you need

1 3/4in to 1/2in pvc reducer

1 1/2in pvc Tee

1 #10/24x2.5 stainless steel screw

2 #10 nuts

1 #10 washer

1 3/8in faucet wahser ( i used a 1/2in and had to trim it down for the trigger to function.

1 piece of 1/2in cpvc

1 piece of 1/2in pvc

1 spring

hotglue

loctite

when buying pvc and cpvc make sure they easily telescope together... check through the pile in the stor sizes vary by batch and brand.

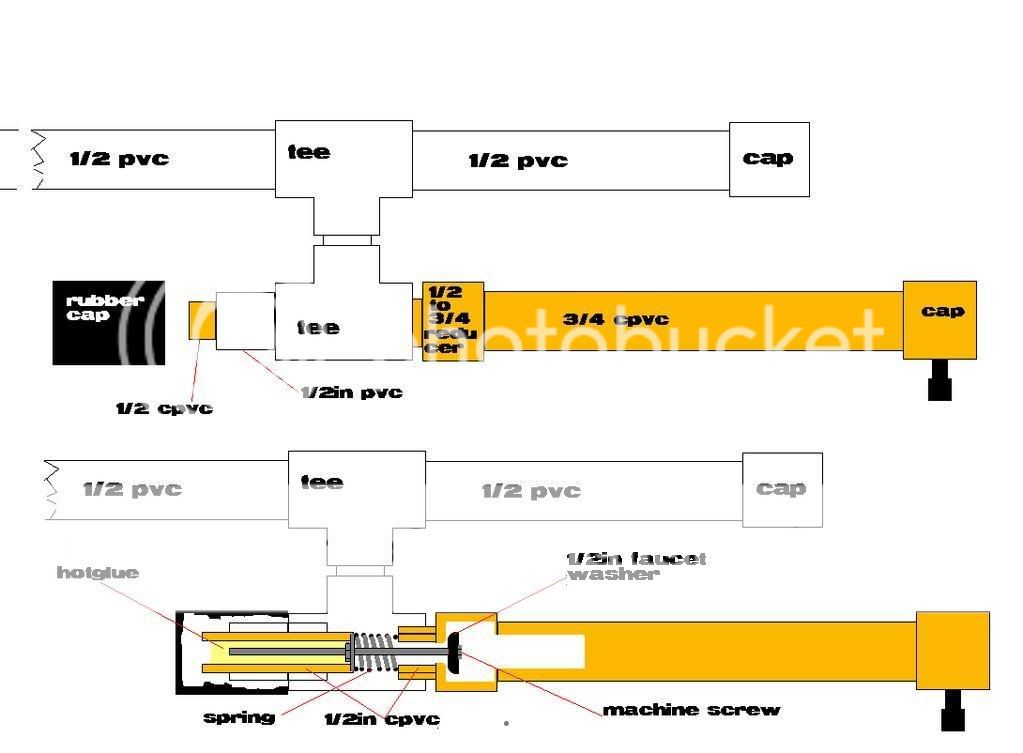

cut 1/2in long pieces of pvc and cpvc and put a piece of pvc into one end of the 1/2in pvc tee and the cpvc into the 1/2in side of the reducer.

make this

Modify spring like so

opening the final 2 coils so it will seat on the 1/2in cpvc inside the coupler

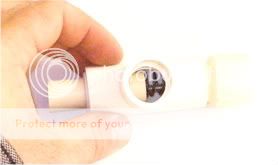

thread the screw into the washer and drop them into the big side of the cpvc coupler

put the spring on the other side and put a nut/washer/nut combination on carefully tightening until there is decent tension on the washer making a nice airtight seal. test by blowing through valve and opening wiht your finger... superglue or use threadlock to hold nut in place

glue a 2in piece of cpvc over the rest of the screw.

put the whole thing inside the Tee with the 1/2in cpvc and 1/2in pvc pieces sliding easily... I hotglued this part so it could be disassembled.

USE PVC CEMENT AND PRIMER on all air tank connections!!!!!

I do not have a permanent pressure pump yet.

Edited by Mr BadWrench, 19 January 2009 - 03:51 PM.