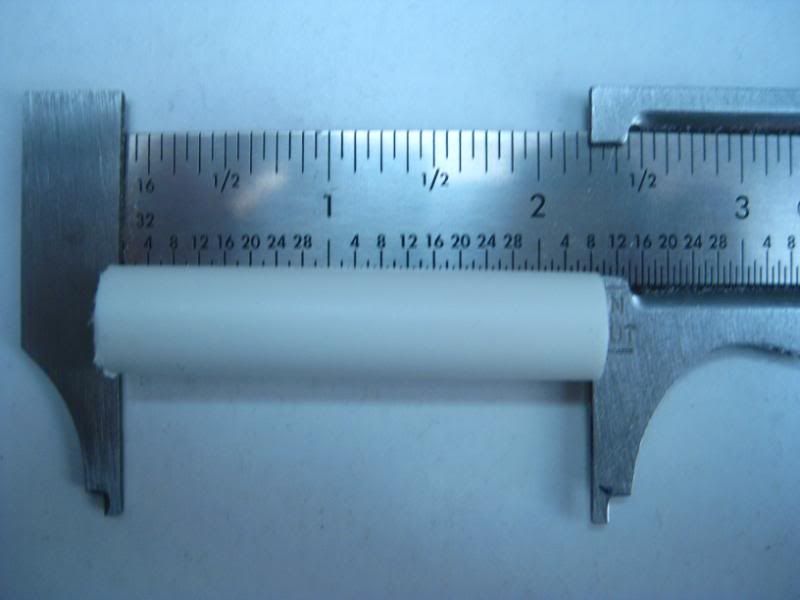

I cut a 2 1/4" Long piece of 1/2" OD 3/8" ID PEX Tubing.

I drilled a small hole in the middle of the PEX

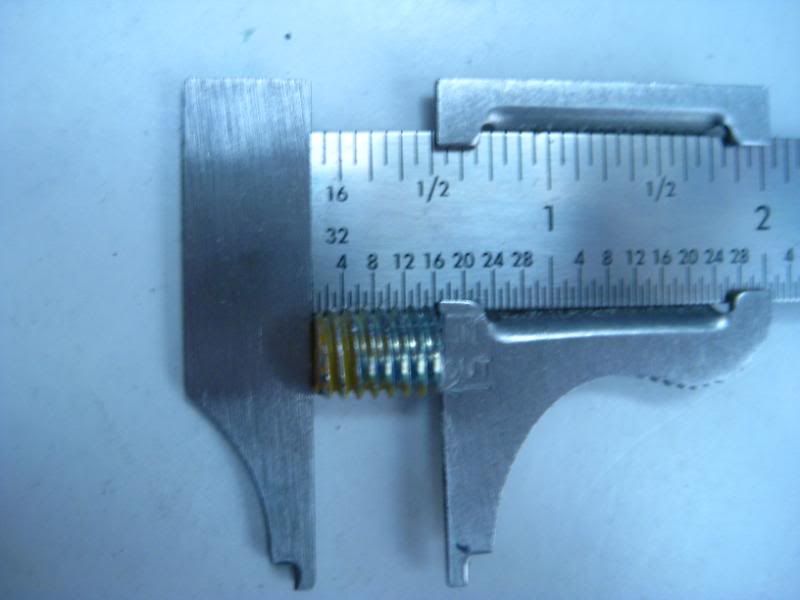

I cut a 1/2" Long Piece of 3/8-16 Threaded Rod.

I smoothed out the ends of the threaded rod with a file and bench grinder. I then dremeled a notch into it to make a set screw.

I tapped one end of the PEX with a 3/8-16 Tapping Bit.

I drilled into the PEX about 1.5" with a 3/8" Flat Wood Boring Bit on the opposite end.

I tapped the drilled end with a 1/8-27 NPT Tapping Bit.

I cut two pieces of vinyl tubing. One piece of 1/4" ID 3/8" OD and one of 1/8" ID 1/4"O OD tubing. Both should be around 5/8" in length.

I sanded the outside of each of the pieces of vinyl tubing a bit. I made sure that one of the ends of the 3/8" OD tubing is very flat and even. I then carefully applied Plumbers Goop using toothpicks all around the 1/4" OD tubing and inserted it into a 1/8" NPT Brass Fitting that has a barb for 1/4" OD tubing. I pushed it in as far as it could go. I than pushed the 3/8" OD tubing over the 1/4" OD tubing. I applied goop all over the 3/8" OD tubing and the Brass Fitting then pushed/threaded it into the end of the PEX that was tapped with the 1/8-27 NPT bit.

I cleaned off the excess Goop with a rag. I let that dry for 24 Hours. Once the Goop cured I inserted a 5/16" Ball Bearing, a small but strong spring, and the set screw.

The end product:

I set the pressure by adjusting the screw. I use my portable compressor set-up for this as well.

DEMONSTRATION VIDEO

Edited by venom213, 20 February 2011 - 02:43 PM.