- NerfHaven

- → zx532's Content

zx532's Content

There have been 178 items by zx532 (Search limited from 07-December 96)

#334083 3k Tank Issue

![]() Posted by

zx532

on 17 September 2013 - 01:09 PM

in

Modifications

Posted by

zx532

on 17 September 2013 - 01:09 PM

in

Modifications

(I mean one of the ones with a larger head that Nerf typically uses to hold extension springs in place)

#334082 3k Tank Issue

![]() Posted by

zx532

on 17 September 2013 - 01:08 PM

in

Modifications

Posted by

zx532

on 17 September 2013 - 01:08 PM

in

Modifications

(I mean one of the ones with a larger head that Nerf typically uses to hold extension springs in place)

#334077 3k Tank Issue

![]() Posted by

zx532

on 17 September 2013 - 07:34 AM

in

Modifications

Posted by

zx532

on 17 September 2013 - 07:34 AM

in

Modifications

#333238 RF20 powered Vulcan

![]() Posted by

zx532

on 19 August 2013 - 01:28 PM

in

Modifications

Posted by

zx532

on 19 August 2013 - 01:28 PM

in

Modifications

It is slower than an RF20, but faster than a Vulcan. The belt slows it down, and moving the belt rear seal also slows things down (because the seal has a return spring, that spring is also the reason for the pressure related problems)Does this thing fire as fast as a stock RF20, or does the belt advancement slow it down?

#333233 RF20 powered Vulcan

![]() Posted by

zx532

on 19 August 2013 - 11:52 AM

in

Modifications

Posted by

zx532

on 19 August 2013 - 11:52 AM

in

Modifications

Good idea, I'll be sure to try thatIt may help to sleeve 2 sections of 1 1/2" bike inner tube over the bladder. I had to do that to mine on my semi-auto DTG. Wow that was tough but worth the PSI boost. I had to lube the tubes with dish soap, ditch the stock clamps and put a base layer of e-tape down before switching to hose clamps (the inner tube was being crushed through the clamp slots without the e-tape). It boosted the pressure from 30ish psi to 45ish psi (if memory serves). It will help with pressure, but not capacity.

Just make sure you don't get a thorn proof inner-tube. They're thicker on the OD of the tube, thinner on the ID.

Capacity isn't really an issue, it's pressure. The RF20 bladder clearly has the capacity for 20+ shots)

I just need to increase the pressure on that amount of air. And I'm sure that this isn't quite how pneumatics work, bit it's a step in the right direction.

#333224 RF20 powered Vulcan

![]() Posted by

zx532

on 19 August 2013 - 07:48 AM

in

Modifications

Posted by

zx532

on 19 August 2013 - 07:48 AM

in

Modifications

Ahh, that makes sense nowVolume is certainly one of the most important. The only bonus a smaller ID gives is that its easier for them to reach higher pressures at the cost of volume. You trade volume for potential psi as you get smaller. It's pneumatics. If you can fully pump your rf20 bladder without being fatigued I'd keep the pump you have.

Any chance we could see a firing vid? I'd love to see it working.

As far as the firing vid, there will be one, eventually right now it only fires a few times before stopping (RF20 bladder can't hold enough pressure for long enough) so I'm working on it, and will get back to you with that

#333222 RF20 powered Vulcan

![]() Posted by

zx532

on 19 August 2013 - 06:31 AM

in

Modifications

Posted by

zx532

on 19 August 2013 - 06:31 AM

in

Modifications

Ever tried reloading an RF20? It's called 20 because that's how long it takesI love it man.

Where and how did you come up with this idea?

That makes no sense to me, isn't volume the only important factor when referring to performance of a pump?Have you tried this with a lower ID pump? (such as a magstrike pump)? Larger pumps are better for volume, but don't work as well when the area being filled is less.

#333218 RF20 powered Vulcan

![]() Posted by

zx532

on 19 August 2013 - 12:09 AM

in

Modifications

Posted by

zx532

on 19 August 2013 - 12:09 AM

in

Modifications

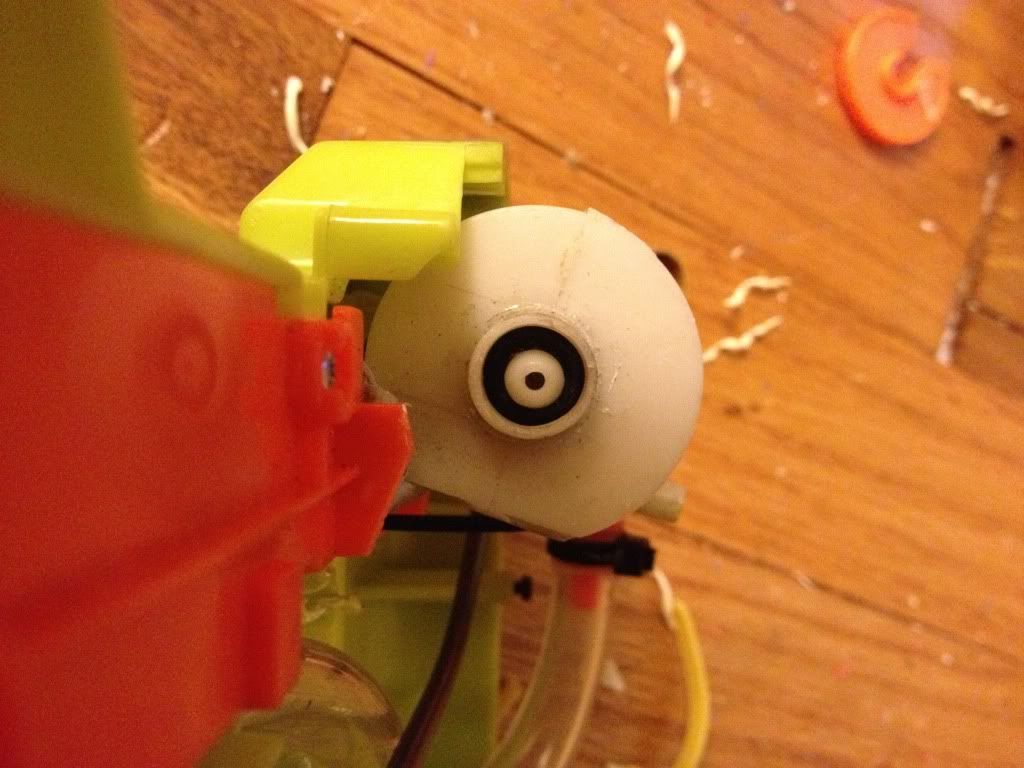

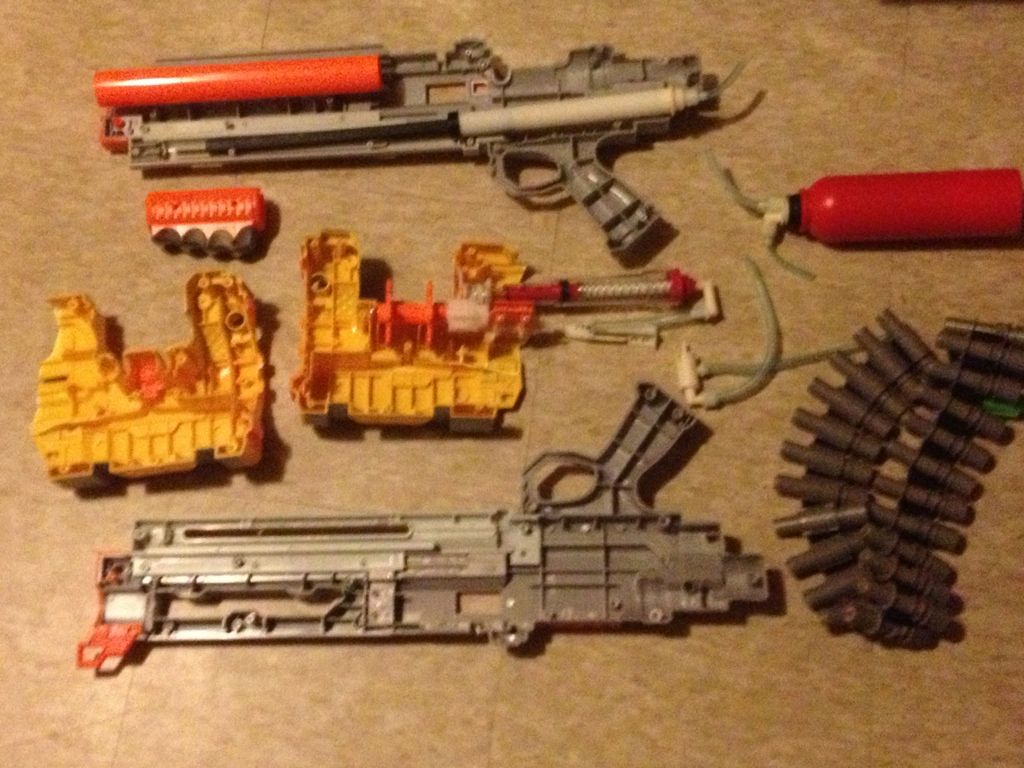

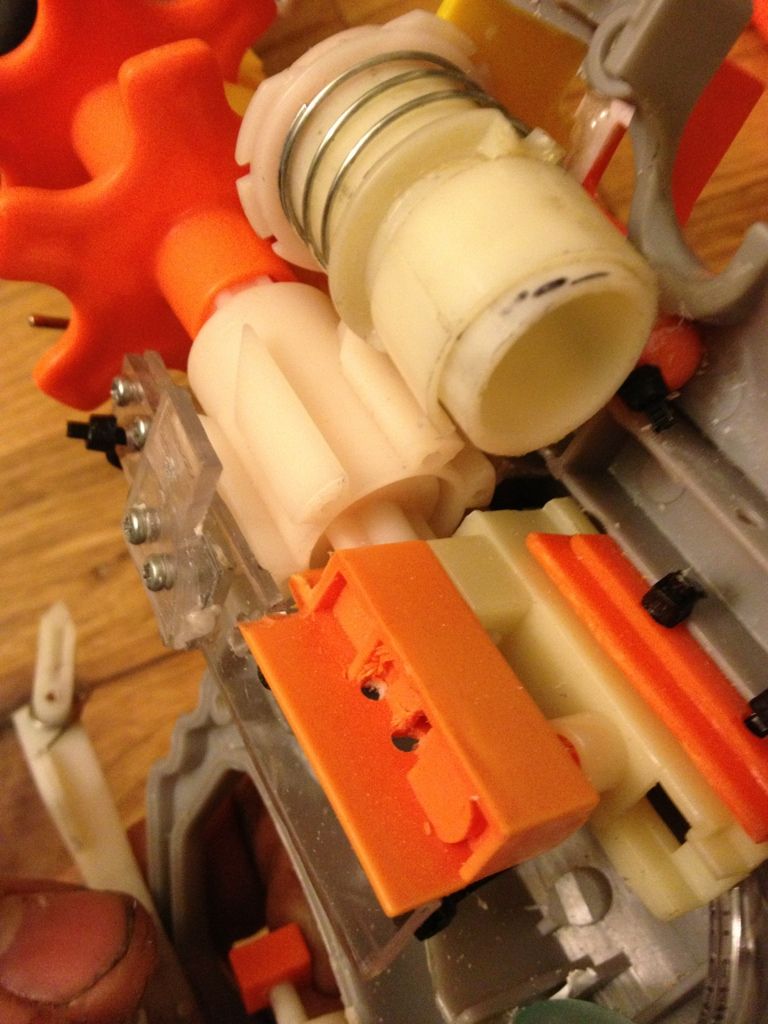

First a (probably incomplete) list of things used:

Shadow hawk shell

RF-20 (almost all of it)

Vulcan (the rotation mech, and associated shell pieces, and some other parts from other areas)

Zip ties (small and medium sized)

Random pieces of plastic/polycarb/whatever

Spare screws

Bell Airstrike 1000 pump, or whatever your pump of choice is (not pictured above)

Some nuts, bolts, and washers

Plastic welder (the epoxy stuff)

Tools, lots of them

First the shell:

The shadow hawk shell is actually made of more rigid plastic than most Nerf brand blasters, it is also assembled in sections (each half is actually six pieces) this is both easier to work with because you don’t have to deal with the whole thing at once, and a pain because a lot of material has to be removed from certain areas, and the thing still has to hold together, lots of screw ports will be omitted.

The only parts of the Vulcan shell needed are the barrel insert, and the area where the chain goes. You don’t want the front wall, but the back one is very important for lining things up (more on that later)

the front part of the Shadow hawk shell gets lots of attention from the Dremel. Its original bore is around .25 inches, and the Vulcan barrel is a lot closer to 1.5 inches, so go crazy, but make sure it is straight. To accommodate your hand pump of choice, just cut the existing pump grip slide out (I left a part of the stop from the original grip on for aesthetic purposes.)

For the middle part of the shell, all you have to do is cut a section out of the shell wide enough to fit the part of the shell from the Vulcan. When epoxying this in place however, it is crucial that it is centered as perfectly as possible (I mechanically fastened it with zip ties and then used the epoxy, just to be sure). I attached pieces from the front of the Vulcan for structural reasons (also because I thought that they looked cool)

The rear section is relatively simple, some holes need to be drilled for air lines, and the space around where the RF-20 piston needs to move needs to be cleared up (you will probably have to go back and clear some more out later, I had to go back in there three or four times due to the piston rubbing on things and wasting energy

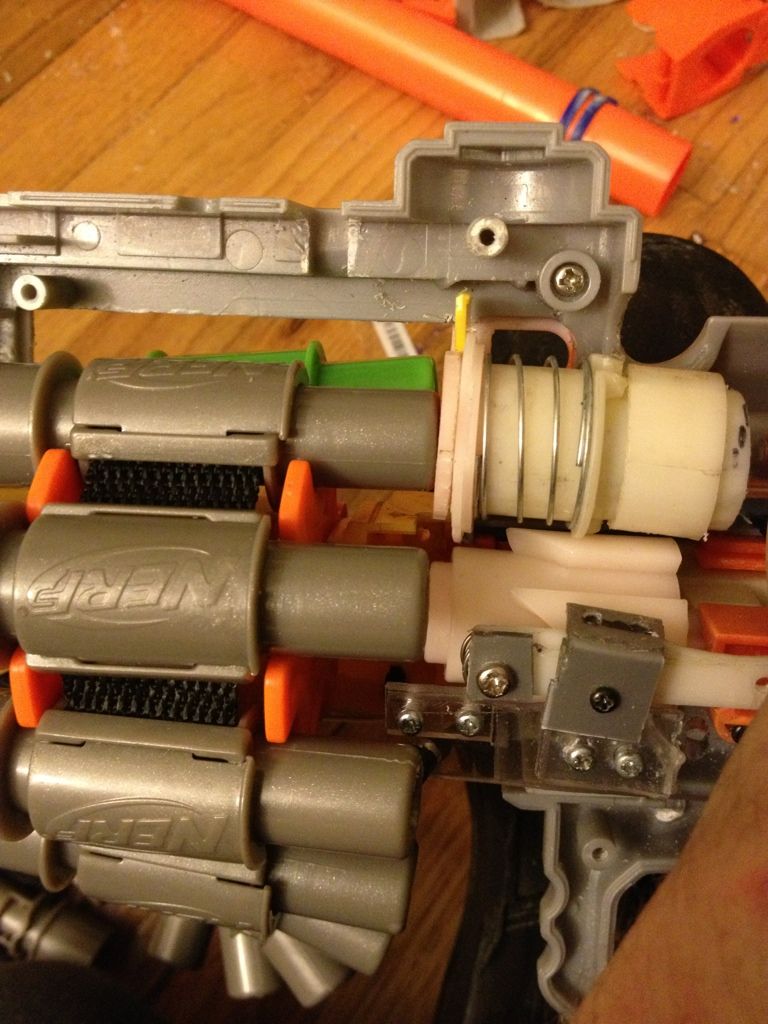

Next for the piston and related parts (pretty much everything but the rotation mechanism)

This is also around the point where documentation and specific dimensions is almost nonexistent (not that there has been much of it up to this point) so I apologize for that

The piston is secured to the rearmost part of the Shadow hawk shell (as it turns out it is the same thickness as the gap in the mount on the back of the piston)

when supplied with air (using the stock RF20 trigger valve)

It moves forward until it meets up with and then pushes the part that seals against the Vulcan chain. The front RF20 seal has been super glued to the back of it, and part of the Vulcan plunger tube has been used to prevent the return spring from pulling the whole assembly out (another part of the plunger tube has been used as a guide)

And now for the rotation mech:

First off the stock mech in the Vulcan was actually broken in the one I found at the thrift store and the RF20 is a push-type rotation mechanism whereas the Vulcan is a pull-type. Anyone who has used a maverick will tell you how unreliable it is when the firing chamber advances at the same time as firing, so I had to start completely from scratch. The other important thing here is the location of the part that actually does the pulling, it has to be on the side in the same place as the Vulcan otherwise the rest state of the Vulcan belt won’t be lined up with the barrel and piston (and it won’t fire). Since this is the only part being attached to the Shadow hawk shell, I just made fine adjustments on the angle with zip ties so the belt sat in the correct place.

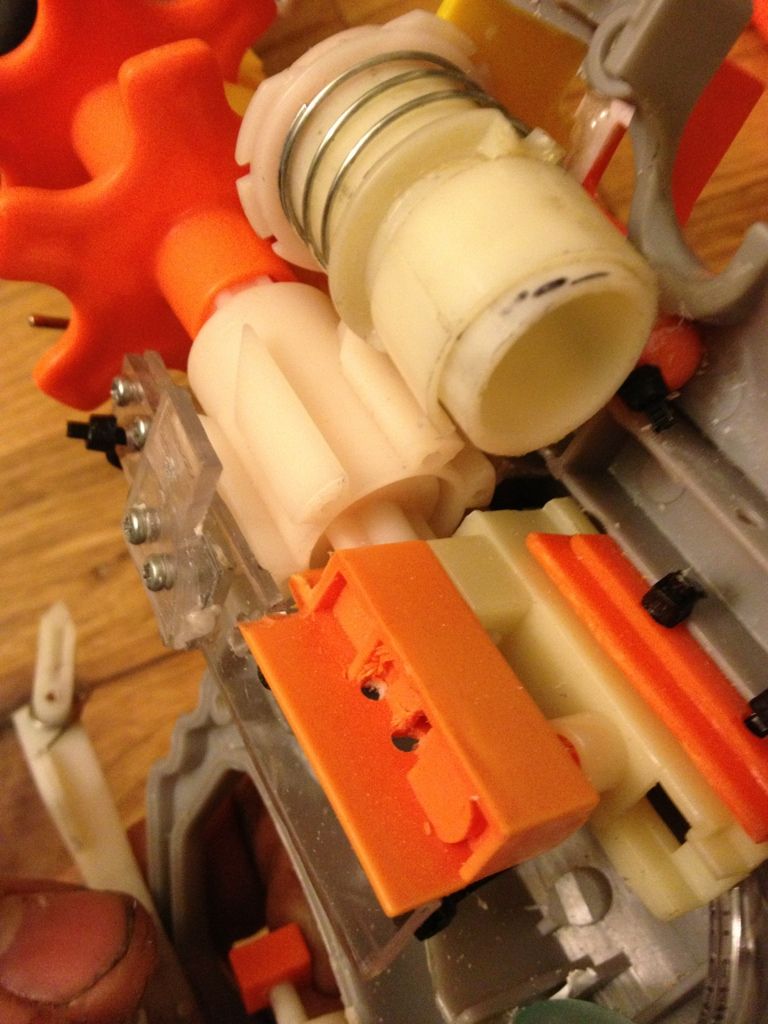

To get the spacing right between the rotation mech tab on the piston (which needs to be trimmed a bit to allow for full travel) and where the puller arm is just used a bolt, some washers and some nuts. That way it can be finely tuned and adjusted, when you get it right, use some blue or red Loctite on the threads to prevent the nuts from moving.

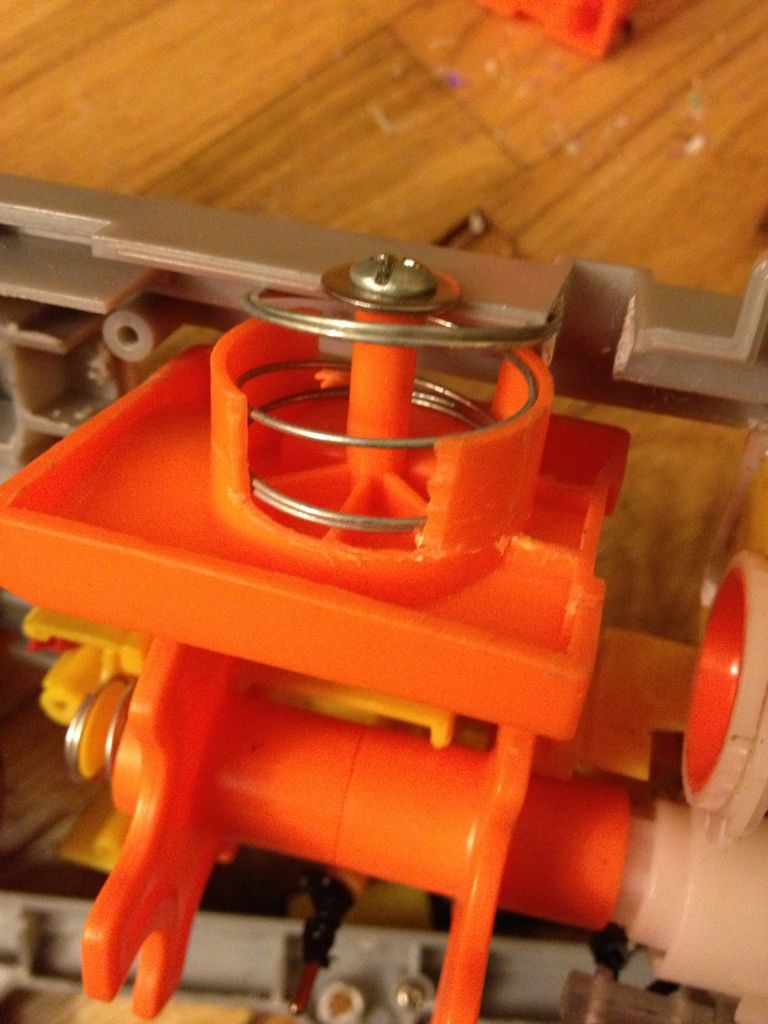

The other important part of the rotation mech is the chain tensioner (that little spring loaded piece in the big orange part that goes over the Vulcan chain) I just screwed a bolt and washer down through the center piece, a small amount also needs to be trimmed from the sides of the spring retaining circle just so that it fits in the Shadow hawk shell and can travel up and down freely. This part is important because it keeps pressure on the top of the chain so that it only moves when the rotation mech pulls on it (or when you are pulling it through)

I probably missed some stuff (as I have said before documentation wasn’t very good) if you have any questions, ask me. And if you want plans, PM me and I’ll get them to you when they exist.

Also I can’t get a firing video as of right now (or rather, I can, but you would only get a few shots before it stopped) the piston needs a higher pressure than the stock RF20 due to the fact that it is doing more things.

#332866 Retaliator/Recon carbine

![]() Posted by

zx532

on 10 August 2013 - 11:42 PM

in

Modifications

Posted by

zx532

on 10 August 2013 - 11:42 PM

in

Modifications

I have never heard of Recon boltsleds snapping, but longshot ones do all the time, especially if you only prime them on one side (Just something to think about).

#331248 Nerf Elite Mega Centurion - Preview and Internals

![]() Posted by

zx532

on 25 June 2013 - 01:35 AM

in

News

Posted by

zx532

on 25 June 2013 - 01:35 AM

in

News

#329244 Midwest Nerf Camping Weekend

![]() Posted by

zx532

on 01 May 2013 - 10:22 PM

in

Nerf Wars

Posted by

zx532

on 01 May 2013 - 10:22 PM

in

Nerf Wars

(Even if alcohol/similar things are banned outright, there will probably still be parents against it)

Has anything like this been done before?

#328486 Has anyone modded the Pyragon for firefly tech?

![]() Posted by

zx532

on 02 April 2013 - 12:28 AM

in

Modifications

Posted by

zx532

on 02 April 2013 - 12:28 AM

in

Modifications

I was thinking of doing something exactly like what you just posted, but I was wondering if, while using slamfire, the discs would be in the light long enough to charge up. Has anyone used this who can comment?

I don't know how long it takes to charge up the disks, but I know that the glow darts charge up pretty fast (they are still glowing pretty well while being shot out of a flywheel blaster rather quickly. Nerf probably uses similar chemicals in the darts and disks to achieve the glow, so Id imagine that it would be about the same.

#328301 Help with Nerf Deploy CS-6

![]() Posted by

zx532

on 24 March 2013 - 12:15 PM

in

General Nerf

Posted by

zx532

on 24 March 2013 - 12:15 PM

in

General Nerf

#327691 The BEST upgrade motor for the Stryfe (after extensive testing) is...

![]() Posted by

zx532

on 06 March 2013 - 08:46 AM

in

Modifications

Posted by

zx532

on 06 March 2013 - 08:46 AM

in

Modifications

#327439 Interesting function of the roughcut.

![]() Posted by

zx532

on 28 February 2013 - 10:52 AM

in

General Nerf

Posted by

zx532

on 28 February 2013 - 10:52 AM

in

General Nerf

This method will also work with the maverick (assuming the turret is lined up)

The nitefinder

Jolt

Possibly the strong arm

Basically any blaster that you load the dart into the barrel on

#327428 Interesting function of the roughcut.

![]() Posted by

zx532

on 28 February 2013 - 02:11 AM

in

General Nerf

Posted by

zx532

on 28 February 2013 - 02:11 AM

in

General Nerf

(unless I'm not reading something correctly)

#325129 firefly catch spring?

![]() Posted by

zx532

on 07 January 2013 - 07:34 PM

in

Modifications

Posted by

zx532

on 07 January 2013 - 07:34 PM

in

Modifications

Most times yes, but sometimes I also take a pair of needle nose pliers, grab each end of the spring, and twist them in opposite directions to expand the spring, and it works fine.

You could also shave the edges off the post a little bit with an xacto knife.

#324929 Dremel Recommendations

![]() Posted by

zx532

on 30 December 2012 - 05:04 PM

in

Modifications

Posted by

zx532

on 30 December 2012 - 05:04 PM

in

Modifications

as far as cutting disks these are what I use. I have heard that diamond disks are prone to shattering if you aren't cutting the right materials.

#324667 Direct-plunger Longstrike

![]() Posted by

zx532

on 22 December 2012 - 10:17 AM

in

Modifications

Posted by

zx532

on 22 December 2012 - 10:17 AM

in

Modifications

#324659 Direct-plunger Longstrike

![]() Posted by

zx532

on 21 December 2012 - 11:34 PM

in

Modifications

Posted by

zx532

on 21 December 2012 - 11:34 PM

in

Modifications

It is a recon, so it has to be adapted, but I actually did this with a longstrike, it's fairly simple.

(also, not entirely sure what the title was, but it was made by nine, or something like that. Might be a good place to start looking)

#324614 LS Priming Solution

![]() Posted by

zx532

on 19 December 2012 - 08:26 PM

in

Modifications

Posted by

zx532

on 19 December 2012 - 08:26 PM

in

Modifications

The point of this post is not a "You should do this" it is more of a "If this is annoying you, here is the solution"

#324595 LS Priming Solution

![]() Posted by

zx532

on 18 December 2012 - 11:13 PM

in

Modifications

Posted by

zx532

on 18 December 2012 - 11:13 PM

in

Modifications

If you want to keep the trigger lock (as I do), then doing this mod you will lose the trigger lock ability.

maybe so, however, as far as I can tell, if you leave the lock in the priming issue doesn't occur (granted, not much testing along those lines was done, so that could be entirely wrong)

#324590 LS Priming Solution

![]() Posted by

zx532

on 18 December 2012 - 09:19 PM

in

Modifications

Posted by

zx532

on 18 December 2012 - 09:19 PM

in

Modifications

I found a solution:

If you remove the boltsled lock, just cut the tail off of the boltsled. It isn't actually needed anymore

(I assume that this has been done before, but I didnt see it mentioned specifically in any of the Longshot posts)

#324435 Rampage priming issues

![]() Posted by

zx532

on 13 December 2012 - 09:06 AM

in

Modifications

Posted by

zx532

on 13 December 2012 - 09:06 AM

in

Modifications

(to rephrase, I know that the rampage has the lock, but it dosent look like the one in the raider based on the picture, so it may have been redesigned and is no longer a problem area)

#324172 Durability of Slug Darts

![]() Posted by

zx532

on 06 December 2012 - 10:42 AM

in

Darts and Barrels

Posted by

zx532

on 06 December 2012 - 10:42 AM

in

Darts and Barrels

Do you just glue the tips? Or do you drill into the foam with the hot glue gun?

Look in the darts forum for more info

#324146 How to make a longshot shell stop creaking?

![]() Posted by

zx532

on 05 December 2012 - 09:06 AM

in

Modifications

Posted by

zx532

on 05 December 2012 - 09:06 AM

in

Modifications

Also while it might expand out of some things, nerf plastic is very strong (it's high quality ABS plastic) compared to other types of plastic. The foam may squeeze itself out through some seams, but you can just cut it and trim it at that point.

#324109 XB-REV-001 (Custom Nerf Gunsmithing)

![]() Posted by

zx532

on 03 December 2012 - 01:21 PM

in

Homemades

Posted by

zx532

on 03 December 2012 - 01:21 PM

in

Homemades

All youd have to do is spin it around (and since youre already completely fabricating the shell it shouldn't be too hard

drill a hole in the back of the PT (now the front)

plug up the end of the plunger rod (as close to the o ring as possible)

you would have to make a special catch for it though

Also, like many others have previously said, amazing blaster design

#323941 Painting nerf guns with hvlp spray guns, and airbrushes

![]() Posted by

zx532

on 26 November 2012 - 01:57 PM

in

General Nerf

Posted by

zx532

on 26 November 2012 - 01:57 PM

in

General Nerf

Also, just to point out, not all paints are made for plastics, some of them don't bond very well with non-porous surfaces (like plastic)

#323913 How to fasten angel breech barrels.

![]() Posted by

zx532

on 25 November 2012 - 06:34 PM

in

Modifications

Posted by

zx532

on 25 November 2012 - 06:34 PM

in

Modifications

#323739 Broken Rapid Fire-20

![]() Posted by

zx532

on 19 November 2012 - 04:40 PM

in

Modifications

Posted by

zx532

on 19 November 2012 - 04:40 PM

in

Modifications

I have actually rebuilt a couple of these, if you need any help, feel free to PM me

#323675 Direct Propulsion Pistol

![]() Posted by

zx532

on 17 November 2012 - 04:08 PM

in

Homemades

Posted by

zx532

on 17 November 2012 - 04:08 PM

in

Homemades

The gun functions fine with two rubber bands, any more and the dart pusher goes flying.

In order to stop the dart pusher from flying into the front and damaging it, couldnt you have the opening at the back of the blaster instead of the front? you would still need to reinforce both sides, but the dart pusher would be hitting a solid part of the original material, instead of something cut and glued together.

#323602 Nerf Elite Pinpoint Sight

![]() Posted by

zx532

on 15 November 2012 - 10:31 AM

in

General Nerf

Posted by

zx532

on 15 November 2012 - 10:31 AM

in

General Nerf

#323551 Posting Pictures

![]() Posted by

zx532

on 14 November 2012 - 08:44 AM

in

Site Feedback

Posted by

zx532

on 14 November 2012 - 08:44 AM

in

Site Feedback

#323537 Death By Foam

![]() Posted by

zx532

on 13 November 2012 - 04:58 PM

in

Site Feedback

Posted by

zx532

on 13 November 2012 - 04:58 PM

in

Site Feedback

#323214 Hurricane Sandy

![]() Posted by

zx532

on 30 October 2012 - 05:41 PM

in

Off Topic

Posted by

zx532

on 30 October 2012 - 05:41 PM

in

Off Topic

but inland wasn't really anything, we did have school cancelled for two days though.

In all the storm that hit the Hartford area wasn't anywhere near as bad as the completely normal rain storm we had two weeks ago (just to put it in perspective)

#323190 pSyk's "Auto-Loading" Rampage 3k + Vid

![]() Posted by

zx532

on 29 October 2012 - 04:09 PM

in

Modifications

Posted by

zx532

on 29 October 2012 - 04:09 PM

in

Modifications

second, That is a genius lever trigger!

(in all, beautiful blaster)

#323189 Buzz Bee Cougar

![]() Posted by

zx532

on 29 October 2012 - 03:54 PM

in

Modifications

Posted by

zx532

on 29 October 2012 - 03:54 PM

in

Modifications

I see, I bet some cpvc would work better then.

Actually, hamoidar is right, the barrels themselves are too close together for CPVC to fit

#323167 Buzz Bee Cougar

![]() Posted by

zx532

on 29 October 2012 - 10:37 AM

in

Modifications

Posted by

zx532

on 29 October 2012 - 10:37 AM

in

Modifications

I see, I bet some cpvc would work better then.

I was going to look into PETG (but that's less because it might be the best choice, and more because I haven't done a PETG barrel yet)

- NerfHaven

- → zx532's Content

- Terms of Service and Privacy Policy

- Code of Conduct ·