#1

Posted 10 March 2008 - 08:22 PM

#2

Posted 10 March 2008 - 08:32 PM

o-rings cost less than a dollar.

Oh wait I forgot. Do BBBs have the weird toilet plunger type o-rings?

Edited by bobafan, 10 March 2008 - 08:40 PM.

---

<death09>my girlfriend broke up with me and sent me pix of her and her new boyfriend in bed

<ktp753>ouch.

<death09>yeah.i sent them to her dad

#3

Posted 10 March 2008 - 08:58 PM

#4

Posted 10 March 2008 - 09:44 PM

Edited by Blasphemy, 10 March 2008 - 09:45 PM.

#5

Posted 10 March 2008 - 10:02 PM

#6

Posted 10 March 2008 - 10:34 PM

---

<death09>my girlfriend broke up with me and sent me pix of her and her new boyfriend in bed

<ktp753>ouch.

<death09>yeah.i sent them to her dad

#7

Posted 10 March 2008 - 11:15 PM

But I suppose if you really want a better seal than the stock plunger head replace it with a three nylon washers and an o-ring. Two of the washers should the same size as the steel washers in bobafan's diagram and one should be slightly smaller. The small washer should be sandwiched in between the larger washers to create groove for the o-ring to sit. In theory this should work better because nylon is much lighter than steel and o-rings produce less friction than gaskets and respond to lubricants better.

#8

Posted 11 March 2008 - 03:19 PM

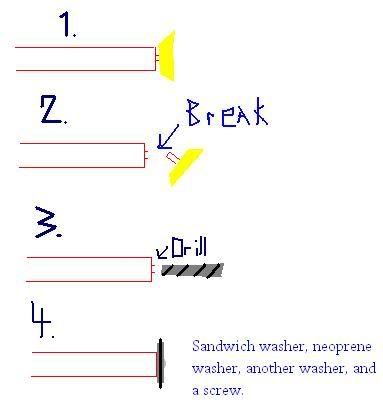

EDIT: Special Thanks to bobafan for making a nice drawing of what I was trying to describe.

Edited by Blasphemy, 11 March 2008 - 03:21 PM.

#9

Posted 11 March 2008 - 07:18 PM

Trust me, this type of seal works more effectively than O-rings on the Longshot, and should work better than any O-ring setup you come up with on the BBB. And the neoprene responds quite well to lubricant.

EDIT: Special Thanks to bobafan for making a nice drawing of what I was trying to describe.

This is Carbon's Idea with his Snap 1 Mk2 isn't it? Maybe CS proposed it before then, but I don't know.

Edited by xNFx 37, 11 March 2008 - 07:18 PM.

-Chief

#10

Posted 11 March 2008 - 07:24 PM

Anyway, I'm also planning on doing this. Look for a write up in the near future.

#11

Posted 11 March 2008 - 08:33 PM

Wow, this is perfect timing. I was going to address the poor seal issue in my up and coming BBB mod. I'll give you a little spoiler and tell you how I have done this. Full credit goes to CaptainSlug though, I took this idea out of his playbook, he used the same idea, but with the Longshot. Snap off the neck that hold the plunger seal and the piece of plastic that compresses the spring. make sure it is flush with the rest of the plunger rod. Get a #6 sheet metal screw that has a length anywhere from 1" to 2", two 1' OD fender washers, and a 1 1/4" neoprene washer. Drill a 7/64" (Or 1/8") hole in the middle of the plunger rod about the length of your screw. Sandwich the neoprene washer between the two fender washers, place the screw through the center and screw it onto the plunger rod. Run it through the plunger several times to see how it seals, it should work well, it could need some lubrication to work at its best though. I'd also recommend reinforcing the area around the plunger rod where you drilled, it should be fine, but I'm worried because the center is rather thin. You should get an excellent seal.

Yo Blasphemy, could you do this on the Xbow too? I recently got one, and, as you might know, they have a similar plunger head to what doubleshot described is on the BBB.

Edited by Salmon, 11 March 2008 - 08:33 PM.

We're located in I-Don't-Give-a-Damn County, in scenic Shut-the-Hell-Up-achussets.

Maybe you're familiar with our annual charity drive where we ask for shit, and no one gives any.

#12

Posted 11 March 2008 - 09:29 PM

But anyway I don't think it is possible with an x-bow since it has a skinny plunger rod.

#13

Posted 11 March 2008 - 10:19 PM

Yea, the BBB plunger rod is pretty beefy.God no. I don't know how you got an X-Bow, but don't fuck it up. If hear any stories about noobs fucking up x-bows I might cry.

But anyway I don't think it is possible with an x-bow since it has a skinny plunger rod.

#14

Posted 11 March 2008 - 10:35 PM

And while I can't speak for Carbon or CS themselves, I can recall what I think they said. I believe that Carbon uses gaskets because they're easier to make and when developing the original SNAP, he couldn't find a big enough o-ring. I think that Captain Slug modified his LS's plunger as such to compensate for the spring replacement.

So personally, I'll continue to prefer o-rings because I believe that they provide adequete seals and don't generate as much friction. I'll also use them because I don't want to have to lubricate it every week.

#15

Posted 13 March 2008 - 11:28 AM

#16

Posted 13 March 2008 - 12:40 PM

True. A neoprene washer has a rougher surface than an o-ring, so it requires different lubricant. I was constantly using silicone spray until I started using something with a little bit more body (in my case, Xerox fuser oil). I rarely need to relube anymore.Maybe we're using gaskets made of different materials, but I know for a fact that my SNAP's plunger dries out much more quickly than any of my modified guns with o-rings.

That's not the best guideline, mostly because a plunger operates under pressure, while the water test is not pressurized. The seal needs to be good enough to avoid blowby, which requires more friction than just watertight. Frictionless is ideal, but it's a requirement in order to create a pressurized seal.And I apologize if I said that an o-ring based plunger sealed better than a gasket based plunger. I meant to say that a o-ring plungers generally work better because they don't generate as much friction as gaskets. Spring guns shouldn't have a plunger that has a seal so tight that it impedes on it's movement. A good way to test if an existing plunger has a decent seal is to simply fill the top with water. If it doesn't leak, then the seal works. Try to get it so you get the least friction while still being able to hold water.

This also varies depending on how tight your foam fit is. My foam is a lot tighter than most people's foam, so I need greater pressure to fire a dart than someone else might. In order to achieve greater pressure, I need a plunger seal capable of holding greater pressure without leaking. The opposite is also true.

More accurately, it was because the tolerances of the parts I was using; I just couldn't fit an o-ring in there. When I first started using the rubber washers, I was under the impression that the seal was created by the washer cupping forwards. As I look at wear patterns on seals I’ve been using for a while, I’m not convinced that this is the case. I think the seal is bending backwards, and wedging itself in between the endcap, acting like an o-ring. Since the endcap has slight angle to its side, it makes for a good variable seal.And while I can't speak for Carbon or CS themselves, I can recall what I think they said. I believe that Carbon uses gaskets because they're easier to make and when developing the original SNAP, he couldn't find a big enough o-ring.

Edited by Carbon, 13 March 2008 - 12:41 PM.

#17

Posted 13 March 2008 - 02:01 PM

A few thoughts:

True. A neoprene washer has a rougher surface than an o-ring, so it requires different lubricant. I was constantly using silicone spray until I started using something with a little bit more body (in my case, Xerox fuser oil). I rarely need to relube anymore.Maybe we're using gaskets made of different materials, but I know for a fact that my SNAP's plunger dries out much more quickly than any of my modified guns with o-rings.

Yeah, it all depends on the lubricant you use. I use high-quality silicone grease. It can be found in the plumbing section at most hardware stores, it is the same stuff Forsaken_angel24 uses. Although the stuff is more expensive than spray lubricant it lasts a lot longer, I haven't ever needed to re-lube any of the blasters I lubricate with it, I imagine I wouldn't need to re-lube any of my gasket setups either, including this one.

EDIT: Carbon, since it was originally your idea I'll put you in the credits too.

Edited by Blasphemy, 13 March 2008 - 02:02 PM.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users