This modification will make your ERTL Rapid Fire Shotgun (often referred to as the Doomsayer) shoot harder and further than before.

Materials needed:

-LS plunger tube

-Stock RFDG plunger tube

-Hacksaw/Dremel

-Sandpaper

-Measuring tape

-BBB arrow

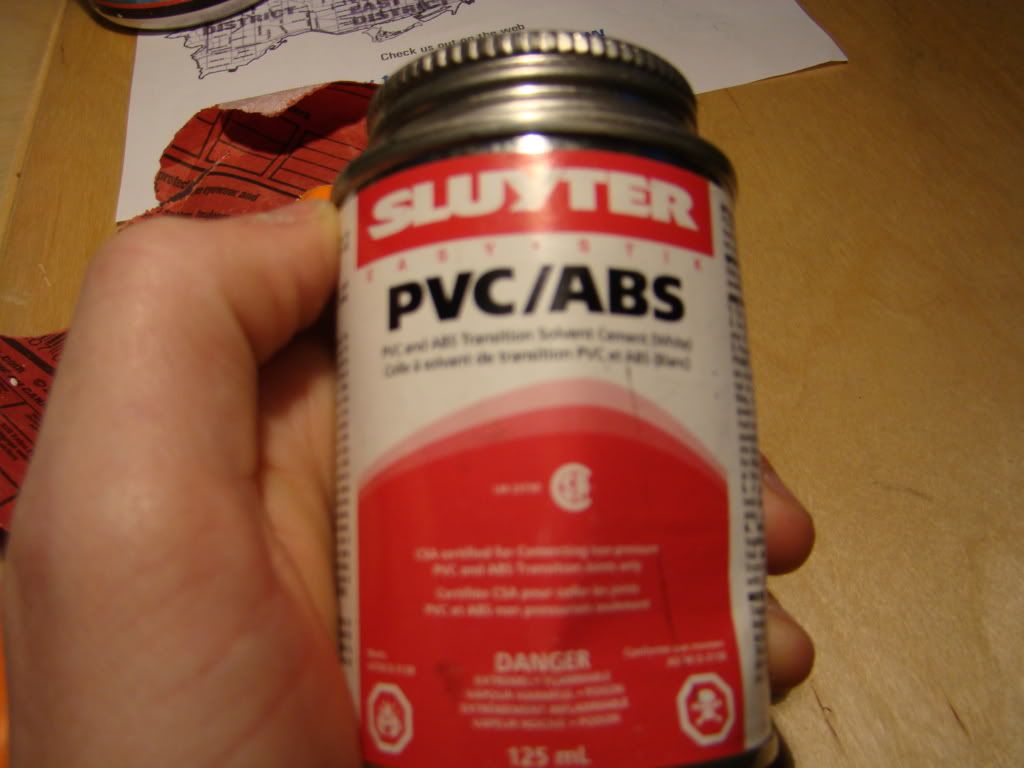

-PVC/ABS transition cement

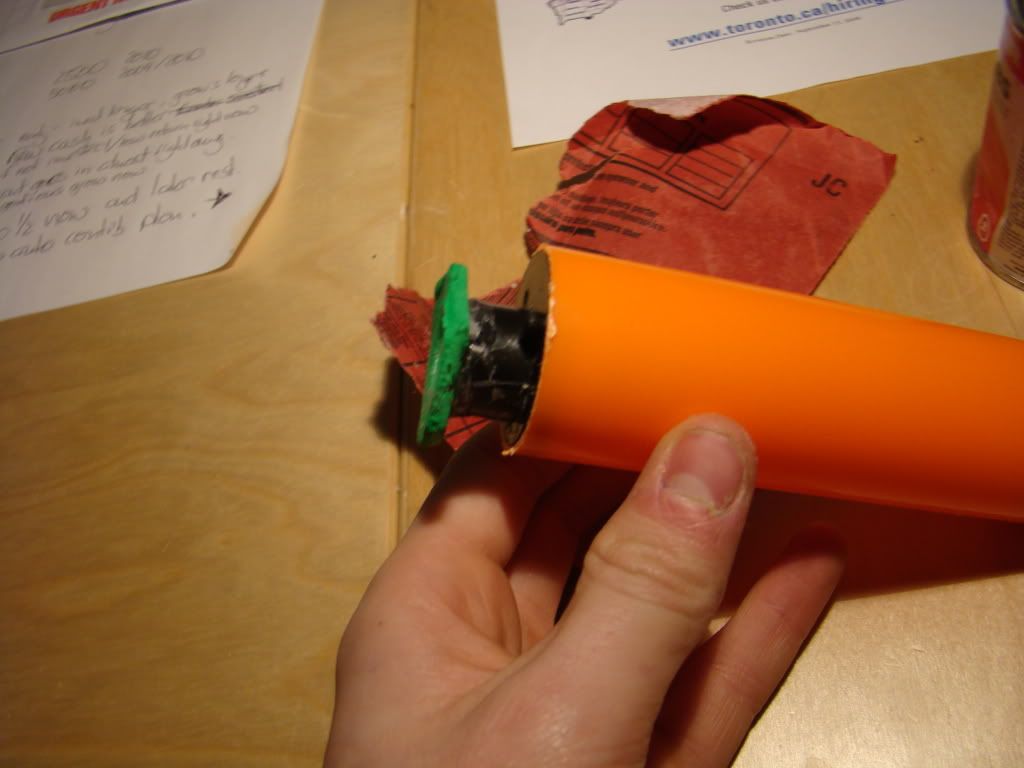

Take the plunger tube out of your RFDG and cut it down like so. Ignore the green thing at the end, that is my plunger tube/turret sealer.

Now, take your stock LS plunger tube and sand off those ridges and that nub that keep it in the LS. Cut it down to 4 7/8 inches.

Now, take your sandpaper and sand out your desired front end of the LS plunger tube. The bit you cut off your RFDG plunger tube needs to fit in there. It won't without a bit of sanding.

PIC

The parts should fit nicely together like this:

Next, take your piece of BBB arrow (thin piece) and glue it into the front of your RFDG plunger tube bit like so. Make a hole for the air to get through. That serves as plunger padding, and it's much easier to add it now.

Next, cement the two together using this stuff:

Your RFDG should fit together with minimal sanding of the ridges keeping the PT in place. I wrapped a shitton of electrical tape around my RFDG plunger head to get it to fit, but if you have tapping bits, I would tap a hole in the end of the RFDG plunger rod and use a LS plunger head replacement. Your RFDG should be shooting considerably farther now. Mine with a stock/BBB spring gets similar ranges to FA_24's that had the stock PT and an extra spring in there. This is easier to prime, and gets similar ranges.

Find content

Find content