#1

Posted 02 February 2008 - 12:41 AM

First, I don't think all this primer stuff and proper use of all it is completely necessary. When I made my first homemade gun, my dad did pretty much all the solvent welding part. From what I've heard on the internet, his way of doing it is really really bad. He didn't use any primer, and then he used all purpose cement. It's pretty old too, it's kinda really gooey... unless that's what it's supposed to be like (The can says don't use if its jelly like). But! It gets a 100% air seal and hasn't failed at around 90 PSI. So whatever.

Well I'm making a gun that uses 2 inch PVC so I need to make sure its better this time. I've heard lots of different techniques all over from searching... but I'm pretty sure theres different primers and cements.

Priming. The can I have says "For PVC, CPVC, Purple Primer". This might be really old since it's my dad's and he doesn't think it's necessary. It still has the consistency of water though. First of all, are you supposed to put like a huge amount on? Or just a really light coat. Then, are you supposed to wait for it to completely dry before adding cement, or right after you add primer do you put cement on?

Cementing. This can says "Regular, Clear, PVC Cement". Well first of all, I can't even get this open! I don't want to risk damaging it by using pliers, since it might be cemented shut and I'll have to return it. Once I do get this open though, how much do I put on? Do I put it on only one end, or both.

Another thing, not really related to solvent welding. I need to convert 2 inch PVC to 1 inch PVC, and I can't really find the right connectors. I found 2" to 1-1/2", but it says NSF-DWV which I'm pretty sure means not pressure rated. It also doesn't look like a lot of the pipe would fit into it, maybe 3/4".

MAIN POINTS:

-Is primer supposed to be wet or dry before adding cement?

-Does PVC Cement come really hard to open when you buy it?

-Can NSF-DWV pipe be used for pressure?

#2

Posted 02 February 2008 - 12:53 AM

1. I don't think all this primer stuff and proper use of all it is completely necessary.

2. Is primer supposed to be wet or dry before adding cement?

3. Do I need to apply primer and solvent to both parts?

4. Does PVC Cement come really hard to open when you buy it?

5. Can NSF-DWV pipe be used for pressure?

6. I need to convert 2 inch PVC to 1 inch PVC, and I can't really find the right connectors.

1. It is. The surface of the PVC is very glossy and resists chemical penetration since it has a relatively low surface area that makes adhesion kind of difficult (comparatively). The primer roughens the surface allowing the adhesive to make a good mechanical bond between the two piece that's much stronger than if you didn't prime.

2. The primer dries so fast and is so easy to apply I don't see the reasoning behind NOT using it. You don't have to apply very much, just one brushing over the whole area you're trying to cement, then wait for it to dry a bit.

3. Yes. Light coat of solvent on both parts then hammer them together using a wood plank and a sledgehammer or rubber mallet.

4. Sometimes. Use a wrench to open it.

5. No, only use pipe that's marked SCH40 or SCH80. Gravity feed fittings should not be used with pressure either.

6. You will need a bushing adapter (2" to 1" SCH40 adapter) and a coupler (2").

Edited by CaptainSlug, 02 February 2008 - 12:56 AM.

#3

Posted 02 February 2008 - 12:58 AM

So those bushing adapters can be used for pressure? Does anything that says NSF-pw mean it can be used for pressure?

#4

Posted 02 February 2008 - 01:15 AM

Here are the abbreviations: http://nsf.org/busin...tion_page4.html

Edited by CaptainSlug, 02 February 2008 - 01:16 AM.

#5

Posted 02 February 2008 - 03:16 PM

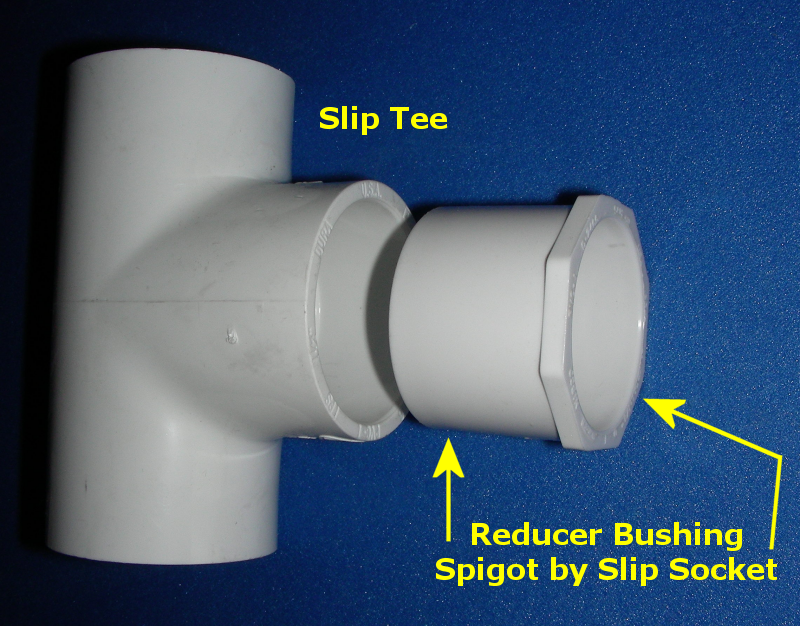

-2" x 1" Sch 40 PVC Spigot x Slip Bushing

-2" Sch 40 PVC Slip Coupler

The coupler slides into the spigot? And then the slip slides into the pipe?

#6

Posted 02 February 2008 - 04:27 PM

The bushing adapter gets solvent-welded into the coupler because its OD is the same as the 2" pipe.

Edited by CaptainSlug, 02 February 2008 - 04:32 PM.

#7

Posted 06 February 2008 - 05:12 PM

"5. No, only use pipe that's marked SCH40 or SCH80. Gravity feed fittings should not be used with pressure either." -CaptainSlug

You should be careful here making a distinction. Schedule-40 and Schedule-80 are actually only designations of dimension, they actually don't say anything specific about working-pressure of a pipe. In order to verify a pipe is rated for pressure applications look for "NSF-pw". Pressure rated fitings and pipe will always have this designation. HOWEVER, they also typically come with other designations as well. Virtually all pressure rated pipe and fittings will have a NSF-dwv rating as well (you could if you wanted use NSF-pw PVC for drainage, waste etc, but it's overkill). So just because the pipe is marked with dwv doesn't mean it isn't also pressure rated, just be sure to check first.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users