So I fixed the valve again, and it seems to be permanent.

This is better than my previous method.

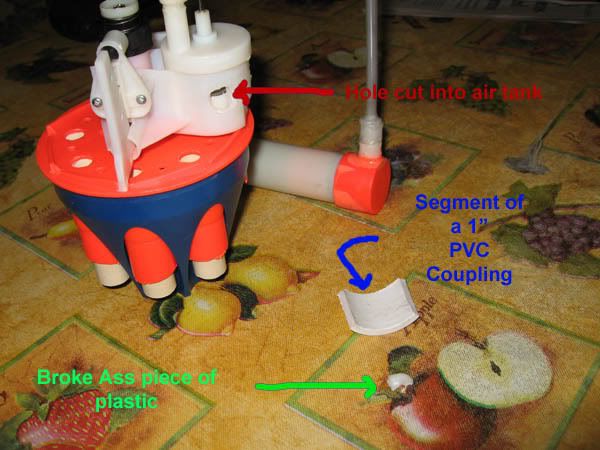

First, you need to cut the airtank in half horizontally. I suggest that you use a dremel and draw lines using a sharpie so you can line up how the tank was originally oriented when you glue the thing back together. Be careful not to cut the turret's vital moving pieces! As far as I could tell, the turret couldn't be removed from the tank.

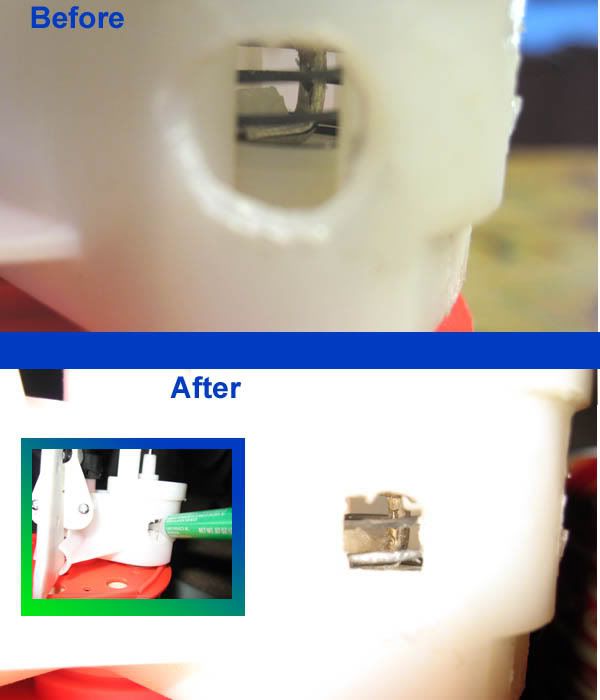

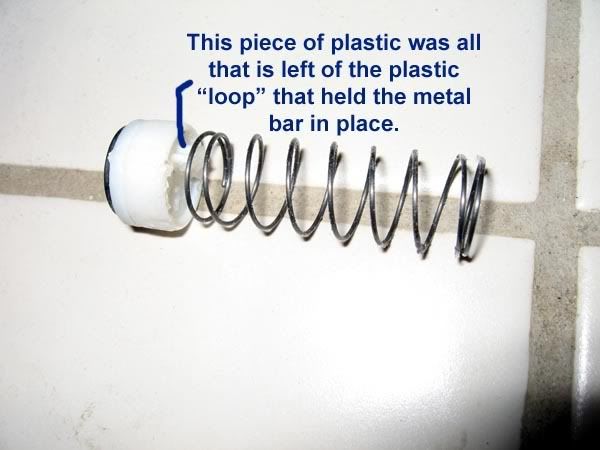

Here is where the terminal breakage occured on my SM3000

That little plastic nub used to have a plastic loop attached. The metal bar that actuated the valve pulled this front valve piece (the part that seals the front of the tank) by pulling on the loop. When pulled, the front valve piece would move backwards into the tank and release the air. The loop broke after some use, so the gun would not release air when firing.

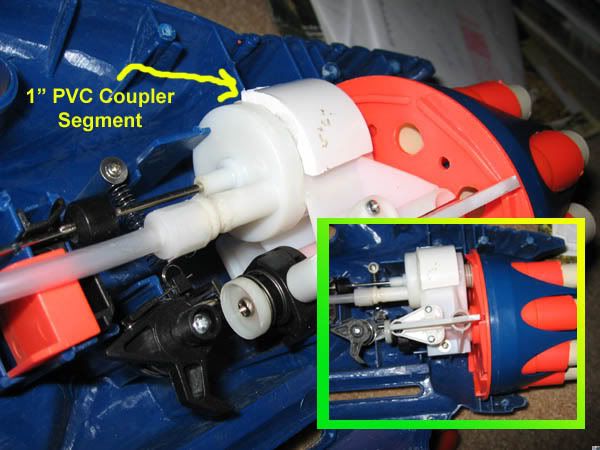

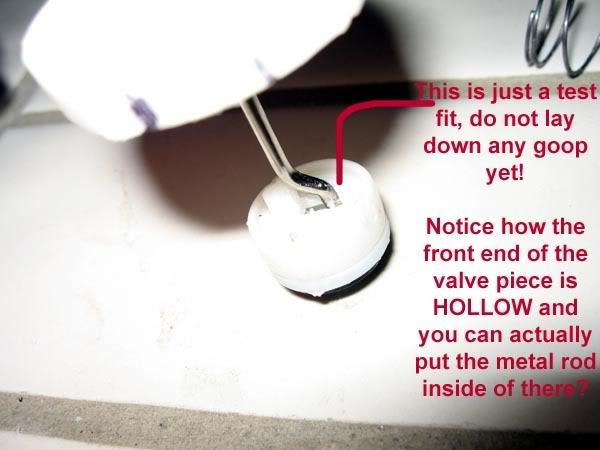

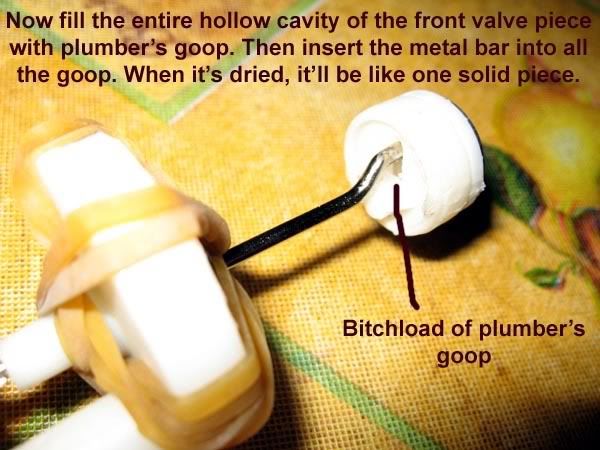

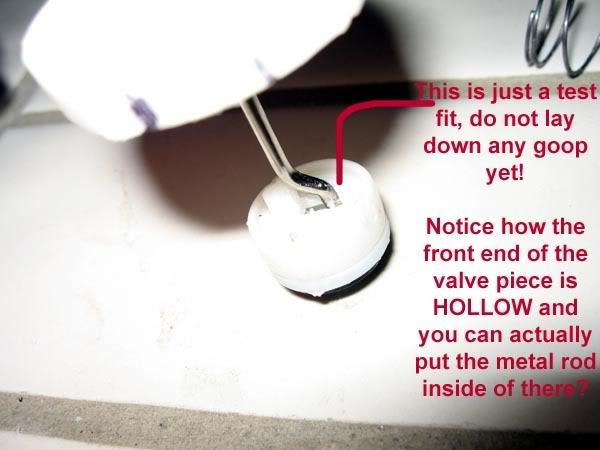

Secondly, you want to goop the metal bar directly to the front valve piece. How should we approach this? Well, I found something interesting about the front valve piece--it is actually hollow! So I tested a theory and here's what I got:

The metal bar can actually fit inside of the piece (it has 90 degree bend at the end of the bar, which is the part that goes into the front piece). Anyways, don't goop anything into place just yet because you still need the spring inbetween there (otherwise the tank won't seal when you pump it up. It will be stuck "open").

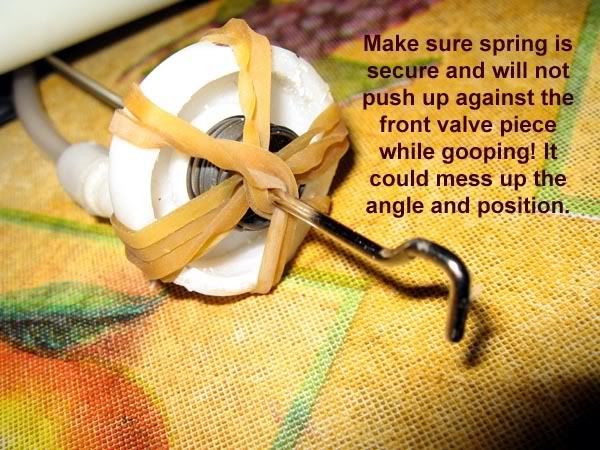

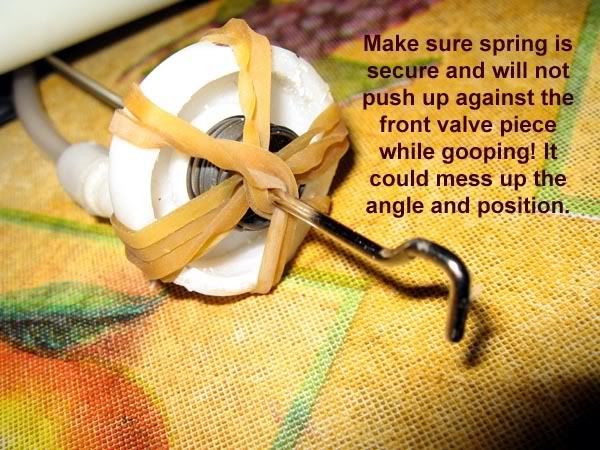

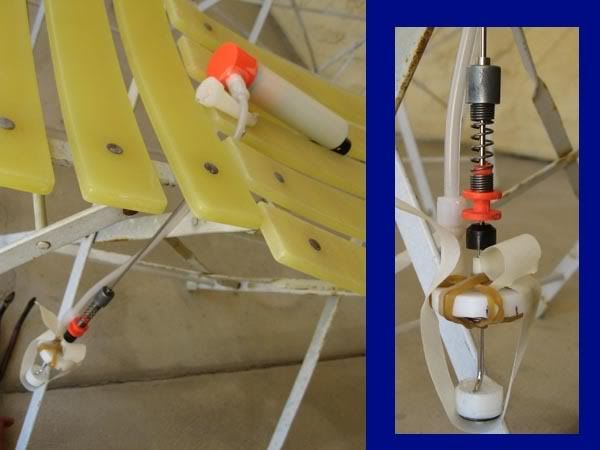

Here is what my set-up looks like:

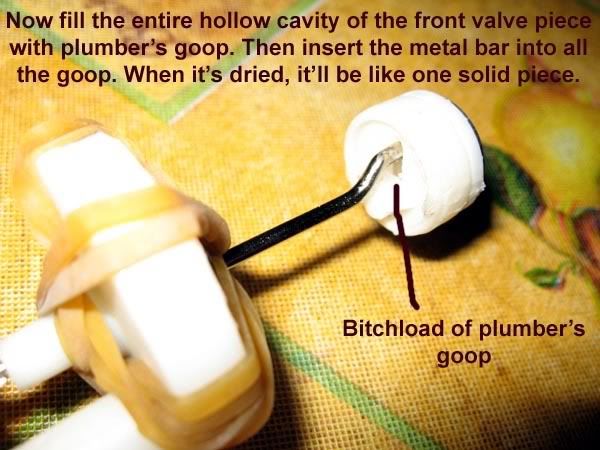

The rubber bands are there to keep the spring from touching the gooped connection while it dries. This would ensure that they don't dry at some funny angle or something. Additionally:

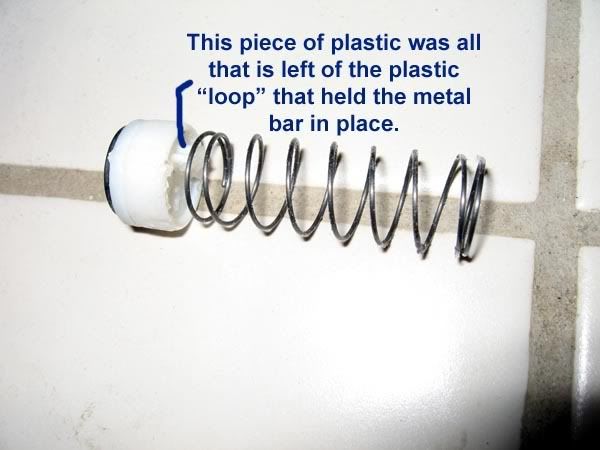

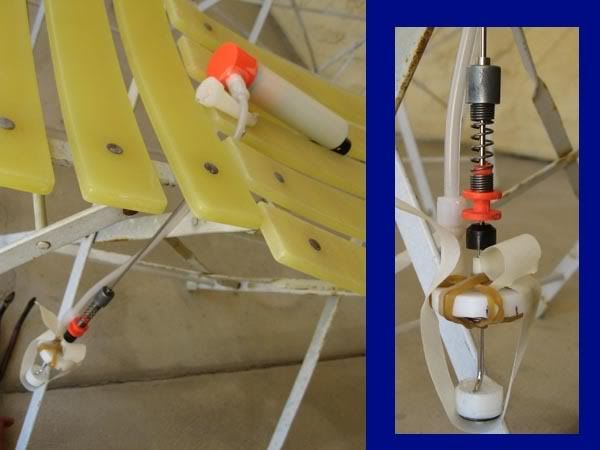

This is how I let it dry. I wanted it hanging down vertically so the front valve piece will be perpendicular to the front of the tank once I re-gooped the halves together. If your front valve piece is not oriented correctly when you goop the tank back together, the gun will not seal! Take care in making sure it is centered and at the right angle. I let it dry for 3 days before cutting the rubber bands and letting the spring rest up against it.

That is the end of the difficult part! There are some additional steps that you need to do before the gun will be working again:

1) Spray silicone lube on black rubber portion of the front valve piece (for good seals).

2) Goop the tank back together again (you may need clamps/rubber bands again since the spring will want to keep the tank from closing together). Be sure to use plenty of goop, line up the sharpie marks you made earlier, and not to accidentally goop the turret together! I also recommend cleaning out as much dust and plastic bits inside the tank as possible.

3) Reassemble the gun.

I find that this method works because the metal rod pulls directly on the front valve piece now. It does not pull on a weak plastic loop, nor does it pull on a chemical bond made by adhesives (previous method). The only way this will break now is if the entire front valve piece falls apart, and even that is more unlikely now that it's practically a solid mound of plumber's goop!

Hope this was of some help to somebody out there!

Edited by frost vectron, 01 December 2007 - 07:23 PM.