Breech Questions

#1

Posted 14 May 2009 - 05:28 PM

So first off, let's say I'm working with a pull breech. How do I keep it do I can't pull the inside barrel material all the way out of the outside material?

And how do I make it so that the inside material can't twist and turn when jiggled around, in case you open the breech and the slot/opening isn't facing the way it's supposed to?

And thirdly, what advantages does a breech have over a speed-loader?

This has spiraled beyond uselessness into utterly stupidy.

Read it again until you figure it out.

#2

Posted 14 May 2009 - 05:56 PM

#3

Posted 14 May 2009 - 06:02 PM

I have a couple questions about the functioning of breeches. More importantly, how to get mine working well and how it should.

So first off, let's say I'm working with a pull breech. How do I keep it do I can't pull the inside barrel material all the way out of the outside material?

And how do I make it so that the inside material can't twist and turn when jiggled around, in case you open the breech and the slot/opening isn't facing the way it's supposed to?

And thirdly, what advantages does a breech have over a speed-loader?

I'll take this one.

A1 - to stop the moving part of your breech coming out, I would suggest glueing a section of the outer pipe to it as a block.

A2 - This should also stop any twisting, as long as the piece is big enough.

A3 - The advantage of these breeches is that a grav clip can be fitted relatively easily, increasing ROF.

Hope this helps.

EDIT - Shit, Fresh beat me to it.

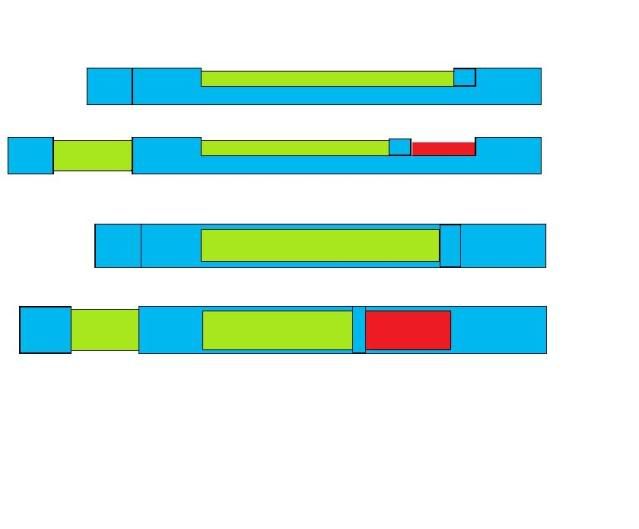

EDIT 2 - Pic to help

Green = Barrel material

Blue = Outer breech material

Red = Stefan Dart

Edited by BritNerfMogul, 19 June 2009 - 05:37 PM.

#4

Posted 14 May 2009 - 06:34 PM

Thanks for the good diagram Brit, that helps a lot.

This has spiraled beyond uselessness into utterly stupidy.

Read it again until you figure it out.

#5

Posted 14 May 2009 - 06:58 PM

Alright, thanks guys. Currently I'm working with PETG nested in SCH40 PVC, so it takes a wrap and a half to 2 wraps around the PETG of electrical tape to make the seal.

Thanks for the good diagram Brit, that helps a lot.

Not a problem. Good luck with your breech.

#6

Posted 14 May 2009 - 08:36 PM

Nerf Revolution

#7

Posted 14 May 2009 - 10:39 PM

This was a little hard to explain the way I wanted.

trans as shit because fuck you

#8

Posted 15 May 2009 - 09:32 AM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users