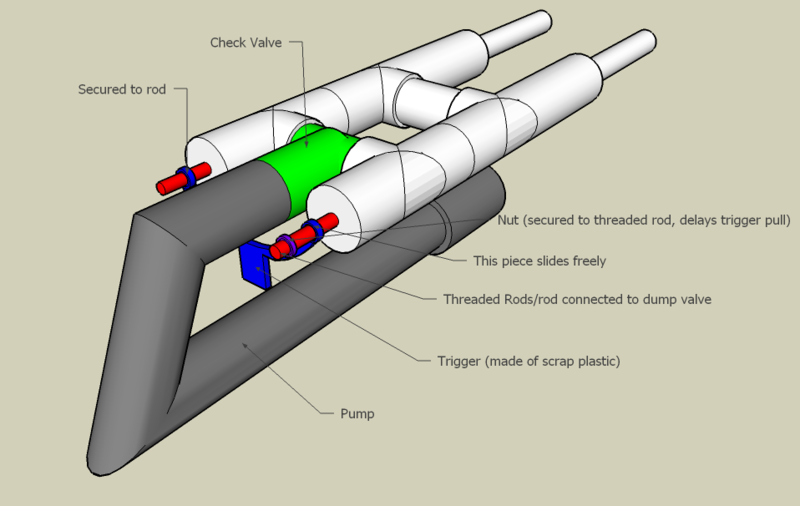

The image below outlines what I am trying to accomplish for the airtanks and trigger/valve system for this gun.

Basically, the pump will be housed either in the space below the barrels, or below the handgrip, depending on if I can get one to fit inside the shell or not. The pump hose will be split between the two air tanks, and a valve will be attached to each air tank with a two-stage trigger similar to what is already in place on the Double Shot. (If you are unfamiliar with the Double Shot, basically a partial pull will trigger one barrel, allowing a second pull to trigger the second, or a full pull to trigger both at once.)

Since I have not yet tackled any homemade projects yet, I would like any feedback about potential trouble spots with this design, as well as any ideas for something to serve as my air outlet at the end of the system. Basically, after the valve releases the air, it reaches the breech location, where the Double Shot's barrels break away for loading. I am currently considering using the existing outlets from the Double Shot, and just connecting my tubing to that with epoxy or plumber's goop, then using a foam gasket to get a good seal between the outlet and the barrels when they are engaged. (The barrels will be replaced with either nested brass or CPVC, allowing a shell-less rear-loading system that keeps the Double Shot's breakaway loading intact, without the annoying shell ejection.)

Also, the image shows the inlet from the pump to the tanks being on the opposite side from the outlets to the valves. Would it be too much stress on the endcap to have both the inlet and the outlet in the same endcap? That would reduce the amount of tubing required, and make it easier to get the whole assembly to fit into the shell.

Edited by Ambience 327, 27 August 2008 - 10:17 AM.