When I began I realized this would make a potent nerf weapon so I decided to nerf it a bit and cut it down.

I modified the CAD plans and got to work on this awesome gun wondering if it would succeed or fail horribly.

I succeeded

I call it Dr. Frankenstein

Just to prove it is 100% compressed.

Well now I better tell you how to make one...

*If you have never machined with plastics, or sketched accurate pictures this is not a good place to start.

Print out some +bow templates. If you already have a +bow just print out what you need.

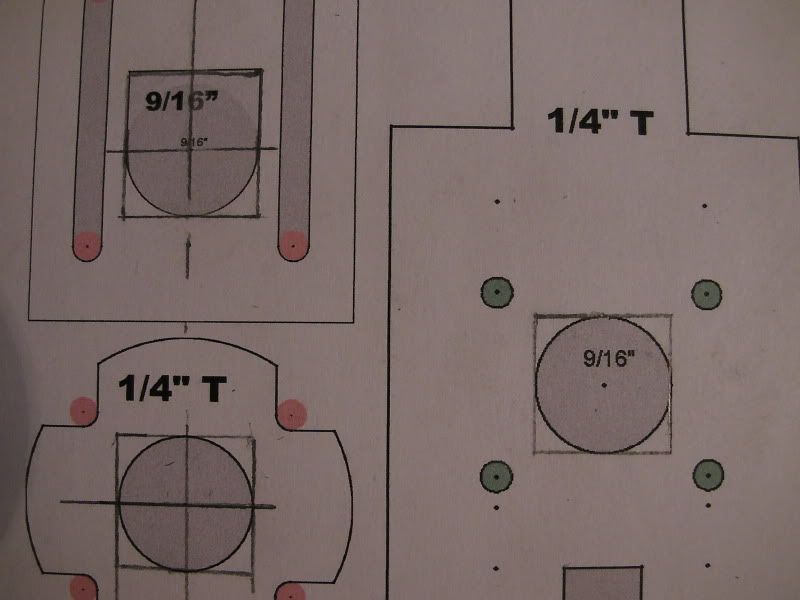

Start by sketching 9/16 squares around these pieces make sure the squares are not crooked or tilted.

Do not sketch a 91/6 square on the circle!

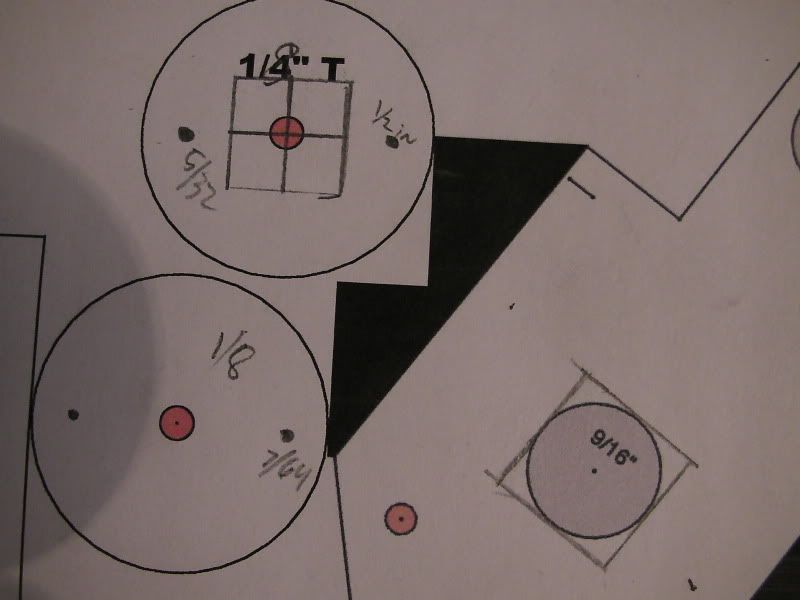

On one circle sketch a 1/2 square and on both mark two holes for drilling in the same spot on both circles

The circle with the square needs 5/32 holes and the circle without the square needs 7/64 (which you will tap)

Both circles are 1/8in polycarbonate.

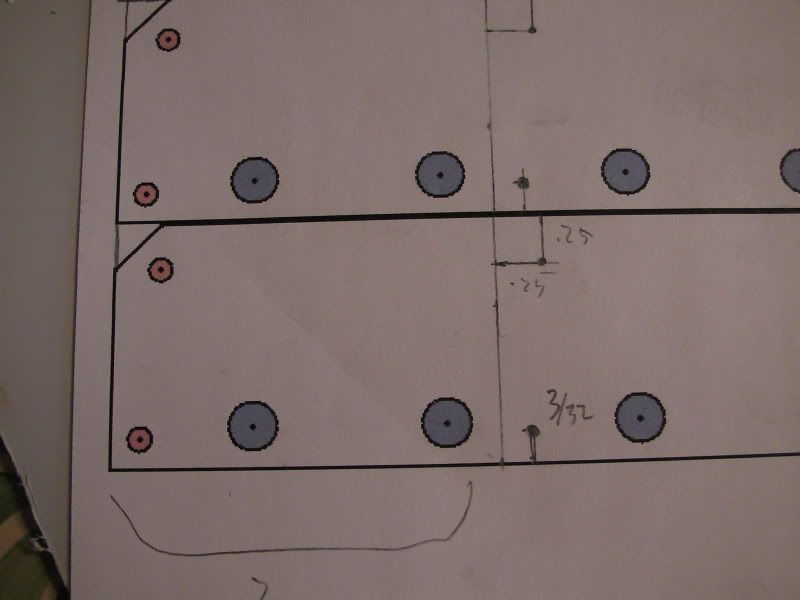

Next is easy just measure off two inches from the front and place those two holes in the same spot. I would leave the corner not rounded off because it might increase the durability of the piece.

Drill the proper size holes, and cut out your pieces.

Now grab some 1/2 thick polycarbonate and cut it to 11.6 and 1/2 wide. oh wait you might need a mcmaster number 1749K14

The vertical part of the notch is 3.1 away from the front of the plunger rod.

Take your two circles and put them together with 1/4in screws.

fit it onto your plunger rod and drill and tap the hole into the plunger rod.

Take your rubber skirt that you probably need a number for 9562K46(credits to split for finding this) and sandwich it between the front and back of your plunger head. Tighten a 1 1/4 screw down on it make sure it is very tight otherwise the skirt will move and you won't get a seal.

The finished product should look something like this...

Assemble the rest of the pieces like a normal +bow, but don't put the spring on yet.

just for comparrison old and new

Now cut your spring to a little more than9 and slide it on the plunger rod, but wait it won't fit bust out your dremel and sand down the edges of the plunger rod so the spring will fit.

with everything on the Dr. Frankenstein, that I forgot to mention because it is stupid if you forget it i.e. plunger handle, except for the plunger tube pull your plunger back until it catches if it doesn't trim a little off the spring repeat until it catches.

Once you finished everything put a healthy dose of silicone lubricant on the plunger and tube, and put everything together.

Now that you've read through all this you're probably waiting for ranges.

*Edit- I did range testing today with a 9in cpvc barrel (tight on my darts)

-with single bb 100-110ft

-cs stefans- 95-100ft

-1/4in slingshot 125-145ft

-Just for shits and giggles I shot a slingshot stefan at a 45 degree angle and picked it up 215ft away.

Edited by louiec3, 19 December 2009 - 12:46 PM.