Here's a torn apart pic of the gun.

Here's a constructed pic of the gun with the normal dart barrel.

http://i258.photobuc...er/IMG_8529.jpg

Here's my lovely wiring. It's just a simple series circuit.

Here's a side by side barrel comparison pic that shows the ball attachment and the dart attachment.

http://i258.photobuc...er/IMG_8547.jpg

Hooked to an air compressor.

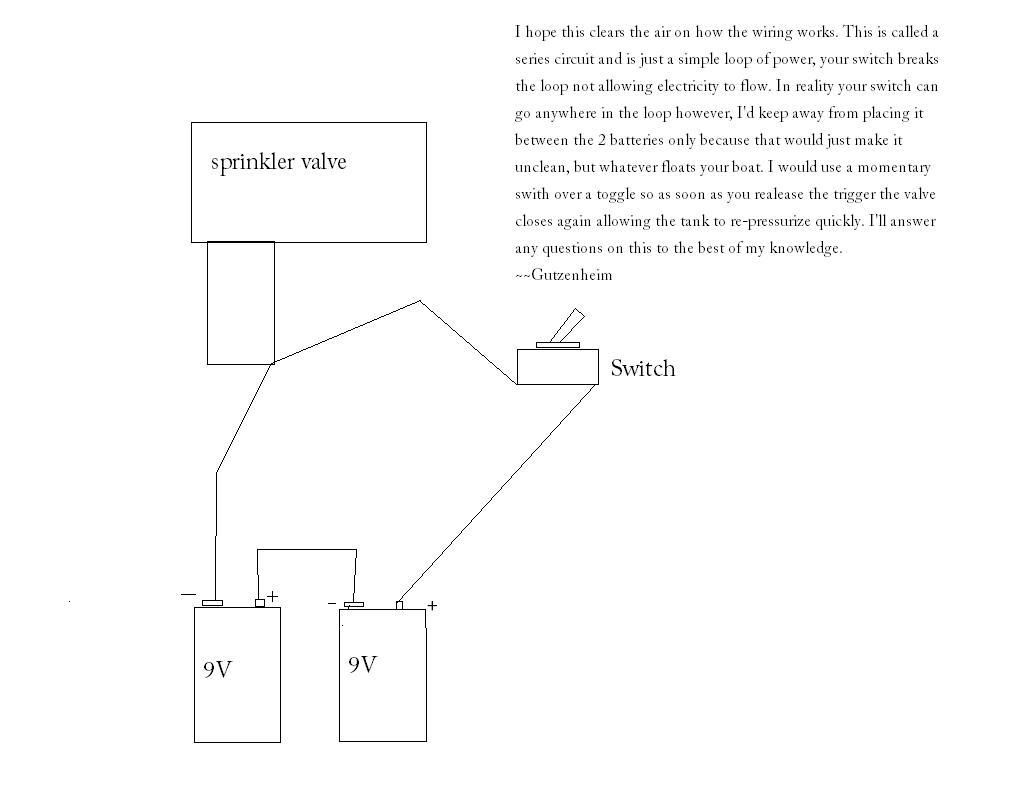

I've had some questions on wiring so here's an explanation of how it's done.

I'm sorry, but I can't give you stats as far as distance and those things go at this point in time because I don't have a long enough range to fire it yet and it's very cold outside here now. I will, though when given the chance do all my official testing. I will however say that it does indeed rock a nerf dart at only 50psi and splits them at 100psi. I hope you like my first gun and view my 2nd gun which should be on here either today or tomorrow.

~~Gutzenheim

Edited by Gutzenheim, 08 March 2008 - 08:49 AM.