What you will need:

- PETG from OMC (Length depends on what blaster you plan on using it in)

- 1/2" Sch. 40 PVC (Same length as your PETG)

- 2" of 5/8" brass

- A 1/2" PVC coupler

- Adhesive of your choice (I used good ol' Goop and Fishin' glue)

- Electrical tape

- Pipe cutters

- A hobby knife

- A rotary tool

- A cutting wheel for said rotary tool, strong enough to cut brass

- A 5/8" diameter grinding wheel, also for the rotary tool

- A rubber mallet

- Sandpaper (To make your cuts smooth)

- Needlenose pliers )Optional, but extremely useful)

- Measuring tape

- Sharpie to mark where you plan on cutting

Measure 1.5" down from one end of your PVC pipe. Take your Sharpie and put a dot on the 1.5" mark. From that point, measure out 2" or so (Slightly longer than your Stefans). Draw a line along the 2" and trace out the rest of the half-pipe:

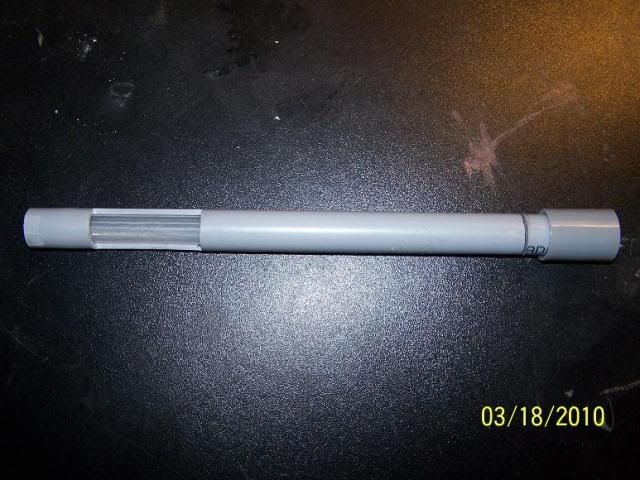

Bust out your rotary tool (Or what ever you use to cut) and cut along the lines. Try to clean it up with a hobby knife and sandpaper:

Now, take that piece of 5/8" brass and measure 1.5". Mark it down and then put another dot about 1/2" ahead of it:

Take your pipe cutters and put two or three tightening rings in the 1/5" piece. Be careful, and check the fit on the PETG often. You want it to have a good seal, but you also want to easily pull it out as well. Once you're done, put a very light ring around the 1/2" long piece:

Cut where you marked:

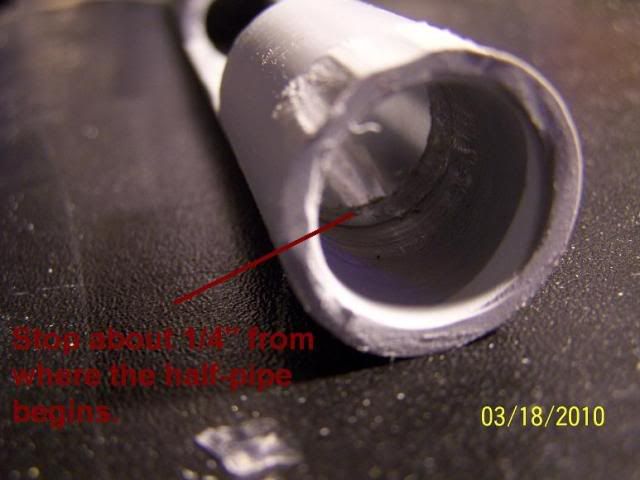

Take the 5/8" grinding/sanding wheel and sand out the PVC ALMOST up to the half-pipe. Be very careful and try not to make the hole too wide:

Take your rubber mallet and hammer it in until the brass is almost flush with the PVC. Be sure to use a rubber mallet, or else the brass will deform when you hammer it:

If you have made it this far, awesomesauce work. Now we're going to go to the other side of your PVC pipe. Cut about 2" off that end with your pipecutters:

Get your mallet again and hammer the PVC completely through the PVC coupler. An alternative would be to just sand out the ring in the middle of the coupler, but I was lazy:

Take your e-tape and wrap it around one end of your PETG. Apply Goop and put your PVC+coupler over it:

Leave it to dry.

Once again, go to the side opposite the half-pipe. This time, use your 5/8" wheel and sand about 1/4" in:

Place the 1/2" long piece of 5/8" brass in:

Get your mallet and hammer it flush with the PVC. This will keep the PETG barrel from flying out when the breech is opened:

Take your two parts and put them together:

Edited by deaddumpster, 18 March 2010 - 03:22 PM.