Posted 04 May 2008 - 09:28 PM

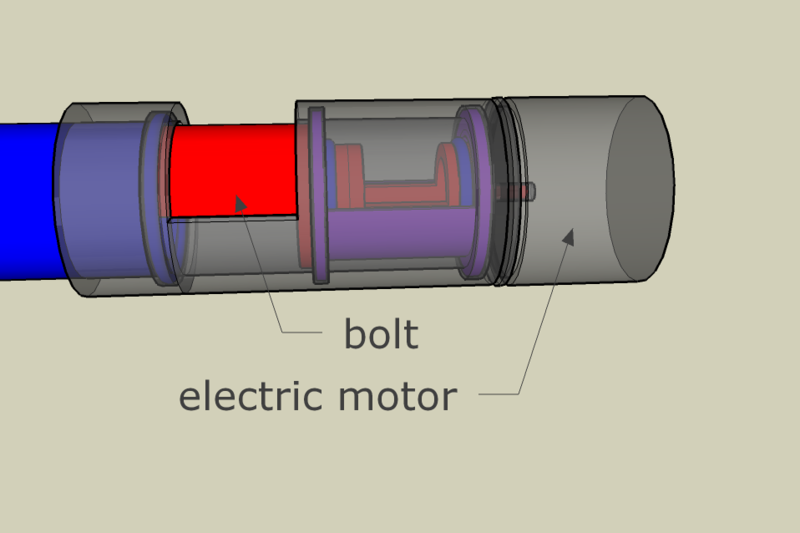

Any basic motor will turn a light piece of plastic if there's no resistance (including being well lubed). The radio shack motor will do. There is another problem though. Basic electric motors free spin. This means that once you stop putting power through to the motor, and it stops spinning, the momentum/un even weight of your "bolt" could just make it move again.

Also, if there will be a load on the "bolt"" (this is an incorrect term, but I know what you mean), then you will need either a higher torque motor or a gear head motor (which has has enough torque to spin no matter what basically). Gear head motors will also solve that free spinning problem, as they lock into place when they stop. Think of a power car window, since that's a typical application for them. However, these types of motors are usually large and less cost effective (if you know what I mean).

To vary speeds, change the voltage to the motor. To vary the voltage you could buy a variety pack of resistors and test them out to what you like, or you could buy an adjustable one. Be aware that Radio Shack stores mostly do not carry electronic pieces anymore, but there are some. If you do end up buying off of the internet, just use allelectronics.com . The shipping is constant no matter how much you buy, and the prices are great, and even better with bulk discounts.

Use a "momentary switch" also if you were wondering which to get.

/end semi-helpful rantish post.

Teehee.