I chose a hornet because the trigger location can be anywhere, I got some internals cheap, and because they can be more reliable/durable than pin release tanks; that's if you get good ones.

The biggest problem in this was I wanted it to be clean, so that means no external tubing, internal pump, no excessive shell cutting, and it should look nice overall.

Lets get to work!

Materials

2 hornet tanks

3/16 wye 53055K154

3/16 to 1/8 reducer 53055K126

1/8 tubing coupler barbed

1/8 id 1/4 od vinyl tubing

1/4 id 3/8 od (I think) vinyl tubing

1/8 vinyl tubing coupler Barbed not push to connect

Spiderman dartag pump (SdtgP)

#10 screw size nylon spacers 3/8 od

two 6in sections of petg/ airgun barrel

various 6/32 screws

1/2 thick polycarb (not a lot)

*Important-The majority of the cuts in the shell SHOULD NOT be made with a dremel. Take your time use a hobby knife, file, or small hacksaw. The dremel can make uneven/ rough cuts, and you dont want it cutting tubing.

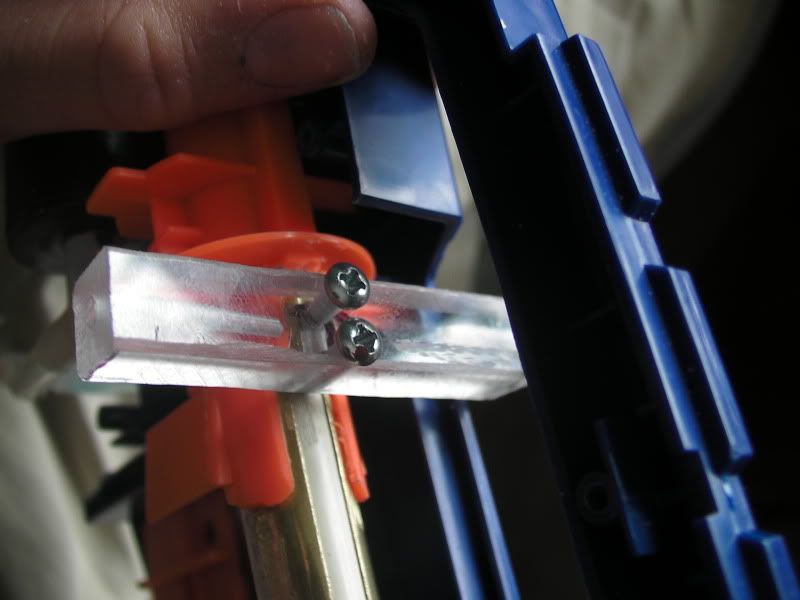

Start off by making your breech. It can not use the boltsled because it will get in the way of your pump.

A good one to use is my breech seen here. Make sure you read all the updates in that thread, and use two bolts in the bolt not one.

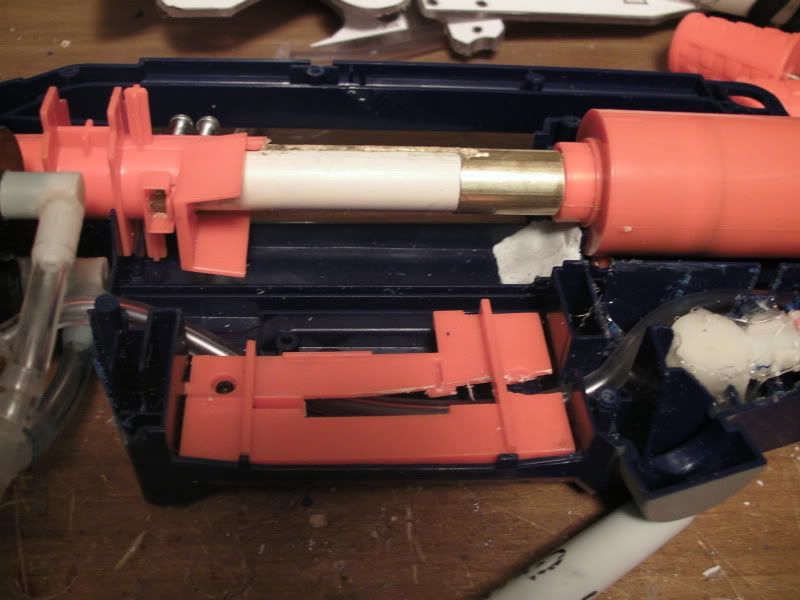

Once your breech is done reinforce the shell. I did this to help contain the awesome power of a [k26], and I don't want it breaking.

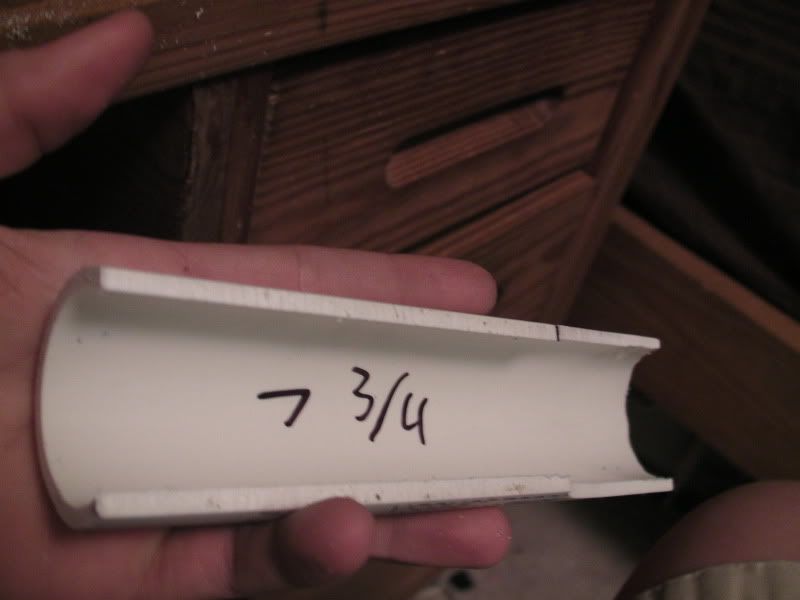

Cut down your SdtgP 11/16

Drill a 11/64 hole in the pump or wide enough for the ls bolt to fit through.

The length from the end is not specified it is the right length to get the largest stroke.

Do some shell cutting like the pictures.

This is how the pump should fit in.

Notice how the tubing comes from underneath the trigger, and goes into where the stock used to slide.

At the end of the stock tubing is where you add your 1/8 tubing coupler.

Take a hornet blast button add a pin like Boom13

Also gooop in the 1/4 od vinyl tubing in some 1/4 id vinyl tubing which should be gooped in the blast button.

Time for more shell cutting.

That's how it should end up fitting.

Edited by louiec3, 28 February 2010 - 12:21 AM.