A lot of these items can be substituted for other stuff, but this is how I did it.

Wire Cutters

Hot Glue + Hot Glue Gun

Tape

GOOP

Drill with drill bits, 1/16" for paperclip or same diameter as your nail (see below)

Sandpaper or file

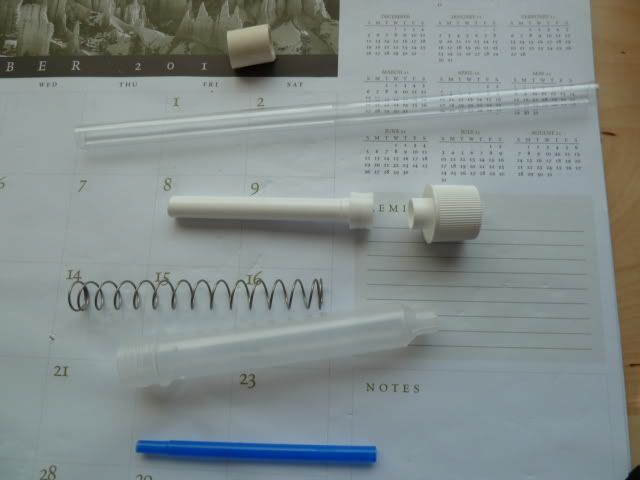

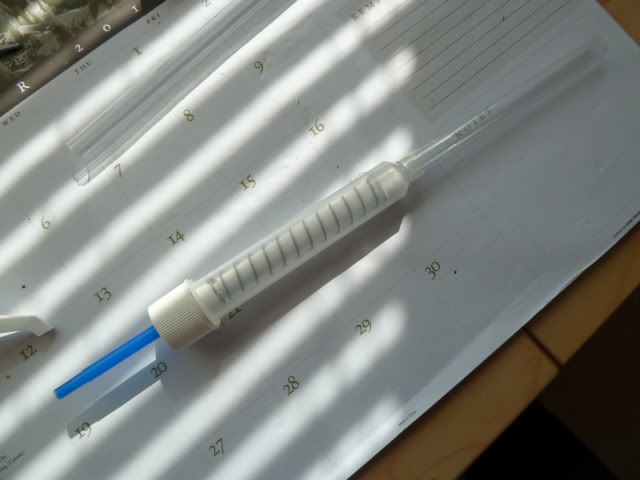

Hand pump from TAP Plastics or similar. Gotta have a strong spring.

Handle Extension. Something that fits inside the hollow part of the hand pump. For me, this was a trash ballpoint pen.

Paper Clip (or thin nail)

Barrel:

PETG

OR

PVC Coupler + 1" stub of PVC and barrel of choice

So I found some hand pumps at TAP Plastics for sale: $1 each.

http://www.tapplasti...ct.php?pid=174

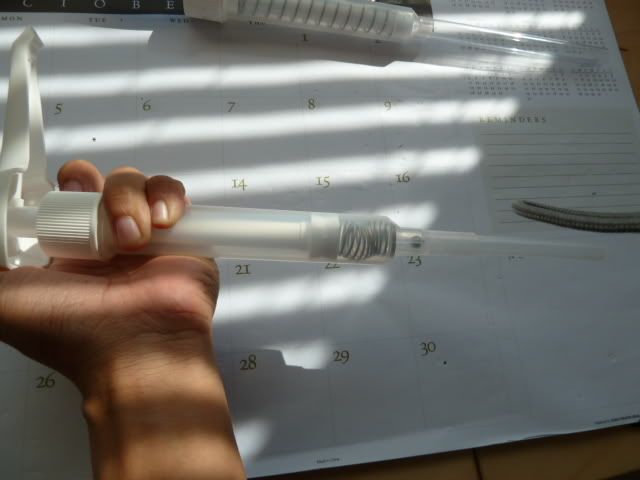

It had a spring, really good airseal, and a handle. Pretty much all it needed to become a foam-flinging device was moving the spring location. And that was the problem - the handle was fused to the plunger rod.

Sticking the entire thing in boiling water would remove the parts, most likely, but there's still the problem of achieving maximum efficiency. The handle doesn't go all the way in when stock.

There's a weird tab in the cap that prevents it from going further in, even without the spring.

So I made a new handle.

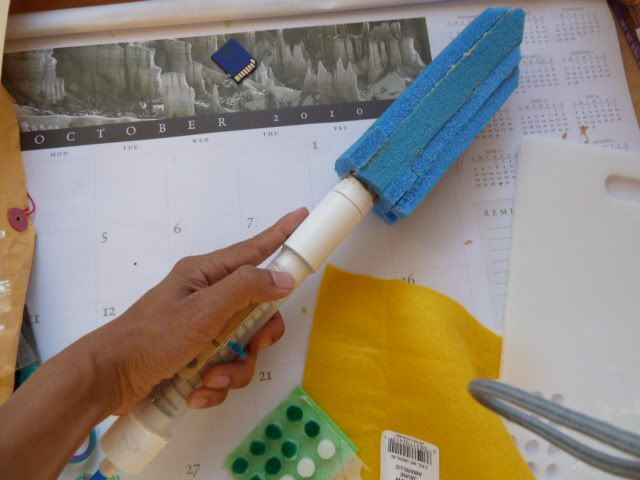

Snip off the tip of the plunger tube, we don't need it. The ball bearing will fall out. Also remove the large pump part of the plunger.

Seal the plunger with hot glue. It was designed to let air through, we don't want that.

Prepare your handle extension ballpoint pen. Wrap it in tape until it fits into the handle snugly. Push it about 1/2" in.

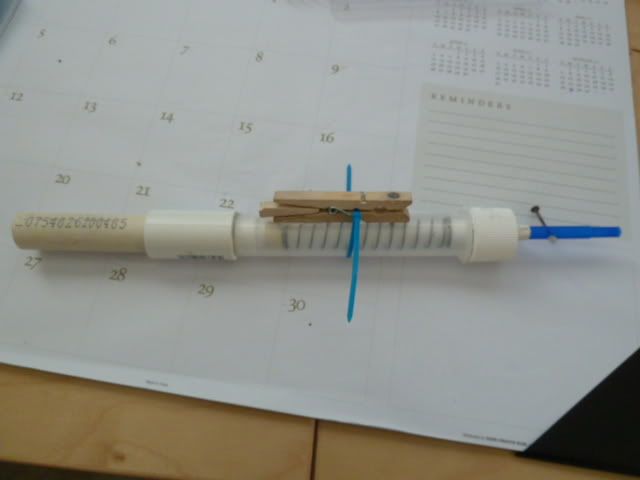

Drill through your plunger/pen/tape with the 1/16" bit.

Then pull the pen out, apply GOOP, and stick it back in. Lock it in place with the help of GOOP + paperclip.

Remove any metal or plastic that's sticking out with a file or sandpaper. The cap has very little gap, and if anything's poking out it'll get stuck.

Stick the spring back on, lube it up with anything (No washer, so petroleum jelly is a go).

If it's PETG, your journey ends here. TAP Plastics pumps are just the right size for PETG to fit around.

Otherwise, take a PVC coupler, hammer some PVC in that, and hot glue/goop it in.

I'm considering adding a cross-piece to the handle so it's easier to prime. Maybe a duct tape-wrapped nail.

Added that PVC coupler. Just stuck a lot of hot glue on it... works with any feed-assist hopper, which is what I'd expect from something with power like a modded NF. Gets more consistent ranges too. I was getting misfires with the PETG.

Still a work in progress, fixed the materials list. Working on making a trigger system...

If you can't order springs off McMaster, these are good viable springs. Not good for a primary, but for integrations and small sidearms, yes.

Edited by Darksircam, 08 June 2011 - 12:12 AM.