Foreward:

Start by unscrewing the blaster. One thing I did notice is that the Sharp Shooter is what I call a "pistol' version of the crossbow. I mean the internals are the exact same, just different demensions and shell! (Plunger head, plunger tube, etc.)

Immidiatly grab the plunger rod and mark out a new catch almost directly after the original one. Make sure you use some perminant marker that way it will stick and wont rub off.

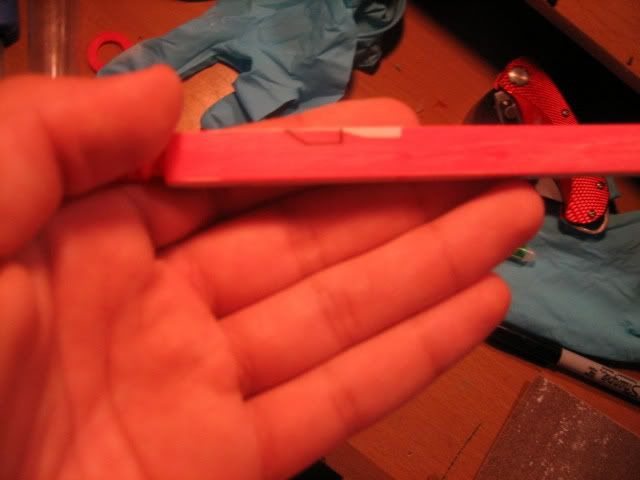

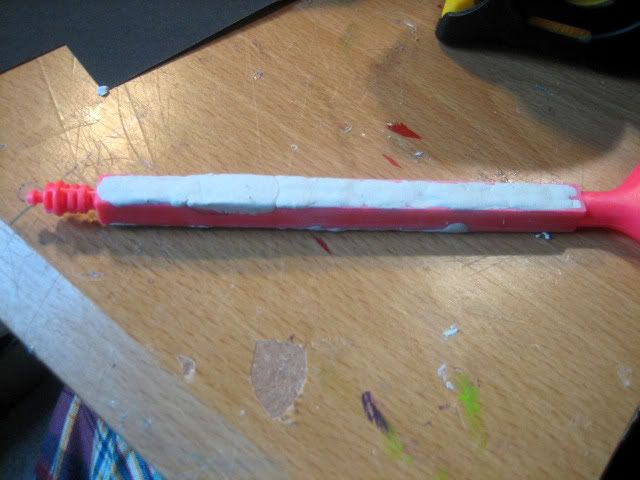

Take some sandpaper and sand down the plunger rod. Every inch! Now grab a tube of Mighty Puddy(in honor of Billy Mays) and go to town on the plunger rod, fill in every inch of space including the origianl catch. If theres alot over flowing remove it while its still soft. If you do it now it will mean less sanding later...Make sure you get both sides too. If you are really parinoid about your SSI breaking you can do the end where pull on. I decided against it because I felt it was not needed.

Now set aside your plunger rod while it dries and lets start the work on the plunger shall we? Chop the barrel off as close to the plunger tube as possible.

Go grab your file and/or dremel and slowly widen the hole until you can fit 15/32nds brass into the hole you create. I used a conical dremel bit to widen the hole at first then widened it with the file. Once that is done wash out the plunger tube to rid it of any stray plastic shavings.

Let's start on the barrel assembly.

First lets start by cutting our brass.

1 1/2 inch of 15/32nds brass

3/8ths of an inch of 1/2 inch brass

3/8ths of an inch of 17/32nds brass

4-5 inches of 9/16ths brass to be your barrel.

Take your 15/32nds brass and flare out one of the ends to recieve better air flow.

With your needle nose pliers in hand thread the piece of 15/32nds brass through the gaping hole in the plunger head. The next part is challenging, make sure that the 15/32nds brass is in the correct place. I did this simply by using an extremely bright light and the plunger rod asembly (plunger head pushes the brass until it's in the right spot.) Once it's in the correct spot super glue it in place.

Look closely you will see it get larger ass you put each size up of brass on it:

Get your 9/16ths brass barrel and be sure to add some tightening rings 1/2 inch from the base to keep the diameter the same when you add the barrel over the 17/32nds brass. Wrap it in etape, lether on some plumbers goob the add some PVC to cover the brass.

Go out to your workshop and flip on your dremel and make room in the shell to compensate for the extra thickness provided by the PVC. Basicly make it about the same with the ridge before it. Do this on both sides

Edited by CoasterDynamix757, 24 July 2009 - 09:57 PM.