Posted 05 January 2010 - 11:32 PM

Edited by dizzyduck, 19 January 2010 - 10:49 AM.

Posted 05 January 2010 - 11:43 PM

yeah I'm that guy who made that cool thing with the cool paint.

Posted 05 January 2010 - 11:49 PM

Posted 05 January 2010 - 11:49 PM

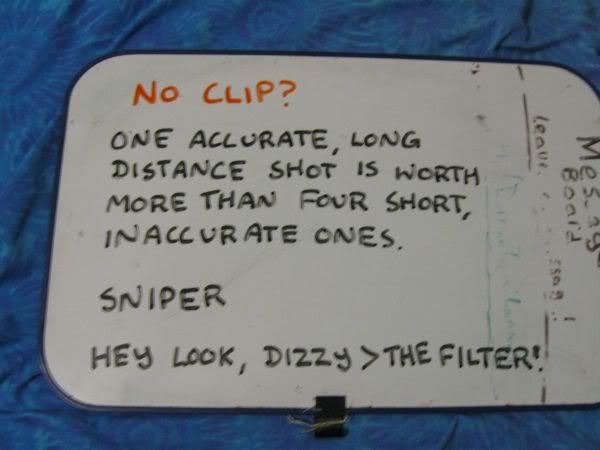

I'm not saying "WHERES THE PAINTJOB, DIZ", but I am saying I'd like a few things to be bumped up to add to it. Even just some flat black on the stock and a slightly better constructed plunger rod handle would really make this thing look as intimidating as it really is.

Amazing work though man. What barrel length/material are you using?

How badly is the gun rattling when it's fired/how loud is it currently?

Posted 05 January 2010 - 11:51 PM

Posted 06 January 2010 - 12:27 AM

Posted 06 January 2010 - 03:04 AM

yeah I'm that guy who made that cool thing with the cool paint.

Posted 06 January 2010 - 10:21 AM

Alright. Do you think the loudness is something FBR or whatshisfaces modeling clay sound dampening could really help?

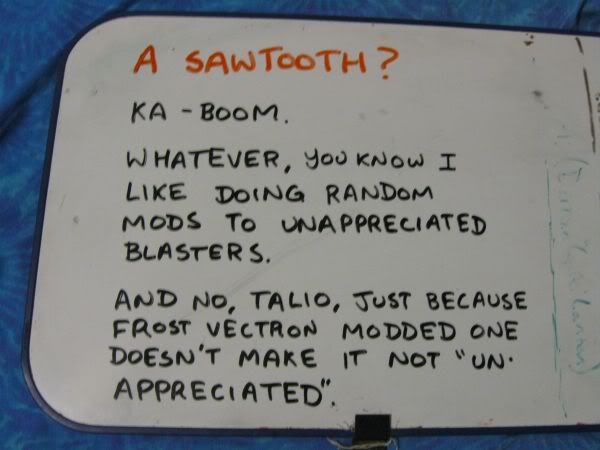

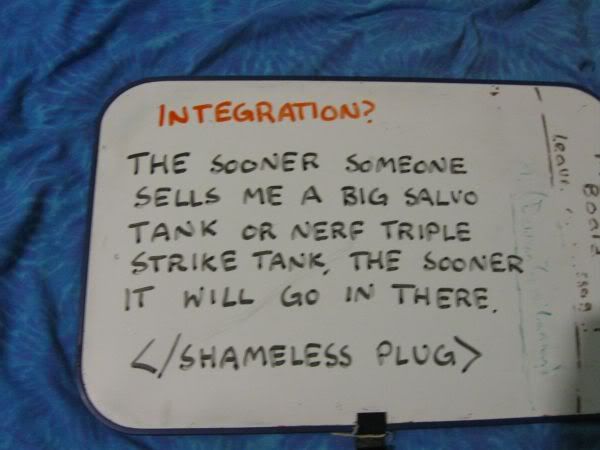

Speaking of integration, are you in need of the sawtooth scope/considering the sawtooths scope for the integration?

Back to to the matter of the handle, if you don't already have plans, Taking some lexan and putting in the over (when you're home alone for a long while so you can get rid of the smell haha), or a heat gun and bending is something you could definitely try.

Posted 06 January 2010 - 02:40 PM

yeah I'm that guy who made that cool thing with the cool paint.

Posted 06 January 2010 - 06:10 PM

Glad you put those rods to use! What method did you use to attach them together? They were only a foot long so...

Posted 06 January 2010 - 06:29 PM

Posted 07 January 2010 - 08:31 PM

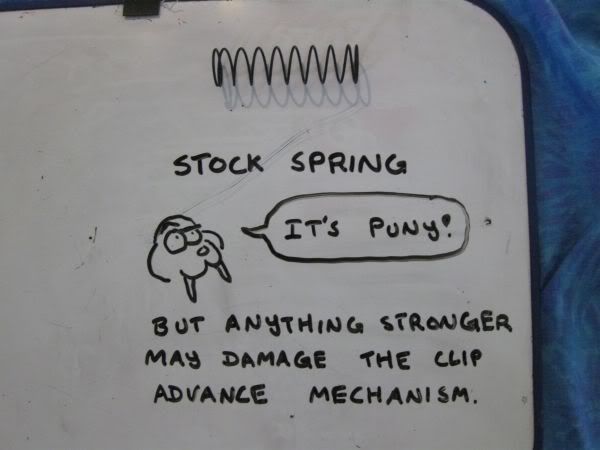

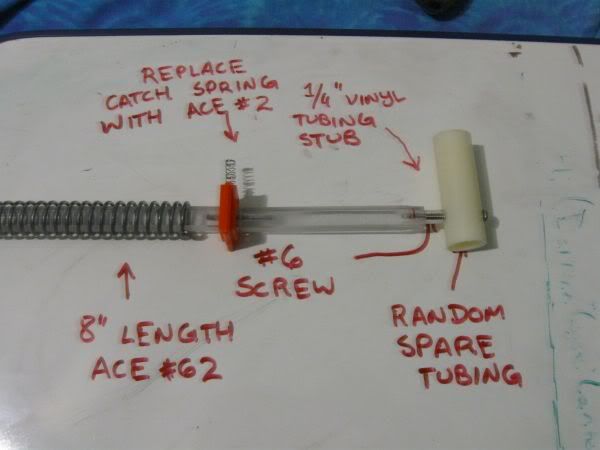

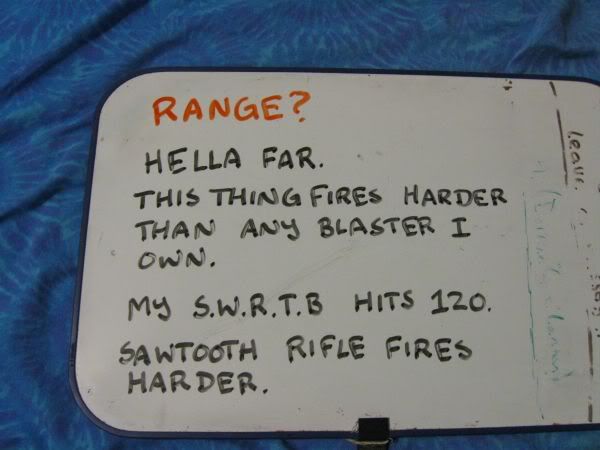

Anyways, I am not sure that you mentioned the type of spring that you used.

If you could just say what type it is and where you got it that would be very helpful.

Posted 07 January 2010 - 08:49 PM

"Too close for missiles, I'm switchin' to guns"

Posted 07 January 2010 - 09:33 PM

Edited by CA13, 07 January 2010 - 10:05 PM.

Posted 07 January 2010 - 11:43 PM

Dizzy, you should probably cut down the magazine shell, and cove the hole with the cuttings. Then you won't have a wonky front end to fool with!

Posted 08 January 2010 - 09:32 PM

Edited by A side of nerf, 08 January 2010 - 09:32 PM.

Posted 09 January 2010 - 12:01 PM

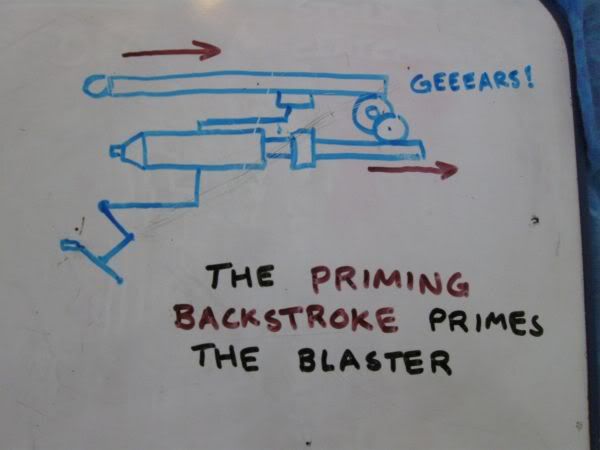

The shell of this blaster is also really cool which is why the new internals make it a good (function and looks) primary.

0 members, 1 guests, 0 anonymous users