And I do also want to figure out some sort of long range integration. Just haven't decided what exactly to go with yet for that. Any ideas?

The magstrike runs entire on air pressure, there is no spring system in it. If I wanted to increase the power and rate of fire I can just increase the air pressure from the regulator. I keep it down though so that it is reasonable enough to pass HvZ rules. =)

Actually the magstrike is a hybrid between pump and springer powered. The air reserve tank actuates a spring powered piston and the spring piston actually delivers the air to the dart. Increasing the air pressure increases ROF, increasing spring strength increases range. It's an odd relationship. With all you've invested in your setup a basic spring swap would be worth looking into.

As far as long range options:

A pin pull tank would give you the most volume and range (like a early gen BBBB or beserker ~100'-120') but you would be bleeding your reserve tank out your barrel as long as the pin remained pulled. You could overcome that with a quick trigger pull, but that may require more thought than you would like to invest while in battle.

A back pressure tank would give you ~ 70'-90' & require a clippard MAVO-3 valve (buy from ebay not clippard. Clippard shipping costs are brutal)to isolate the reserve tank and fire your primary. All the current semi auto write ups are tuned to a turret which sucks for reloading. If you don't mind doing some R&D you could easily adapt it to a single shot breech loading system. If you really wanted to get crazy with it you could run with an idea I was working with but had abandoned:

it's a video - click the link.

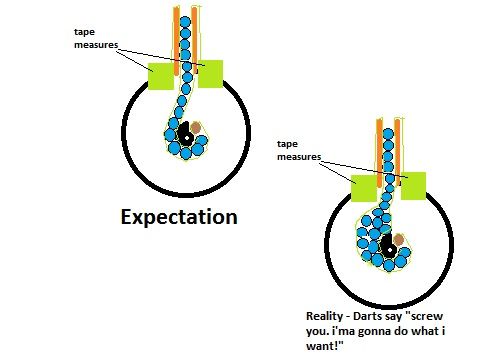

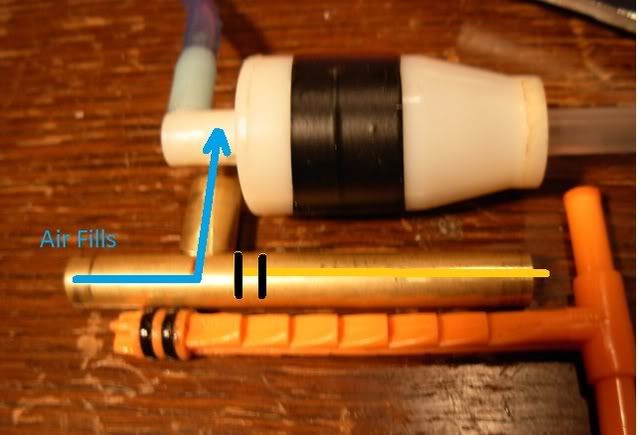

The basic concept is that a piston (in this case a pump) is attached to the side of a back pressure tank and when the tank fills the piston fills from the tank and extends loading a dart while closing the breech. When the tank fires the piston/pump also vents back through the back pressure tank opening the breech for the next dart. Semi-auto clip fed goodness. My problems - the throw of the piston was too short and the breech didn't seal. I think the breech also started opening before the dart had left the barrel. Connecting the piston via some tubing instead of directly might introduce of introduced a bit of delay as the piston vents through the tube and back into the tank. I got proof of concept, but not much else. You might have better luck. A self loading system like that might be better suited to your high capacity rig anyway.

Posted by

Posted by