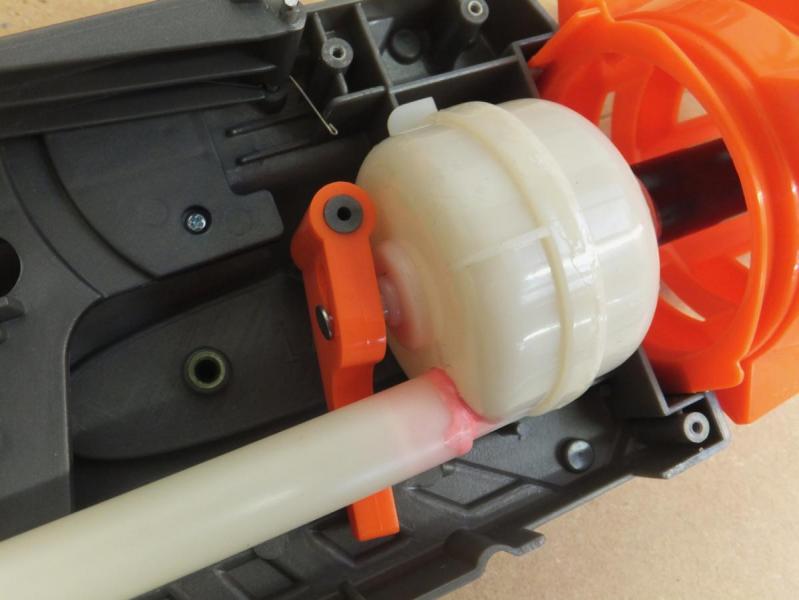

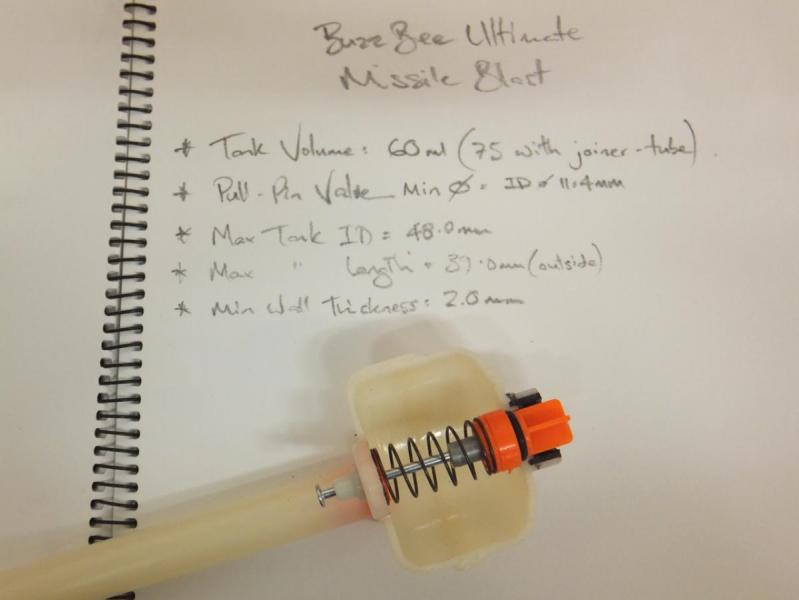

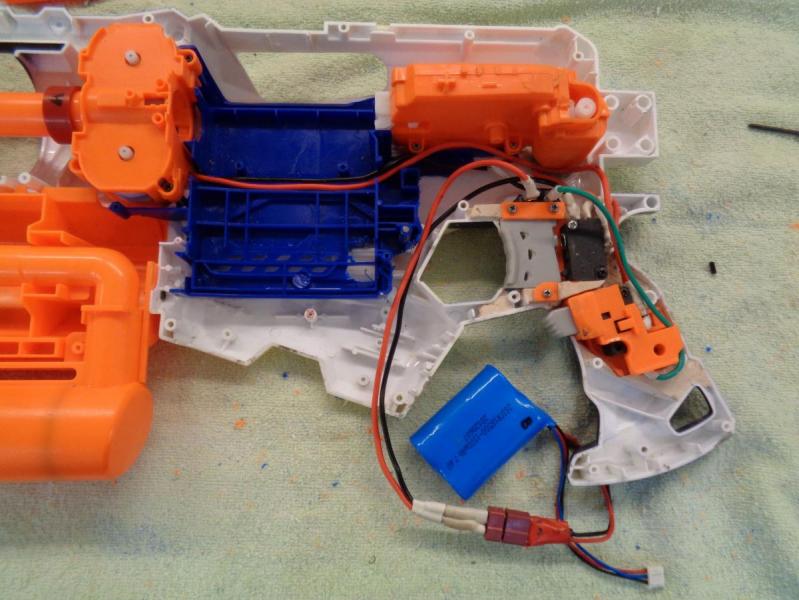

Semi-enclosed priming-arm pump-action Retaliator

[Retaliator body, Longstrike barrel, Scatterblast pump-grip, ø6.4mm 304 stainless steel welding rod pump-arms, AR intact, Tek-6 spring, Raider stock, "SleeperScope" fully-functional red dot sight.]

Imgur album for internal pics. (Sorry not really good enough detail to do a proper write-up yet...) Mod uses no additional screws or bolts though - it's entirely about the fit of the bent rod inside the shells.

Posted by

Posted by