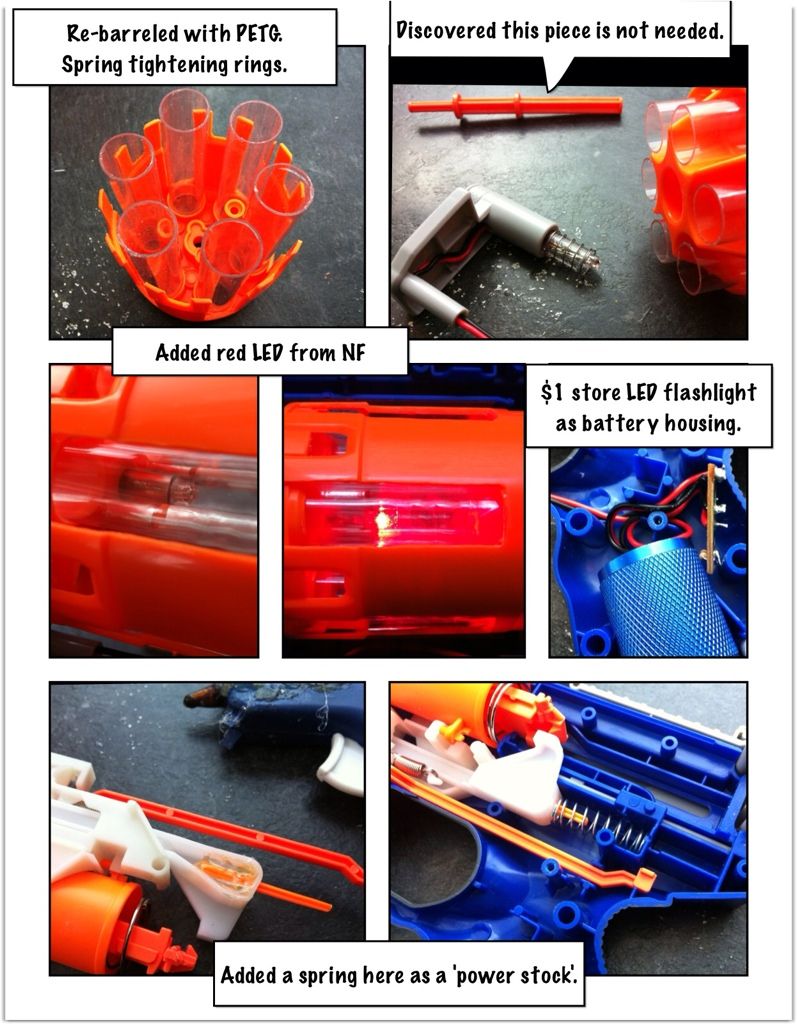

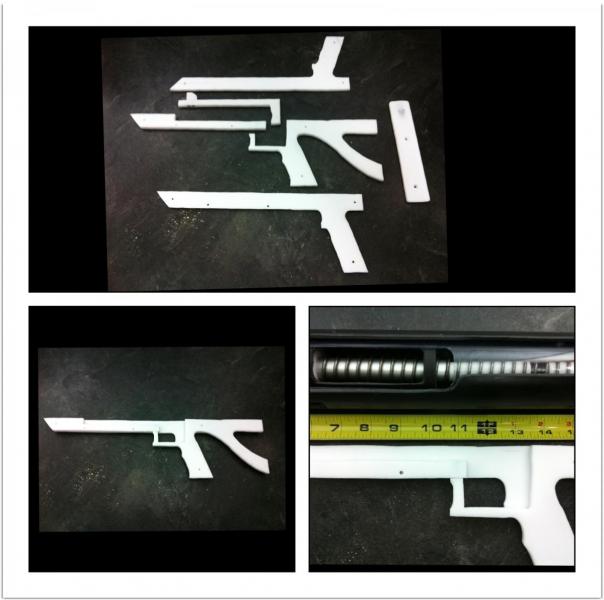

Unprimed

Half prime

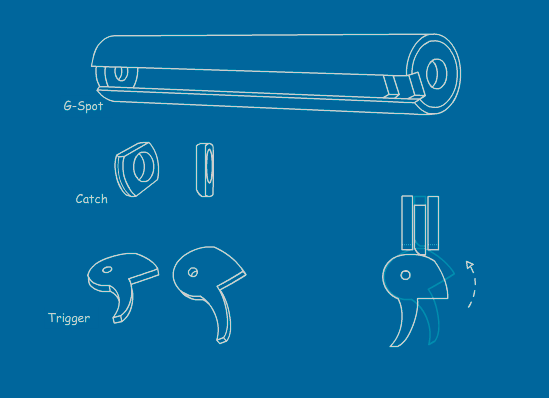

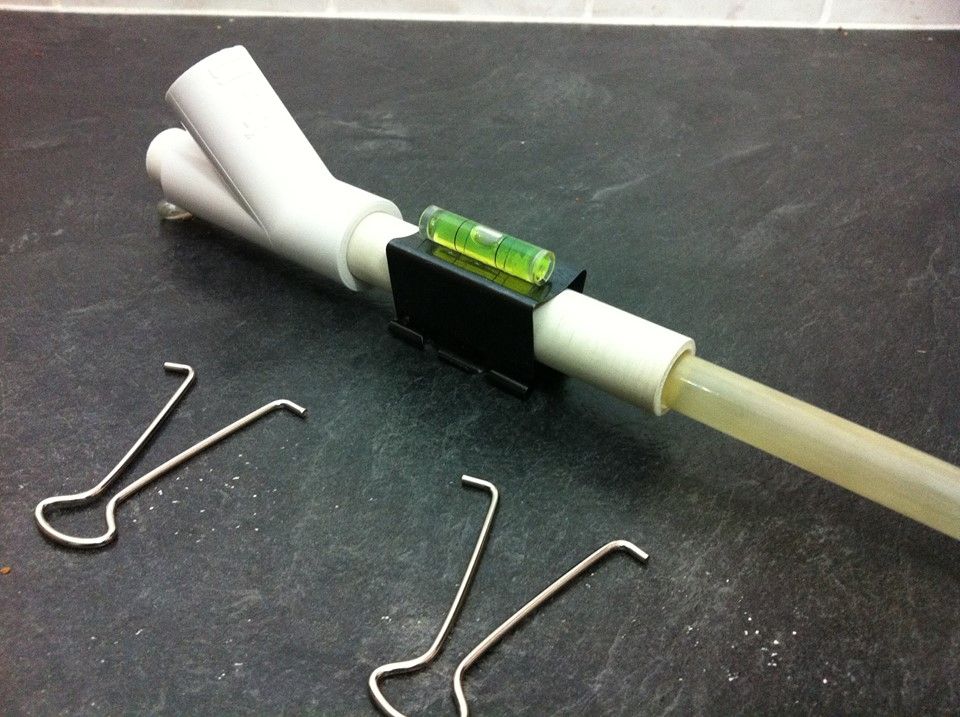

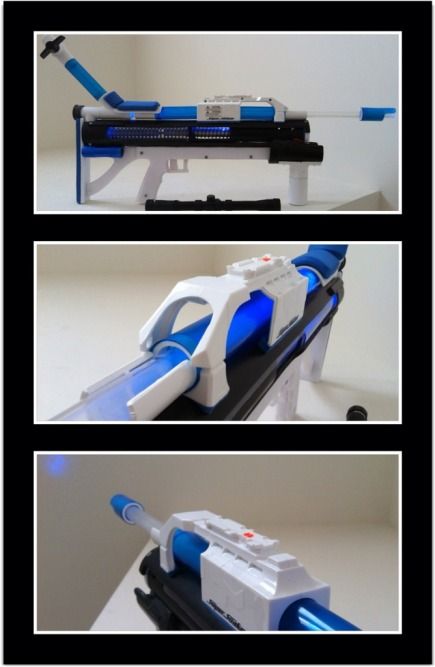

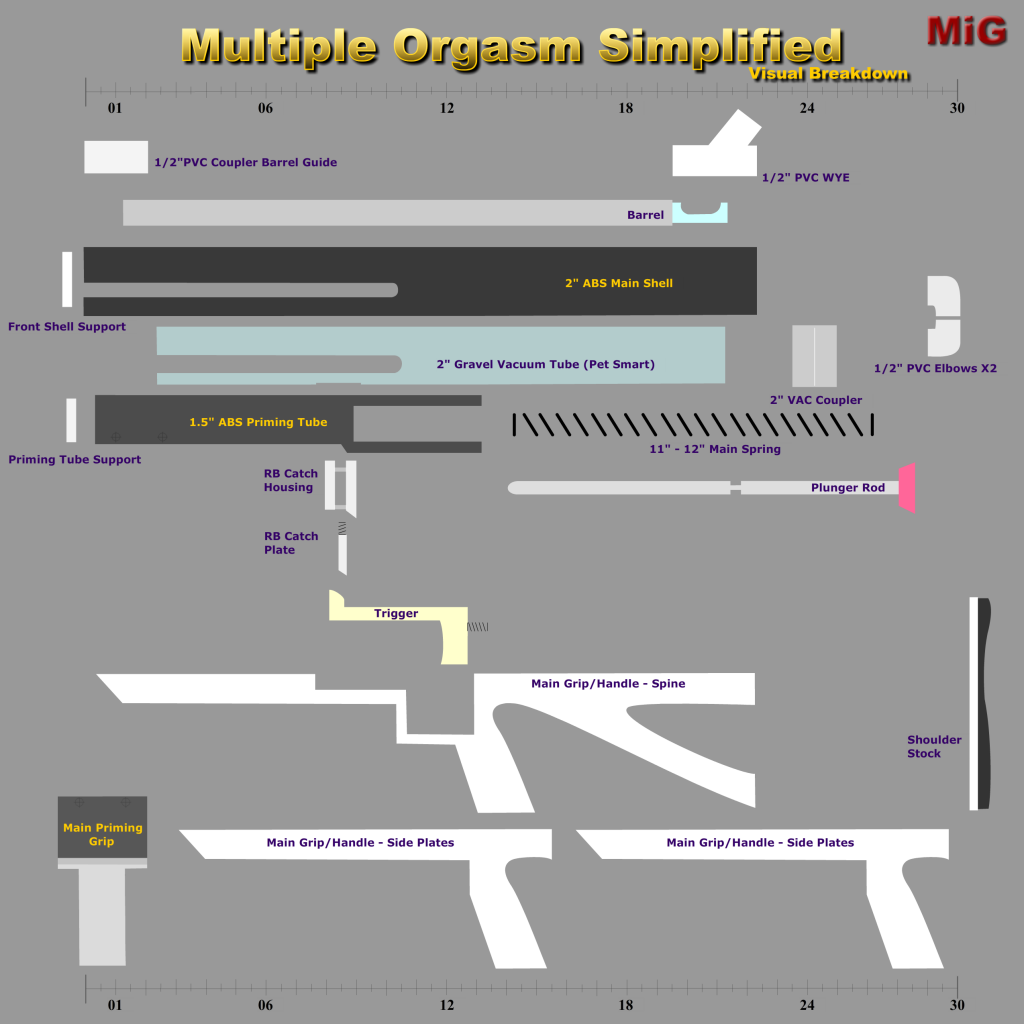

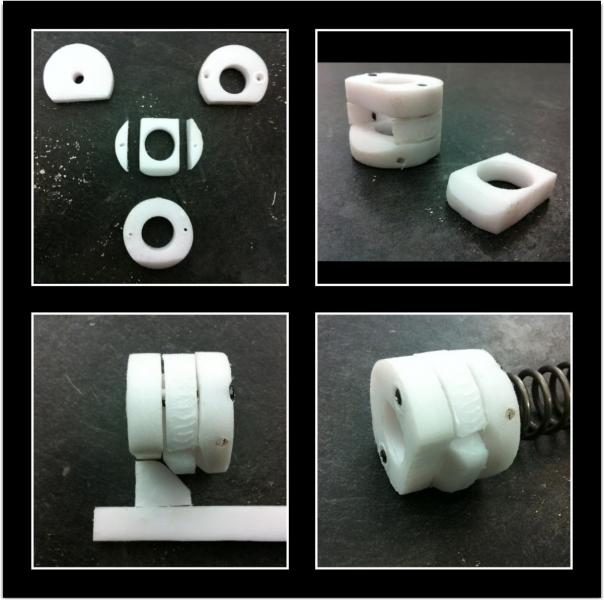

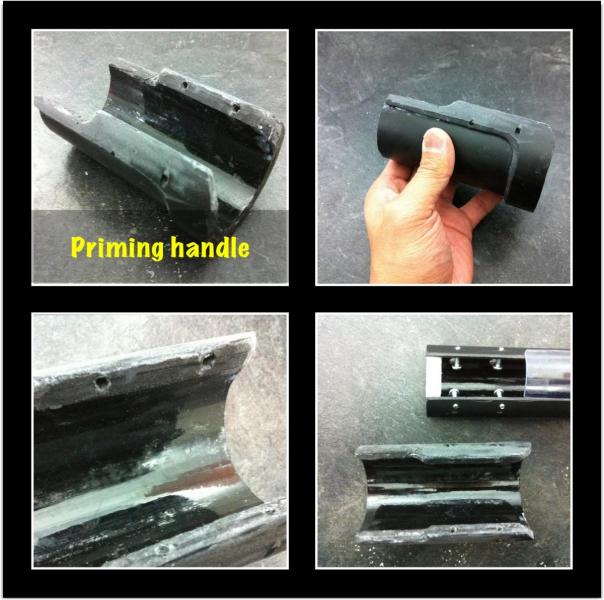

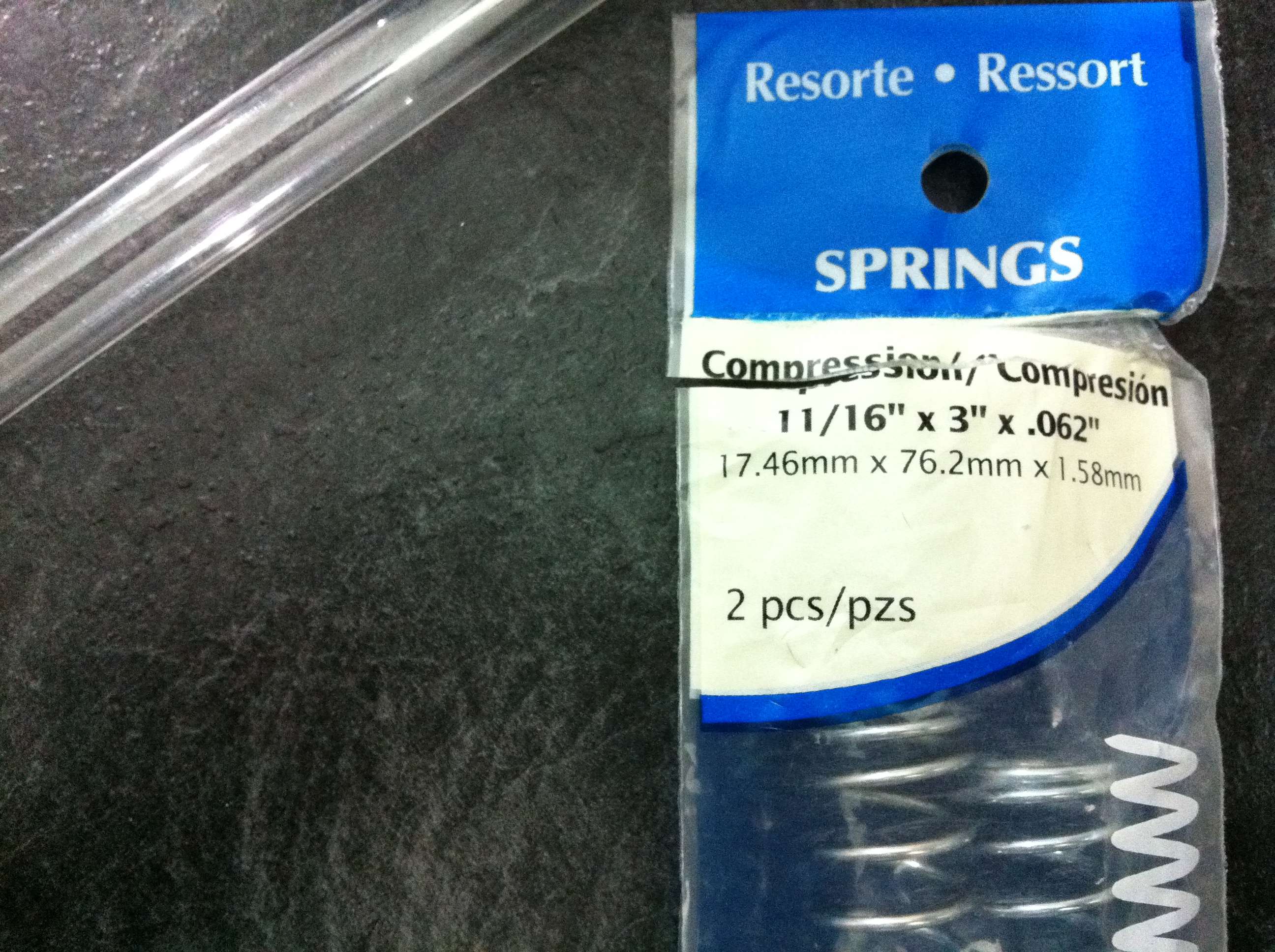

Still a WIP. My latest endeavor/prototype. Inspired by the Mountain bike forks above (I mountain bike - Downhill/Enduro). Obviously, much tweaking and testing still needs to be done. Nothing has been 'set' as I'm leaving it with the ability to dismantle it for the eventual write-up.

Posted by

Posted by