The Basic Design

I got the inspiration for this while looking at Boltsniper's semi-auto prototype. I did not notice until after the fact that it works similarly to a paintball marker.

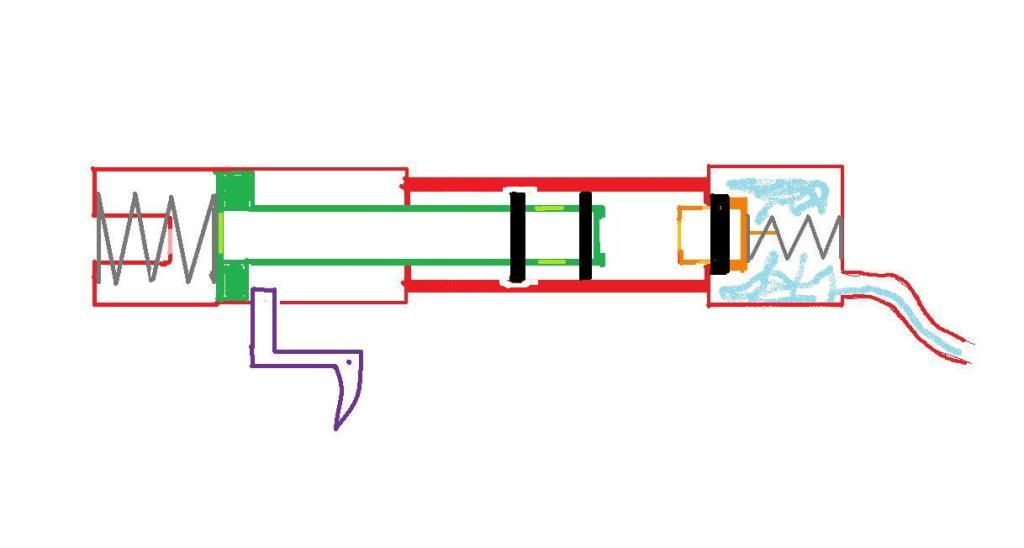

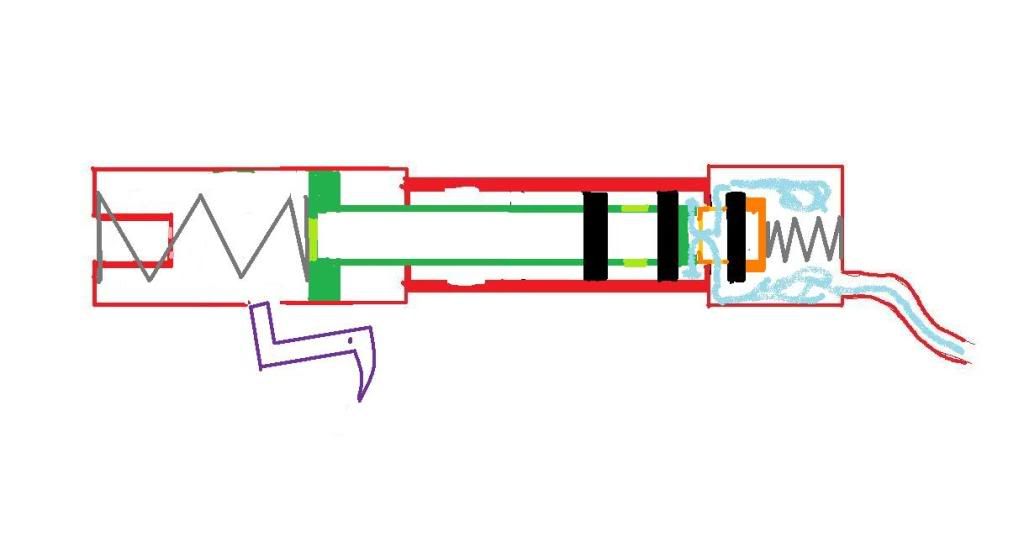

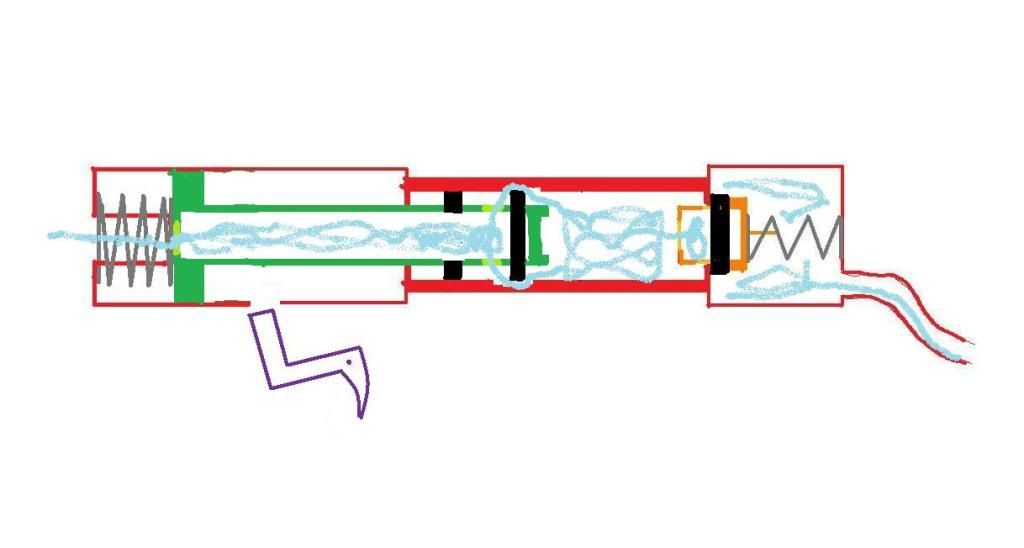

*These rather shabby paint diagrams represent the cross-section of tubes. Lighter shades represent holes in the wall of the tube. Black lines represent o-rings.

1.) The trigger holds the piston in a partially forward position. The airtank at the back is sealed off by a small valve.

2.) The trigger is depressed, allowing the piston to be propelled backwards by a spring. The piston hits the valve, forcing it open.

3.) Air is released from inside the tank, forcing the piston forward. The piston seals with the air outlet (barrel) and also opens vents, which allow air to flow past the first o-ring, into the piston, and through the outlet. After the air is released, the piston is pushed backwards by the spring, where it is either stopped by the trigger or continues to cycle.

This topic is locked

This topic is locked