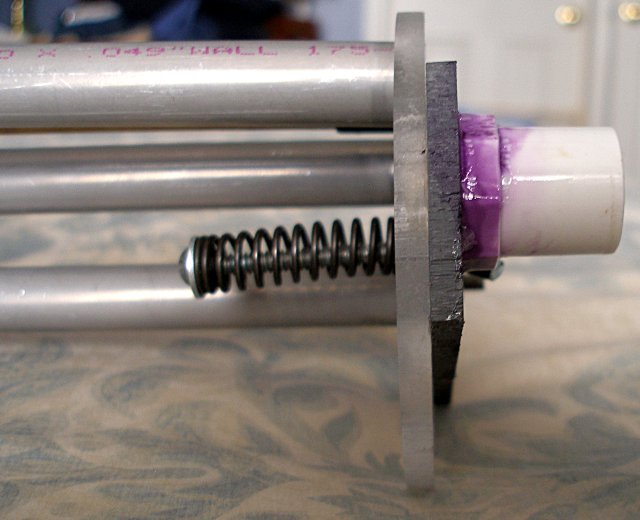

This design features easy rotating barrels, indexing, and a good seal without lubrication or any sort of sealing material. I've found that the plastic on plastic seal is pretty good as is in this design. I can't say there is any loss in range because I did not test range. Blowing into the coupler seams to seal very well after I upgraded the spring to a fairly strong one. And as I said, that's without sealing material or lubrication.

There are only four barrels attached to this because I did not have enough material for more. The turret itself can have 8 barrels. Aluminum is good for this because it has an OD of 5/8 inches, is light, and has low friction. The holes I drilled in the acrylic sheet were 5/8 inch holes. The brass tube I stuck in with electrical tape, but it wouldn't be held in as solidly without the aluminum. Note that I didn't use any glue at all to keep the aluminum in. Glues simply were not necessary.

The acrylic that I used to make the parts that attach to the barrels is not the best material for that job. PVC would be best in my opinion because you can attach PVC fittings to it very easily and it is much easier to machine. The dark gray plastic used is PVC sheet. I only had about as much as I used, so the acrylic was used for the remainder. If you want to use PVC barrels, I would suggest PVC because it would be very easy to attach a coupler or half a coupler to a PVC sheet.

You don't get a very good view of the indexing mechanism with the barrels in the way, so below is a picture of it.

I used a circular screw head to index the turret. This works great. The head is smaller than 1/2 inches in diameter so I didn't have to be too precise in my measurements. The barrels can be moved a bit when locked in place, but not enough to affect flow.

I'd write more, but my brain's fried right now. Wednesday is my busy day at college. I attend University of Maryland and I made this because I wanted to attend a Nerf war or two in the spring by the Nerf club, but since my Max Shot doesn't seem reliable enough, I'll probably build a quick spring gun and attach this to it. Once I buy some more aluminum, this plus a good spring gun should be a dangerous combination.

Feel free to ask any questions you have about this or its construction. I might edit in some more later too.

Edited by Doom, 30 January 2008 - 09:39 PM.