I browse the forums fairly regularly and sometimes I see something that really impresses me. In this case, it was actually a Longstrike! It's not often you get all hot and bothered by a blaster that absolutely blows stock. However, nowadays I see blasters in a different light than I used to. Now that I have the means to create any of my own components, there's no point in reusing Hasbro's internals at all. A blaster's worth to me is now measured in how good it looks and how easy it is to incorporate internals and other goodies. The Longstrike satisfies all my requirements, and just happens to have enough room for a 1.5'' PVC plunger tube! This mod is literally a wolf in sheep's clothing--the shell is the only thing left that's actually stock.

Here's the Longstrike I got for free:

The bolt was stuck, so the owner probably tried to open it up, realized it was solvent welded, and gave up. Sweet!

Required Materials:

- 1.5'' clear PVC pipe

- 6-32 threaded rod

- 1 1/4'' to 1/2'' PVC bushing

- 6-32 Keps nut x4

- 3/8'' length 6-32 set screw x4

- 1/2'' length 6-32 set screw x2

- 1/4'' polycarbonate sheet

- 1/8'' polycarbonate sheet

- 6-32 nylon spacer x2

- 3/4'' length 6-32 screw x4

- 6-32 shoulder screw

- Small, strong spring for catch

- [k26] mainspring

- 1/2'' round Delrin rod

- Spud gasket (for toilets)

- 1'' length 6-32 screw

- 3/8'' length 6-32 screw

- #6 washer

- U-cup or piston cup ()

Required Tools:

- Scroll saw

- Screwdriver

- Drill press

- Hand drill

- Dremel

Write-up:

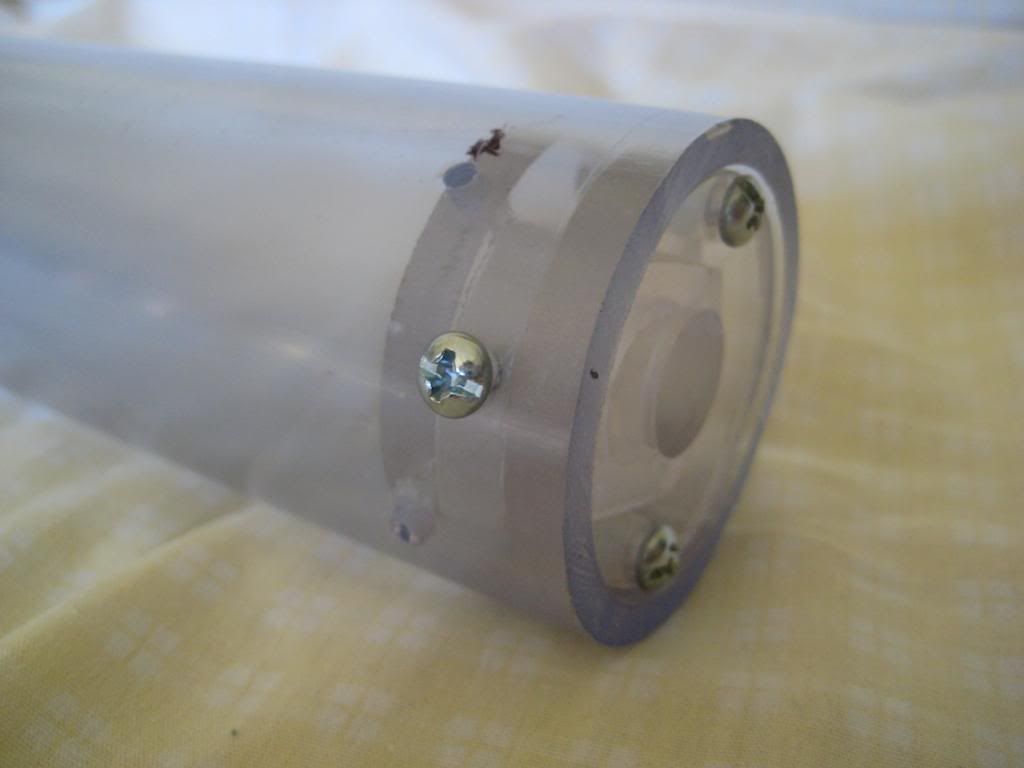

Let me start out by saying that taking apart this blaster can be a huge bitch. There were orange pieces randomly solvent welded into place that actually kept the two halves of the shell from separating. Suffice it to say, I ended up using the Dremel as a samurai sword and severing anything in my path. I think it's a conspiracy by Hasbro to prevent people from modding blasters with too much real estate inside them. Anyways, eventually I cracked the egg. Start by cutting the plunger tube. It should be a whopping 14'' in length:

Now to prepare the front bushing. I secured the bushing in between two fender washers, tightened nuts on both ends, and put it in the drill press.

I used my "ghetto lathing" method to shave down the bushing with a Dremel until it fit nicely into the plunger tube. Use some PVC solvent to permanently attach the bushing with an airtight seal:

Now for the worst part of the mod--Dremeling the shell to fit the plunger tube. You can make things a little easier by cutting out the gloryholes that I did:

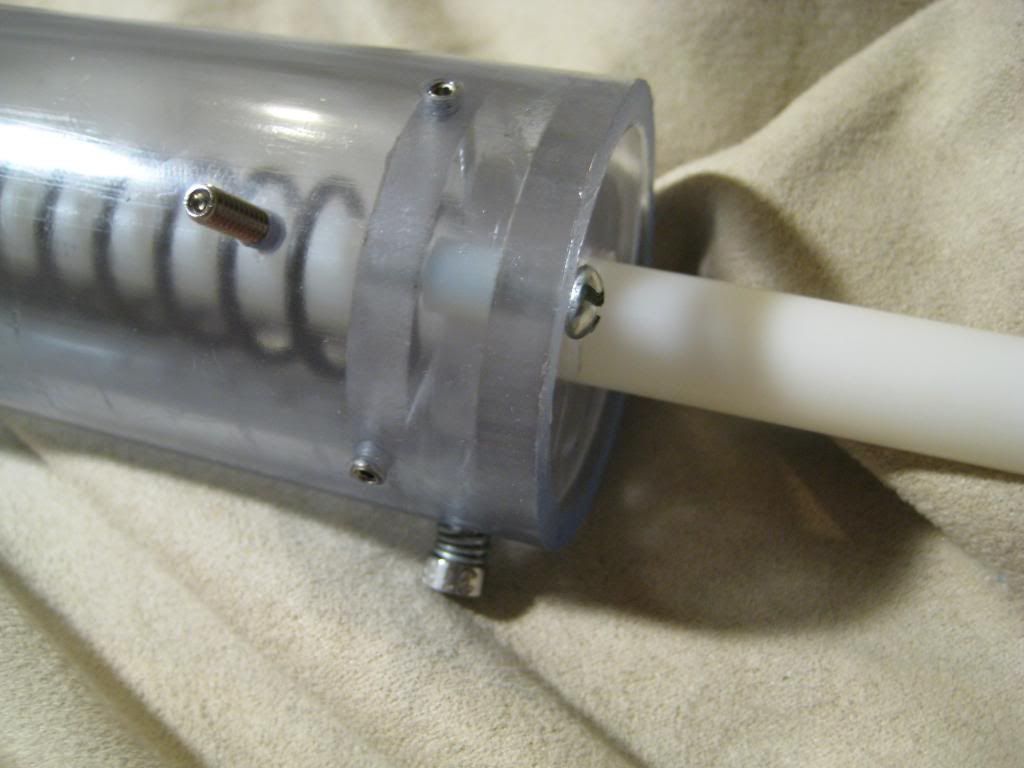

Dremeling the shell proved so frustrating that I even forgot to take a picture of it. Just keep checking the fit with the plunger tube until it fits. The front of the plunger tube should be flush with the front of the shell as well. Anyways, let's finish up the plunger tube. This requires the construction of a Rainbow Catch. I did a write-up on how to make a 1.5'' Rainbow Catch with no templates here.

Stick it in the back of the plunger tube and mark where the shoulder screw will pass through. Drill the hole with the 5/32'' drill bit, then use a small screw to hold the catch in place for more drilling.

Drill four holes with the 7/64'' drill bit through the plunger tube and into the inner ring of the catch. Tap them all.

Now that the rear end is prepared for duty, it's time to put the threaded rod through the front bushing. Drill through with the 7/64'' bit, tap, and insert the threaded rod. Drill 9/64'' holes in the shell at the front for the threaded rod. Add glue around the threads to prevent air leakage. Fail to do this and you won't get the perfect seal!

Put the plunger tube in place and enclose it in the shell. Then drill a 7/64'' hole through the shell and plunger tube on either side towards the rear of the blaster. Expand the holes in the shell with the 9/64'' bit. This step is just to insure that the plunger tube has adequate support.

Last order of business is plunger padding. I used a healthy amount of toilet gasket to kill some dead space and insure that the blaster doesn't destroy itself:

Now on to the plunger rod. Cut a 14'' length of Delrin rod and drill (and tap) one end of it with the usual 7/64'' drill bit.

Here is my plunger head. From left to right: 1'' screw, #6 washer, 1/4'' polycarbonate disc, <1/4'' polycarbonate disc, U-cup, 1/4'' polycarbonate disc.

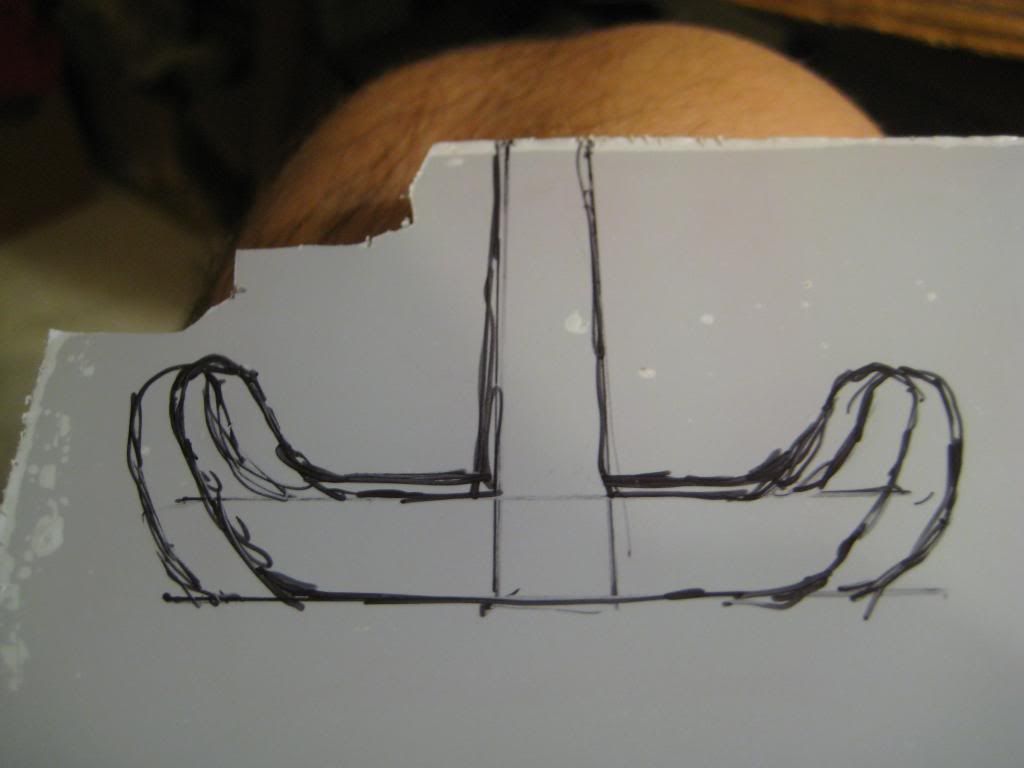

In order to prime the blaster you need to fabricate something here is what I made:

I attached it to the end of the plunger rod with a couple of 3/4'' screws. Later I ended up trimming down the sides, since I was getting some facerape holding my head against the stock while firing.

Here is the plunger rod assembled. As you can see, my U-cup was a bit large. Regardless, the seal is perfect. I have discovered recently that 1.5'' OD piston cups plunger heads are the ideal choice for 1.5'' PVC.

Don't forget to Dremel the back of the shell for the new priming rod:

Put the assembly in the blaster and get a friend. Prime the blaster all the way back and get a friend to make a mark right where the rod leaves the shell. The front of the catch notch will be cut 3'' in front of the mark:

Reassemble everything again, and we're almost through! Here are some shots of the completed plunger tube:

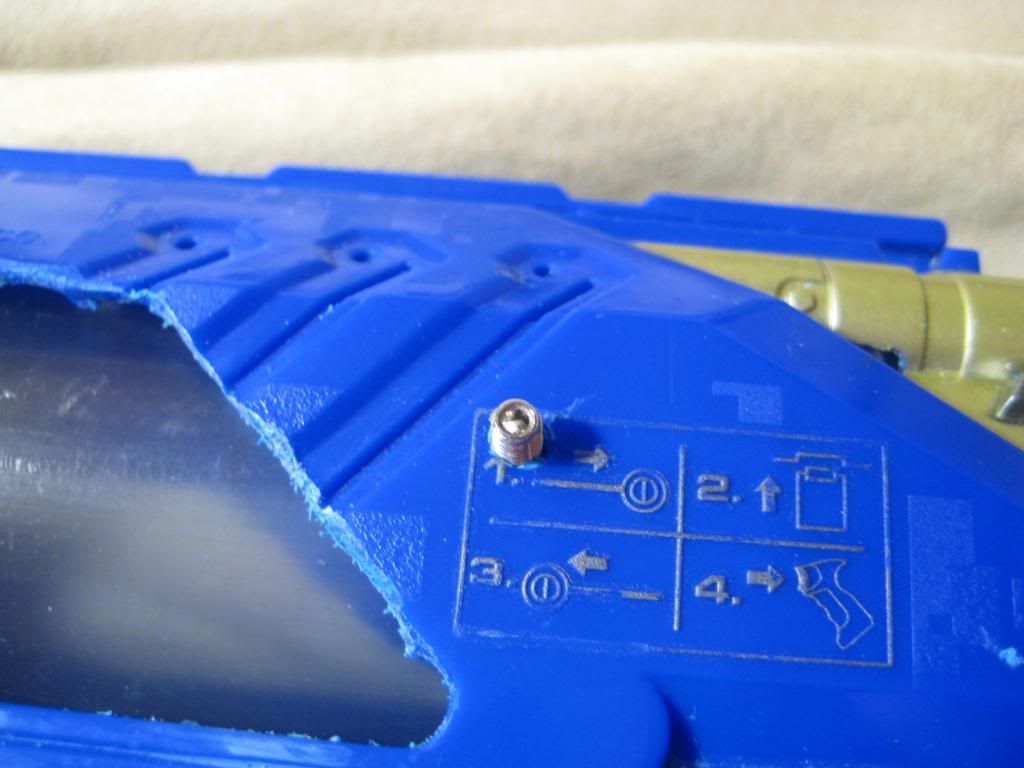

Now for the final challenge--making the trigger! Obi, the original creator of this mod cautioned that this would be the hard part, but I thought about it for a while and arrived at a simple and elegant solution. First, a piece of the shell must be trimmed in order to accommodate the trigger:

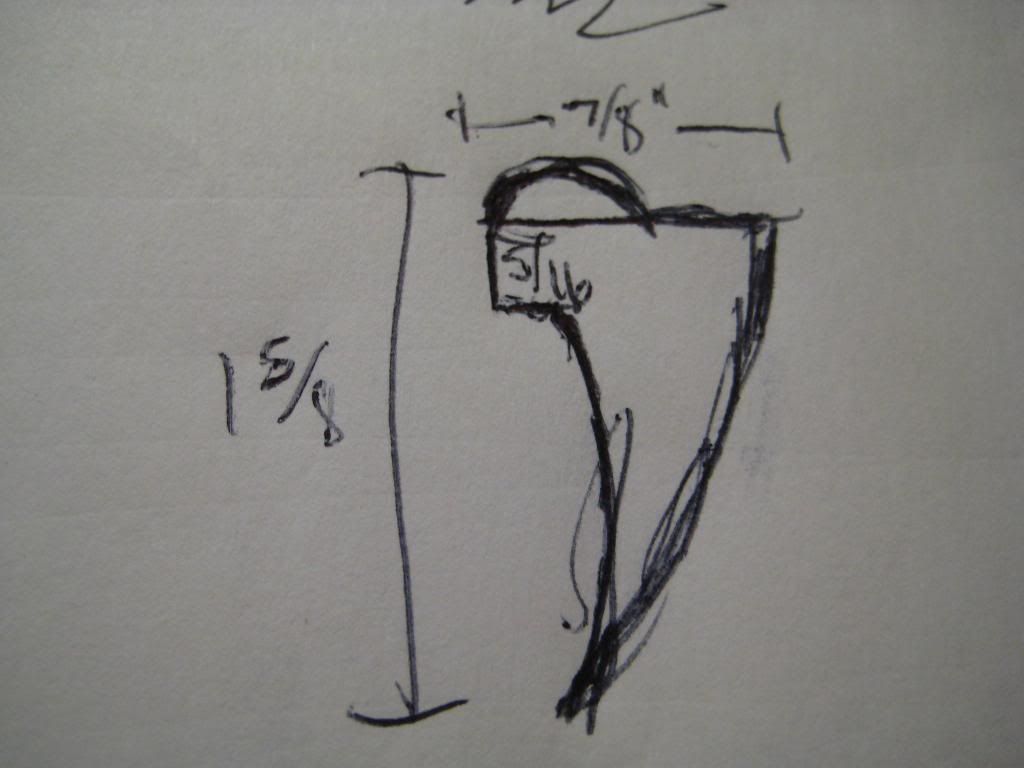

Here are some tentative schematics I used for the trigger. The final product was a bit taller and wider:

Here is everything needed for the trigger setup. The trigger is 1/8'' polycarbonate, the mount is 1/4'' PC, and the screw is a 3/8'' screw.

The piece of polycarbonate is 3/8'' wide and 7/8'' tall. It has been drilled and tapped with the 7/64'' drill bit and goes here:

The rest is simple:

And the rest is history! Put it all back together (without forgetting the rail mount pieces) and marvel at what the Longstrike wished it could always be:

Cutaways are nice, so you can see full compression in action!

Conclusion:

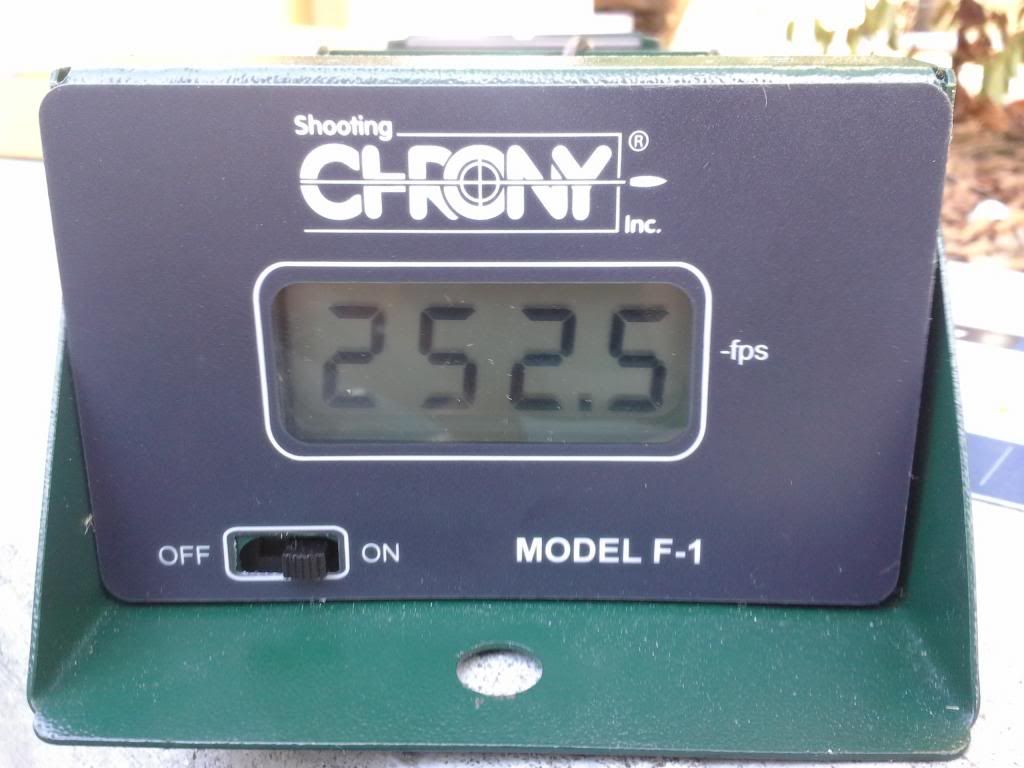

Damn, what a blaster. It seems like even a 16'' barrel is no problem for this bad boy. With over 7'' of draw, this thing could actually put an eye out. Many thanks to Obi, the modder I followed--you are a gentleman, scholar, and general baller. Hopefully this writeup brings hope to those who have lost faith in the Longstrike. One thing I could have done better was move the priming handle closer to the plunger tube to avoid face-diddle, but it may be unavoidable with over 7'' of draw. Here is the average velocity:

Not bad, considering the plunger head is too fat. Perhaps my 16'' barrel was too short as well--I'll have to make a 2-footer for blasters like this! In any case, I'll be revisiting this blaster farther down the road for one final mod--a shotgun grip

Cheers,

~T