8" Thick

9637K26 5 Pack Continuous-Length Compression Spring Spring-Tempered Steel, 11" L, .844" OD, .08" Wire

8538K18 5 Ft. Nylon 6/6 Rod 1/2" Diameter

9562K46 1 Each Stretch-fit Rotary-shaft Ring Seal, 1" Shaft Diameter, 0.95" To 1.07" Shaft Diameter

Stuff you can get from your hardware store in smaller quantities:

90272A151 1 Pack Zinc-pltd Stl Pan Head Phillips Machine Screw, 6-32 Thread, 3/4" Length (I used 5 of these).

91090A109 100 Pack Zinc-Plated Steel Large-Diameter Flat Washer 1/4" Screw Size, 1-1/4" OD, .04"-.06" Thick(I used 2, for my plunger head)

90126A509 100 Pack Zinc-Plated Steel Type A SAE Flat Washer NO. 6 Screw Size, 3/8" OD, .03"-.07" Thick (I used 1 or 2, for my plunger rod)

90295A080 100 Pack Nylon 6/6 General Purpose Flat Washer Off-White, NO. 6 Screw Sz, .32" OD, .02"-.04" Thk (I used 2, for the catch)

Stuff I got from my local hardware store (didn't find 17/32 brass on McMaster, only 9/16" and 1/2" -- probably there somewhere though):

9/16" Brass tube, 1 foot - Dart pusher, plus misc. brass

17/32" Brass tube, 1 foot - Barrel

1/2" Brass tube, 1 foot - Breech

Stuff I don't know where you would find, but probably have in your house already:

2 small springs, one for the trigger, and one for the catch. These fall out of nerf blasters if you take them apart. Pretty sure mine were from various Longshot locks.

Coarse Threaded screw, 1 1/4" (wood screw?) - I had these lying around my house. Used for plunger rod ends, because 6/32 thread ripped out of the holes.

Writeup Part 1 (ignore the catch assembly -- it has since changed):

http://nerfhaven.com...ndpost&p=311529

Writeup Part 2 (the final handle assembly -- see below):

http://nerfhaven.com...ndpost&p=311678

These two changes came after the two writeup parts were posted. The updated parts are in the printable templates:

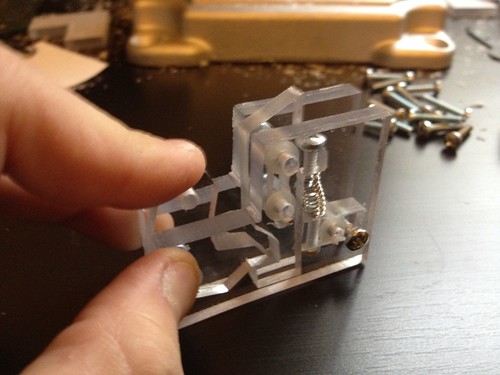

Revised Catch:

http://nerfhaven.com...ndpost&p=311746

Revised Priming Handle:

http://nerfhaven.com...ndpost&p=312223

I will continue to keep important information indexed in this post.

-----Original Post lives on below-----

Video here:

FNG reporting. This is my homemade rifle. My goals were to produce something that accepted Nerf mags, shot streamlines, had 100'+ range, was easily serviceable, and didn't look like a plumbing project gone awry.

Some notes:

Construction is out of polycarbonate. The sides are 1/8", with 1/4" pieces for internal bits and the grip. It used a bit more polycarbonate as a plusbow would have: three pieces of 12"x12" 1/8, and two pieces of 12"x12" 1/4. (I'm working on a second version that will use two sheets of 1/8 and one sheet of 1/4).

As you'll see in the video, the plunger tube and outer brass breech are connected together as a unit, operated by the priming handle. To reduce the 1 1/2" polycarbonate air chamber down to 9/16, I made 3 polycarbonate rings with a hole saw (just under 1 3/8 outer diameter, 9/16 hole), and used two 1 3/8" rubber washers to make it air tight (ring, washer, ring, washer, ring). The rubber washers stretch over the brass nicely. Screws hold it all together -- the middle ring has set screws to hold the brass in place, the outer rings are held in place with screws through the air chamber. I used a polycarbonate rib inside the 9/16 to push the dart *just* into the 17/32 barrel.

The breech itself is about as simple as I could make it. Just a 3 1/4" long section chopped out of the 9/16 brass, half the diameter. I left 1" of intact brass at the end that always stays around the 17/32 barrel. Since the whole thing travels about 6 inches when you prime the gun, it has to travel really far forward over the barrel. The barrel attachment is very near the nose of the gun. The barrel is held in place with shaft collars. McMaster part number would be 6435K54.

It uses the original plusbow plunger head. I will be changing it to Split's plunger head in the second version.

It met all of my goals except one: firing stock streamlines. The [k26] has way too much power for them. Ideally, they'd fly far, but the reality was they'd tumble through the air with a kicking spiral. To fix this, I hot-glued the tips of my darts. No idea who came up with the idea, but it isn't mine. Hot glued streamlines fly really far and don't tumble. However, they do not fly all that straight.

Things I like:

Fires at least 60 paces.

I think it looks cool.

At point blank range, a dart will go through both sides of an empty cereal box, so that's awesome.

My friends are terrified of it.

Things I don't like about it:

It's heavy.

It's hard to prime.

Not accurate beyond medium range.

It was my first time using a scroll saw, so up close it is pretty ugly.

Should have built it to fire Stefans.

Let me know if you want a writeup or some pictures.

Edited by dapperrogue, 07 March 2012 - 05:03 PM.