#1

Posted 12 January 2008 - 11:14 PM

I will be using a pretty big pvc tank for the reason I am using the ball valve as a trigger. Now i need to know the best way of connecting the pump to the gun? I don't really want anything to complicated and i really want it to be quite small and portable.

im using

15mm ball valve

15mm cpcv ( barrel)

Cpcv tank (undecided on cpcv size )

by the way I know ball valve releases the air slow but i am really going for the mass of air and not really release speed.

Any advice please? Id be happy to be corrected if I say anything wrong since this is the first homemade i am making from scratch and my second homemade built (my first was the SNAP)

=[

#3

Posted 12 January 2008 - 11:57 PM

[===}>&>-------------

Tank, reducer, ball valve, reducer then barrel.

The "mass of air" will act the same if the barrel isn't generously long, unless it fires bigger foam (not megas, mongos or rockets).

#4

Posted 13 January 2008 - 12:03 AM

-DTR

That's it. I'm done. I'm sorry there are breasts on the Internet.

#5

Posted 13 January 2008 - 04:07 AM

and what tank should i use then

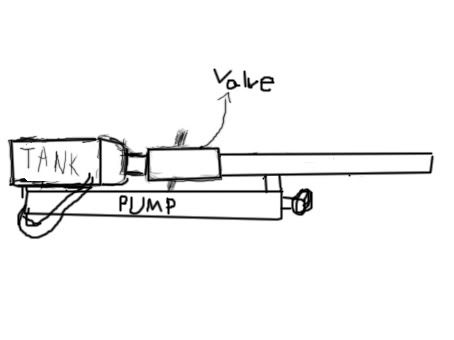

here is my plan

or something similar and don't worry I am putting a pressure gauge on the tank.

I think a small pump would be to slow to fill the tank so a standing bike pump would be best?wouldn't it? .

Again any comments or help would be very good.

Edited by ltvills, 13 January 2008 - 04:28 AM.

=[

#6

Posted 13 January 2008 - 07:51 AM

http://nerfhaven.com...zero_ballvalve/

Edited by P.C. III, 13 January 2008 - 07:51 AM.

Don't want to shove balls in tight spaces. Trust me, bad idea.

For sale: Vintage WWII French rifles. Dropped once, never fired.

#7

Posted 13 January 2008 - 08:33 AM

If you use a standing pump, they have the gauge, but it wouldn't be worth the time to pump it like a titan when you could use a dual action bike pump. Target has some nice ones for 10-18 bucks.

#8

Posted 13 January 2008 - 04:54 PM

50psi on cpcv tanks is the limit right ?

what if i reinforce it would i get better pressure?

=[

#9

Posted 13 January 2008 - 06:05 PM

For a single shot high tank volume blaster like this you really don't need to fill beyond 35psi anyways.

Edited by CaptainSlug, 13 January 2008 - 06:07 PM.

#10

Posted 13 January 2008 - 07:39 PM

#11

Posted 13 January 2008 - 08:23 PM

I think you want to build something like:

http://www.nt3.idv.t...pb_arsenal.html

Right?

#12

Posted 13 January 2008 - 08:28 PM

It doesn't matter what kind of PVC is used. CPVC comes in more sizes than just 1/2" CH80.Why a CPVC tank?

Unless it's a really crappy pump, they usually have them built in. Otherwise they wouldn't be capable of inflating tires.Use a check valve to interface with the bike pump.

You will only NEED a check valve with a normal bike pump if you are planning to remover the pump from the gun after filling it.

Edited by CaptainSlug, 13 January 2008 - 08:30 PM.

#13

Posted 13 January 2008 - 09:36 PM

any yes RAMBO something similar to that namely the boost but only 1 ball valve will be used

=[

#14

Posted 13 January 2008 - 09:45 PM

Your most accessible option will be screw-in valve stems, which you can buy from any auto parts store.what if i want the pump to stay on the gun what is my best choice of connecting the pump on

Edited by CaptainSlug, 13 January 2008 - 09:45 PM.

#15

Posted 14 January 2008 - 12:37 AM

check valve or tire stem valve

what sizes do these valve come ?

and the price ranges please.?

=[

#16

Posted 14 January 2008 - 01:38 AM

You will only NEED a check valve with a normal bike pump if you are planning to remover the pump from the gun after filling it.

For once I am going to be able to prove you wrong (not that it matters, and not to rub it in, just pointing it out).

I've had pump handles get bent in process of pumping. This, in a war scenario, is a bitch if the pump is sealed into any form of PVC on the gun. It provides much more flexibility and versatility to have the pump be removable and transferrable between guns - in my opinion.

Stem valves will probably be cheaper - you'll want want to size it based on you bike pump - my gut says get a 1" stem or check valve, since that's most likely what your pump will be, but check your pump first.

I would like to point something out for you, though - when working with two ball valves, this allows you to have multiple shots without repriming your gun. The PVC behind the first valve acts as a tank. The PVC between the two valves acts as a charge for the dart in the chamber. Keep the second valve closed when firing your shot, or leave it open for an exceptionally powerful shot. Just a thought - might be better to experiment without this part first.

#17

Posted 14 January 2008 - 01:25 PM

The need for a check valve specifically is only there if you want to fill the tank with a pump then disconnect the pump and not loose any air. There are other ways of linking pumps to the tanks of homemades that still allow the pump to be removed, without having to buy a check valve.I've had pump handles get bent in process of pumping. This, in a war scenario, is a bitch if the pump is sealed into any form of PVC on the gun. It provides much more flexibility and versatility to have the pump be removable and transferrable between guns - in my opinion.

If you have a stem adapter, tubing, and a fitting on your tank you can use the pump to fill the tank. Removing the pump is possible, but doing so empties the tank.

Stem adapters are kind of hard to find in 5/32" OD, but you will really only need one if you don't need to have a pump permanently mounted on each homemade.

The dollar store ball pumps that 3DBBQ uses are nothing more than a tube and a plunger, hence why all of his designs include a check valve. To use any other decent bike/tire pump you won't need to have the check valve.

The valve stem is the best thing to use because they're cheap, very easy to find, and you won't need any other parts.just a question what is easier to find and where could i find them

check valve or tire stem valve

what sizes do these valve come ?

and the price ranges please.?

A valve stem has a check valve built into it. Standalone check valves can be kind of expensive to buy locally anyways and you would need a fitting, fitting, and stem adapter in order to use it with a bike pump.

Valve stems only come in one OD (5/32) and there usually aren't very many length options. Just get the longest one the store has.

Price range is anywhere from $3 to $8

Edited by CaptainSlug, 14 January 2008 - 01:35 PM.

#18

Posted 14 January 2008 - 09:06 PM

#19

Posted 15 January 2008 - 05:34 PM

do you mean the inside lining of bike wheels?

=[

#20

Posted 16 January 2008 - 04:47 PM

what do you mean blown tubes?

do you mean the inside lining of bike wheels?

Exactly.

#21

Posted 16 January 2008 - 05:56 PM

=[

#22

Posted 16 January 2008 - 10:35 PM

Your all set then, just make sure you get a good seal, sometimes its kinda tricky. Make sure to pile on the plumbers goop or whatever you use, just don't cover the hole in the bottom accidentally, and double check the seal before you solvent weld the gun together.sweet i have a blown wheel from neighbors bike.

#23

Posted 16 January 2008 - 10:57 PM

I would honestly not suggest this I tried it once bad mistake thing leaked like no other and was just a pain in the ass its easier just to shell out like 3-4 dollars and get a set of two pop in stem valves from like walmart. No gluing no muss no fuss over it just drill and pull it through the hole its that easy. Honestly you can do whatever you want but I speak from experiance and its just easier.Your all set then, just make sure you get a good seal, sometimes its kinda tricky. Make sure to pile on the plumbers goop or whatever you use, just don't cover the hole in the bottom accidentally, and double check the seal before you solvent weld the gun together.sweet i have a blown wheel from neighbors bike.

-DTR

That's it. I'm done. I'm sorry there are breasts on the Internet.

#24

Posted 17 January 2008 - 02:02 AM

=[

#25

Posted 17 January 2008 - 05:59 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users