So, I recently got a RF20 from goodwill, and found that the pump was broken. I took it back to my workshop and fixed the pump. Unfortunately, I found that when I pumped it up and pulled the trigger, the gun just hissed and did not fire.

I've also had this same problem happen to a magstrike I found, and then sold for parts. Has anyone else had this problem?

Is the valve just fucked or what?

Thanks for Looking

- NerfHaven

- → Viewing Profile: Topics: Renegademilitia15

Renegademilitia15

Member Since 15 Jan 2008Offline Last Active May 05 2012 02:09 PM

Community Stats

- Group Members

- Active Posts 516

- Profile Views 8,296

- Member Title Member

- Age 31 years old

- Birthday December 7, 1992

User Tools

Latest Visitors

Topics I've Started

Magstrike/rf20 Question

25 February 2010 - 07:11 PM

Lbb Coupler Extension With Nf Integration

28 August 2009 - 01:34 PM

If you may recall a while ago, I posted a mod for the LSB that was a FAILBOAT. I ended up destroying the integrity of the blaster, and it now hangs on my lonely wall of shame.

However, I recently acquired an Lbb with no monetary loss of my own ( Thanks BlackFox ), and finally decided what to do with said blaster. So, with out further ado:

Pinky and the Brain

Supplies Needed:

HOTGLUE

Amazing Plumbers Goop

E tape

1/2 in. SCH 40 PVC

9/16ths brass

19/32nds Brass

3 1/2 in. Sch40 Pvc Couplings

Ace#49 spring

Tools Needed:

DREMEL

Hotglue Gun

Band saw

Screw drivers

This writeup will come in two parts. First, the NF mods, then the LBB Mods.

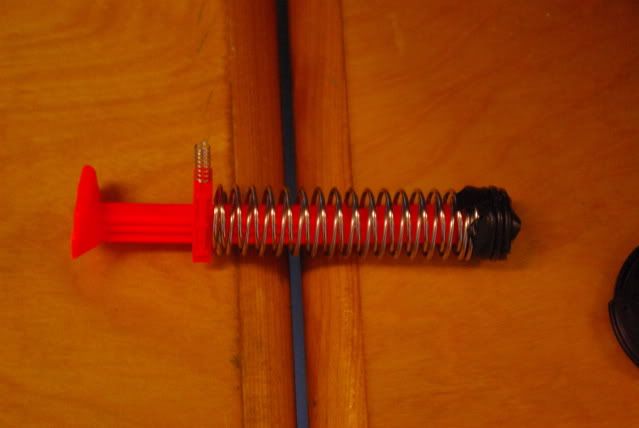

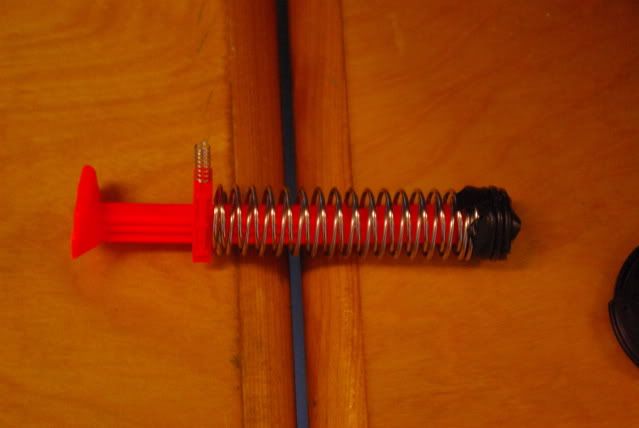

Act 1: Pinky

First take your NF, open it up and remove all the useless AR drivel. Then take the plunger rod out, etape and lube the plunger head, and then swap out the wimpy stock spring for the Ace #49 one. I had some spring shenanigans after this picture, so these aren't the actual springs I used. But, you get the picture.

Like so:

Then take your band saw ( or dremel, if you prefer to be messy ), and cut off the handle, ammo holders and cocking handle of the NF, then with your dremel, widen the barrel hole on the front enough to accommodate a coupler.

For some reason, I must have huge couplers where I live, because I couldn't get it to fit in the plunger tube at all. So I had to grind out the outer edge of the coupler to fit over the plunger tube. Once it fits properly, Goop away!

Finished NF:

Act 2: The Brain

Take your Lbb, open it up and cut off the orange stock barrel.

Then take 2 couplers, a length of 1/2 in. pvc, and a length of 19/32nds Brass. You have to make the the couplers and PVC long enough to be just beneath the barrel hole of the Lbb. If you've got it figured out, make sure to hotglue the couplers and the PVC together. If it leaves you a little confused, just wait. There's a picture of this assembly in a bit.

There!

Then take your band saw, and cut off the entire trigger gaurd.

Finished Lbb:

Act 3: The joining

If you cut off the trigger guard of the Lbb, there should be a rectangle shaped box on the underside of the Lbb near the front just begging for something to be put there. And if you put it there, and cut off the cocking handle, the plunger rod should just fit right before your hand.

After its been secured there, Hotglue the crap out of it.

Finished sexiness:

With an 8in. brass barrel for the lbb, and a 3in. brass barrel for the NF, this is what turned up:

Nf: 58ft, 61ft

Lbb: 91ft, 96ft

I didn't actually do the 19/32nds nesting part, because my crappy adhesive skills, but I'm pretty sure that would put the Lbb ranges into the 100s region. I also found that you can fire the NF in two ways. 1) Angle it up a tidge ala M203 style. 2) flip the entire blaster upside down, and viola! you have a NF-like rifle.

Questions, Comments, and Flames are welcome here in mai threadz.

However, I recently acquired an Lbb with no monetary loss of my own ( Thanks BlackFox ), and finally decided what to do with said blaster. So, with out further ado:

Pinky and the Brain

Supplies Needed:

HOTGLUE

Amazing Plumbers Goop

E tape

1/2 in. SCH 40 PVC

9/16ths brass

19/32nds Brass

3 1/2 in. Sch40 Pvc Couplings

Ace#49 spring

Tools Needed:

DREMEL

Hotglue Gun

Band saw

Screw drivers

This writeup will come in two parts. First, the NF mods, then the LBB Mods.

Act 1: Pinky

First take your NF, open it up and remove all the useless AR drivel. Then take the plunger rod out, etape and lube the plunger head, and then swap out the wimpy stock spring for the Ace #49 one. I had some spring shenanigans after this picture, so these aren't the actual springs I used. But, you get the picture.

Like so:

Then take your band saw ( or dremel, if you prefer to be messy ), and cut off the handle, ammo holders and cocking handle of the NF, then with your dremel, widen the barrel hole on the front enough to accommodate a coupler.

For some reason, I must have huge couplers where I live, because I couldn't get it to fit in the plunger tube at all. So I had to grind out the outer edge of the coupler to fit over the plunger tube. Once it fits properly, Goop away!

Finished NF:

Act 2: The Brain

Take your Lbb, open it up and cut off the orange stock barrel.

Then take 2 couplers, a length of 1/2 in. pvc, and a length of 19/32nds Brass. You have to make the the couplers and PVC long enough to be just beneath the barrel hole of the Lbb. If you've got it figured out, make sure to hotglue the couplers and the PVC together. If it leaves you a little confused, just wait. There's a picture of this assembly in a bit.

There!

Then take your band saw, and cut off the entire trigger gaurd.

Finished Lbb:

Act 3: The joining

If you cut off the trigger guard of the Lbb, there should be a rectangle shaped box on the underside of the Lbb near the front just begging for something to be put there. And if you put it there, and cut off the cocking handle, the plunger rod should just fit right before your hand.

After its been secured there, Hotglue the crap out of it.

Finished sexiness:

With an 8in. brass barrel for the lbb, and a 3in. brass barrel for the NF, this is what turned up:

Nf: 58ft, 61ft

Lbb: 91ft, 96ft

I didn't actually do the 19/32nds nesting part, because my crappy adhesive skills, but I'm pretty sure that would put the Lbb ranges into the 100s region. I also found that you can fire the NF in two ways. 1) Angle it up a tidge ala M203 style. 2) flip the entire blaster upside down, and viola! you have a NF-like rifle.

Questions, Comments, and Flames are welcome here in mai threadz.

Computer Problem

29 May 2009 - 05:55 PM

The games I run on my computer run really really fast. Like press the forward key and you run half way across the map fast.

This mostly happens to the FPS's that I run, and I have absolutely no idea how to fix this.

Please Help! If it helps, I know that I have a Radeon 9800 pro video card.

This mostly happens to the FPS's that I run, and I have absolutely no idea how to fix this.

Please Help! If it helps, I know that I have a Radeon 9800 pro video card.

At2k Stock V.2

26 February 2009 - 12:45 AM

You may recall a write-up written many moons ago by me when I first got validated here. After looking over that write-up, and seeing some of the criticism I got, I decided to make it better.

So..........

At2k Stock V2

A very small list of Supplies:

A crutch

1/2 in. CPVC

one 1/2 in. CPVC Coupler

Hotglue/plumbers goop

hacksaw/band saw/dremel

First, cut a hole in the back of your at2k. Be very careful, because there is some tubing right behind the hole were you are cutting. Like this:

(Picture from old write-up)

Then cut a small peice of CPVC, and stick in the aforementioned hole, and apply Amazing Goop profusely. Make sure the piece is long enough to fit a coupler securely on the back. Like so:

Then, take your coupler and glue it on to the front of the metal pipe protruding from the crutch. Then for aesthetics, I glued a crossbar of CPVC to make it look sweet.

When you've done all of that^^, it should look like this:

The stock should securely fit on the the back of the at2k, and It also shouldn't be that hard to get off.

Finished product:

With all the comfiness of the crutch stock, and the versatility of the PVC removable stock.

Questions? Comments?

Edit: Hotglue is shit.

So..........

At2k Stock V2

A very small list of Supplies:

A crutch

1/2 in. CPVC

one 1/2 in. CPVC Coupler

Hotglue/plumbers goop

hacksaw/band saw/dremel

First, cut a hole in the back of your at2k. Be very careful, because there is some tubing right behind the hole were you are cutting. Like this:

(Picture from old write-up)

Then cut a small peice of CPVC, and stick in the aforementioned hole, and apply Amazing Goop profusely. Make sure the piece is long enough to fit a coupler securely on the back. Like so:

Then, take your coupler and glue it on to the front of the metal pipe protruding from the crutch. Then for aesthetics, I glued a crossbar of CPVC to make it look sweet.

When you've done all of that^^, it should look like this:

The stock should securely fit on the the back of the at2k, and It also shouldn't be that hard to get off.

Finished product:

With all the comfiness of the crutch stock, and the versatility of the PVC removable stock.

Questions? Comments?

Edit: Hotglue is shit.

Mav Question

15 February 2009 - 04:36 AM

I'm having a little spot of trouble modding a mav for my friend.

I removed all of the AR parts, and I have a pretty good seal with the turret, but when I cock it and fire, the dart doesn't leave the barrel.

So when you do an AR removal to your Mav, do you remove the three pronged thingy's and the spring, but leave the pegs in with them drilled out?

Thanks.

I removed all of the AR parts, and I have a pretty good seal with the turret, but when I cock it and fire, the dart doesn't leave the barrel.

So when you do an AR removal to your Mav, do you remove the three pronged thingy's and the spring, but leave the pegs in with them drilled out?

Thanks.

- NerfHaven

- → Viewing Profile: Topics: Renegademilitia15

- Terms of Service and Privacy Policy

- Code of Conduct ·

Find content

Find content