One thing I didn't like about the Titan is it's reload time. *20 pumps, insert dart in barrel, ramrod dart, pull trigger, repeat* was just getting annoying. Of course there's no easy way around the pumping, so I decided to make loading easier.

This is all VERY simple and can be done easily if you follow the instructions. I'm not sure if this has been done before, but I searched and couldn't find anything.

Materials:

- A Titan

- A Dremel

- A Hacksaw, sandpaper and a file if you do not have a Dremel

- An Exacto knife

- 1' or more of 9/16" brass

- 1' or more of 17/32" brass

- Glue of choice (I use Plumber's Goop)

- Hot glue gun (if you're planning on plugging the pump)

- A roll of E-tape

- 1' or more of 1/2" Sch. 40 PVC

- Safety glasses (you will be cutting PVC and brass, I would recommend it)

Okay, first remove the stock "barrel" (it should unscrew, if not cut it in half) and cut down about 1/4" of the threaded piece:

Bust out your Dremel and sand it out until it can fit 1/2" PVC well (PVC won't be in it, but you shall see):

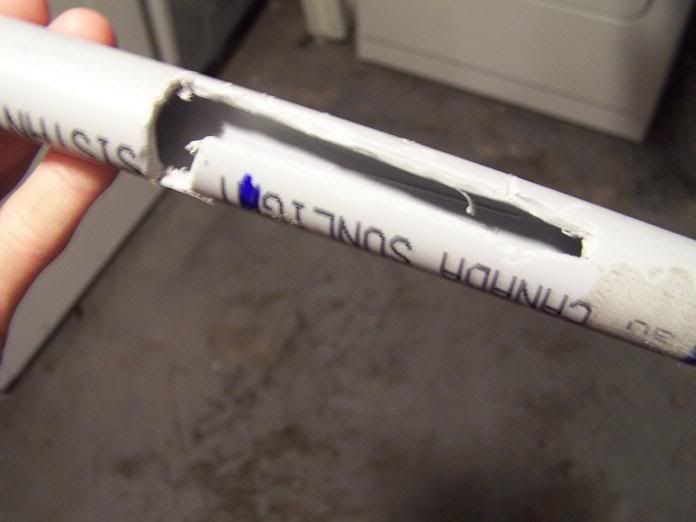

Take your 17/32" brass section and cut out a half-pipe about 1.5" from one of the ends. Wrap E-tape around said end until it fits snug into the threaded stub. Tightening rings might be useful too:

Now, find that piece of 1/2" PVC I mentioned in the materials list. Cut out a 3.5" section at one end, this will be the outer protective barrel of your Titan:

About 3" from the other end of the pipe, Dremel out a small strip so you can attach a dowel or something of the like to simplify the opening of the breech. Note that I cleaned it up and widened it slightly after this was taken:

Take your section of 9/16" brass and wrap E-tape around one end until it fits nicely into the PVC (No particular length, E-tape thickness varies). This isn't for sealing or gluing, just to keep it all centered in the PVC:

Put the 9/16" over the 17/32" so that the e-taped ends are on opposite sides. insert the new barrel in the PVC to see how well it looks/fits:

Remove it and pull out your Plumber's Goop. Put glue on the E-taped end of the 17/32" and insert it into the Titan barrel stub:

Let it all dry and then put the 9/16" brass over it. Fit on the PVC sheath and apply some strong glue to where it meets the Titan barrel stub (Goop might work, but just to be safe I added a bit of Crazy Glue so it would hold):

Now take a small piece of dowel or the like and sand down a curve on one end so it fits nicely on to the 9/16" brass:

Glue it on and check out your finished product. Reload time will increase and you can plug the pump if you want to (I did, but I just wanted power out of it). I hope you children weren't expecting much, combined time it took to do this was about an hour and a half.

Ranges are typical:

152'

154'

163'

169'

161'

153'

162'

168'

159'

163'

1604'

Average: 160.4'

Again, nothing special, just a fun little side project while I work on my latest killing machine. I sold this fucker to a friend about two weeks ago (it's not that new) for $50, so I'm happy I did it. I also got this Titan at Goodwill for $0.50, so it's well worth it.

Edited by deaddumpster, 07 August 2008 - 07:33 PM.