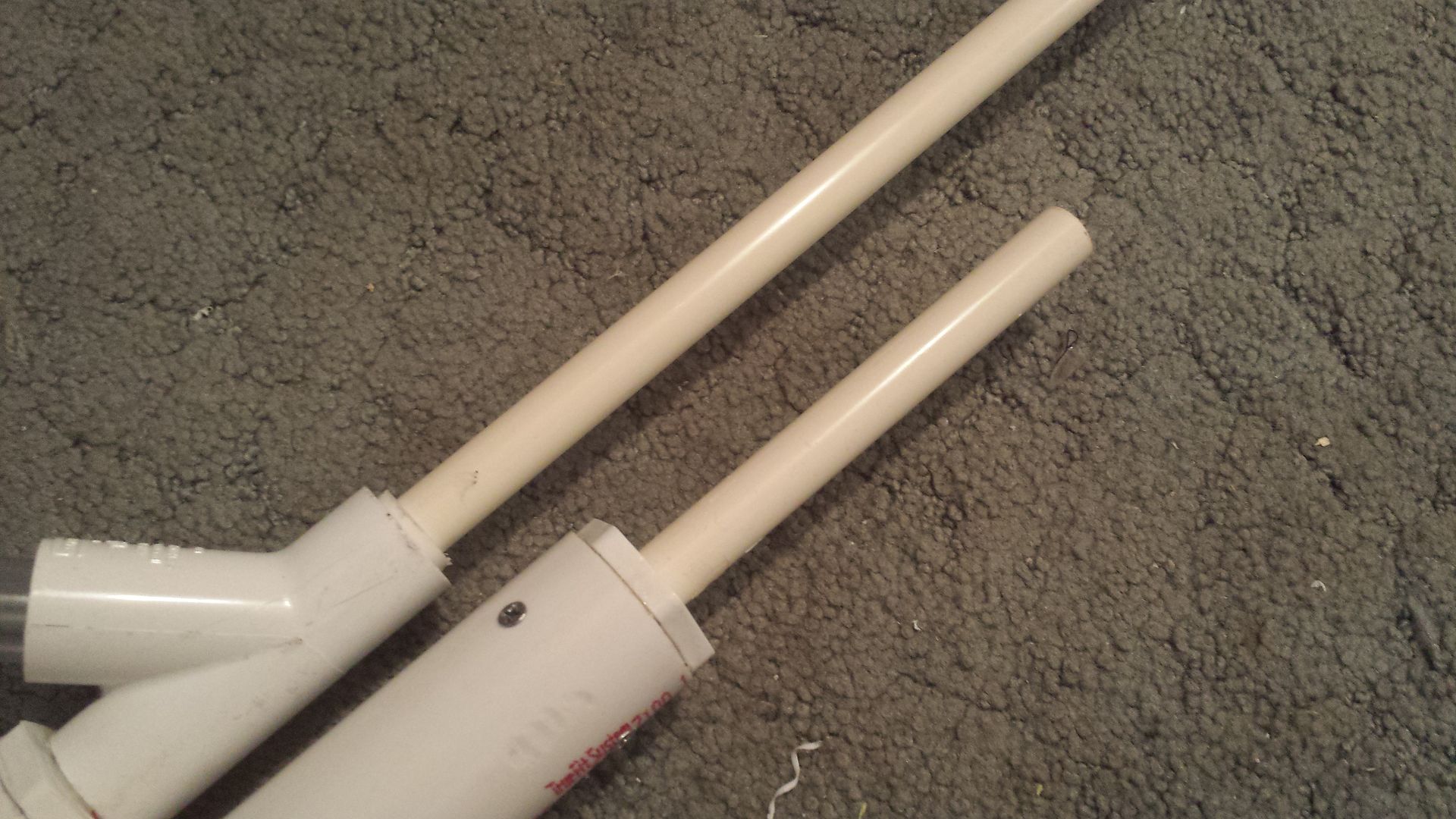

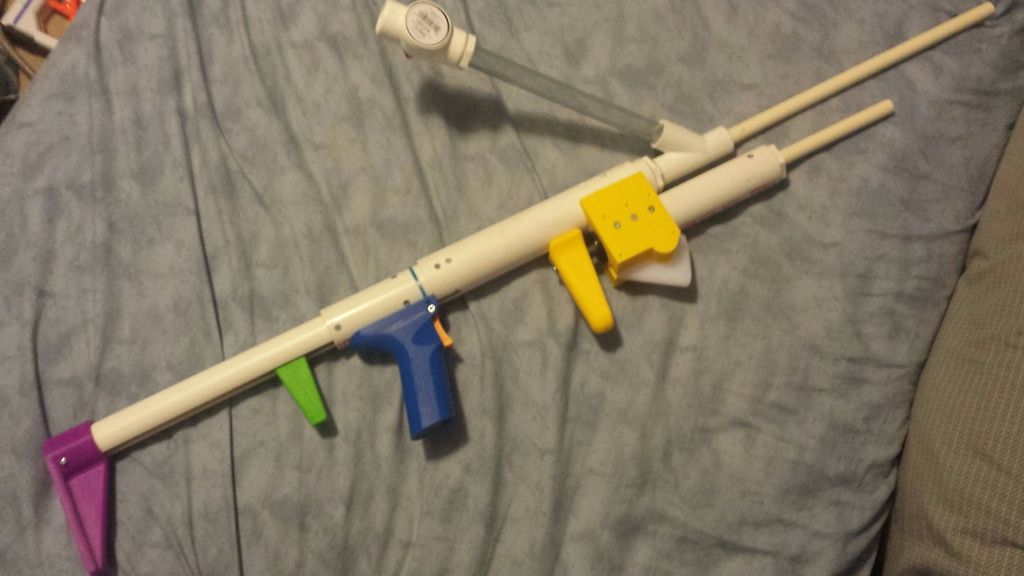

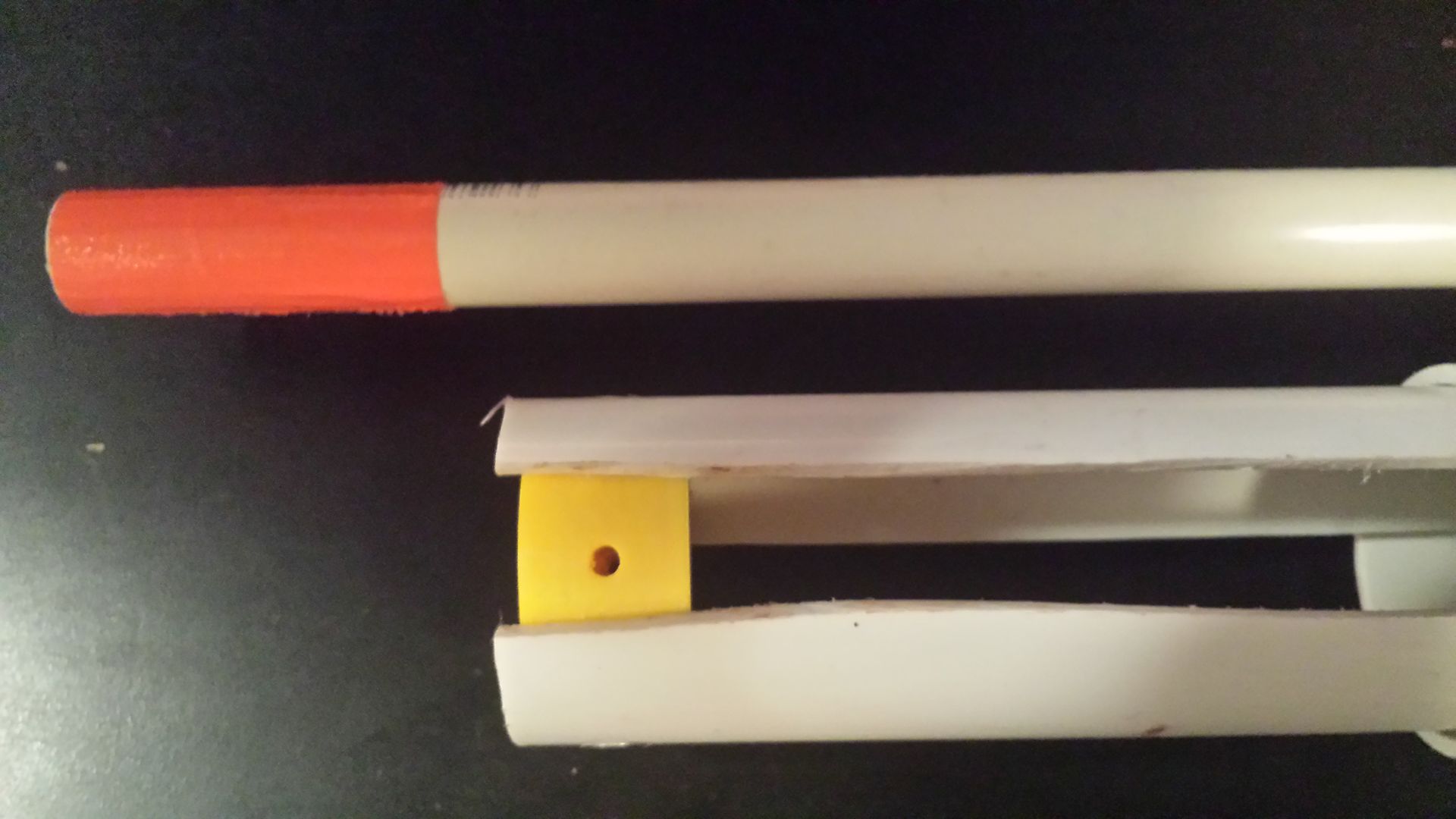

Good work. So simple I don't know why no one has done it before. I would've underslung an airgun, but there's no nothing wrong with a RBPistol. Only issue I can see is sourcing the thinwall pipe, which from what I remember is difficult to find.

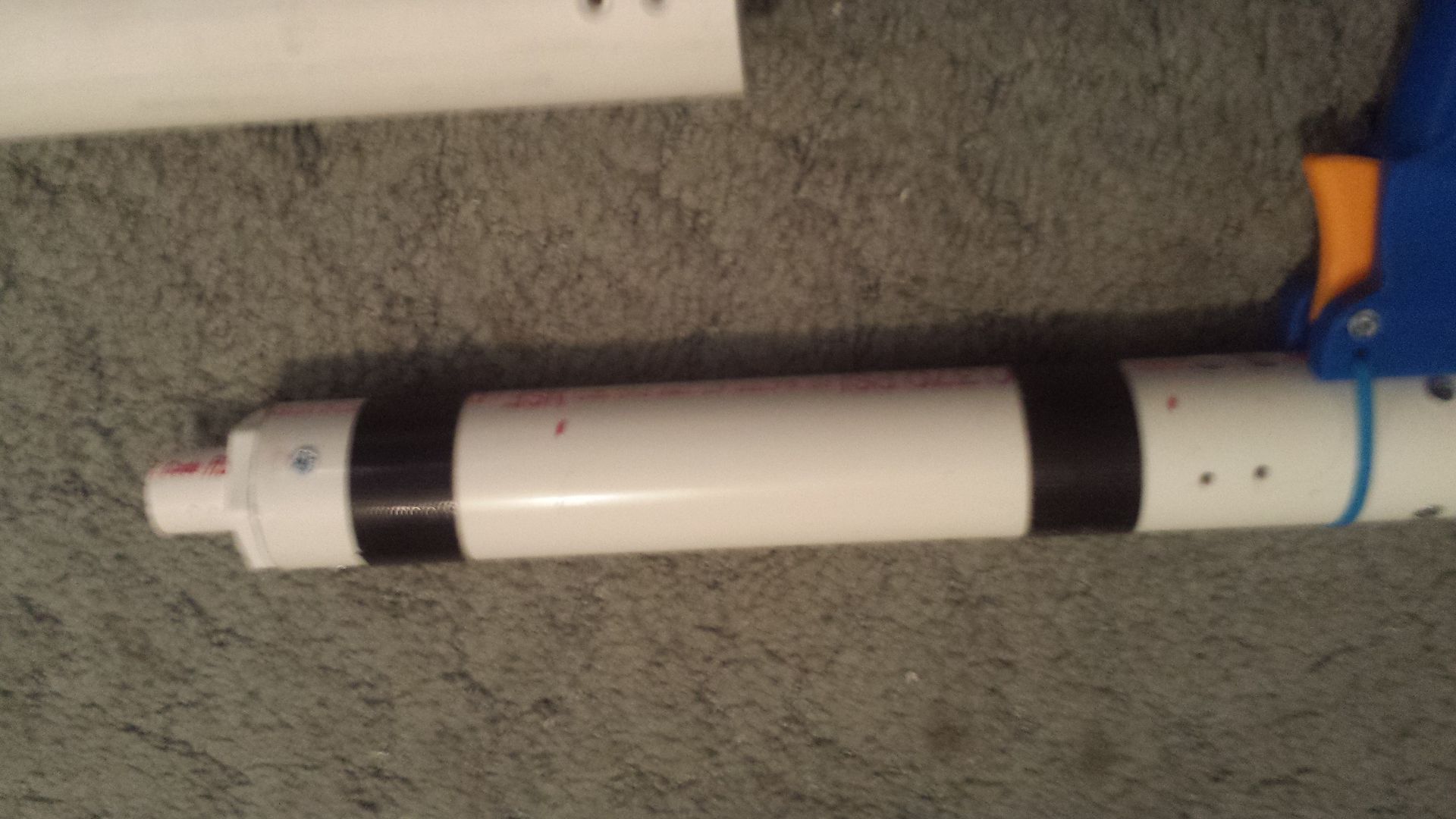

Everyone seems to find it in their local hardware stores, but I just buy it online because it's never available in my vicinity.

Not sure if it'll help Canadians, but you can buy it hereand pick up in store, if you're fortunate enough to live near a DoItBest.

Nice job on this Aeromech, I would be nervous about the thinwall cracking around the screws, but since it's holding up for you I guess I'm just underestimating PVC.

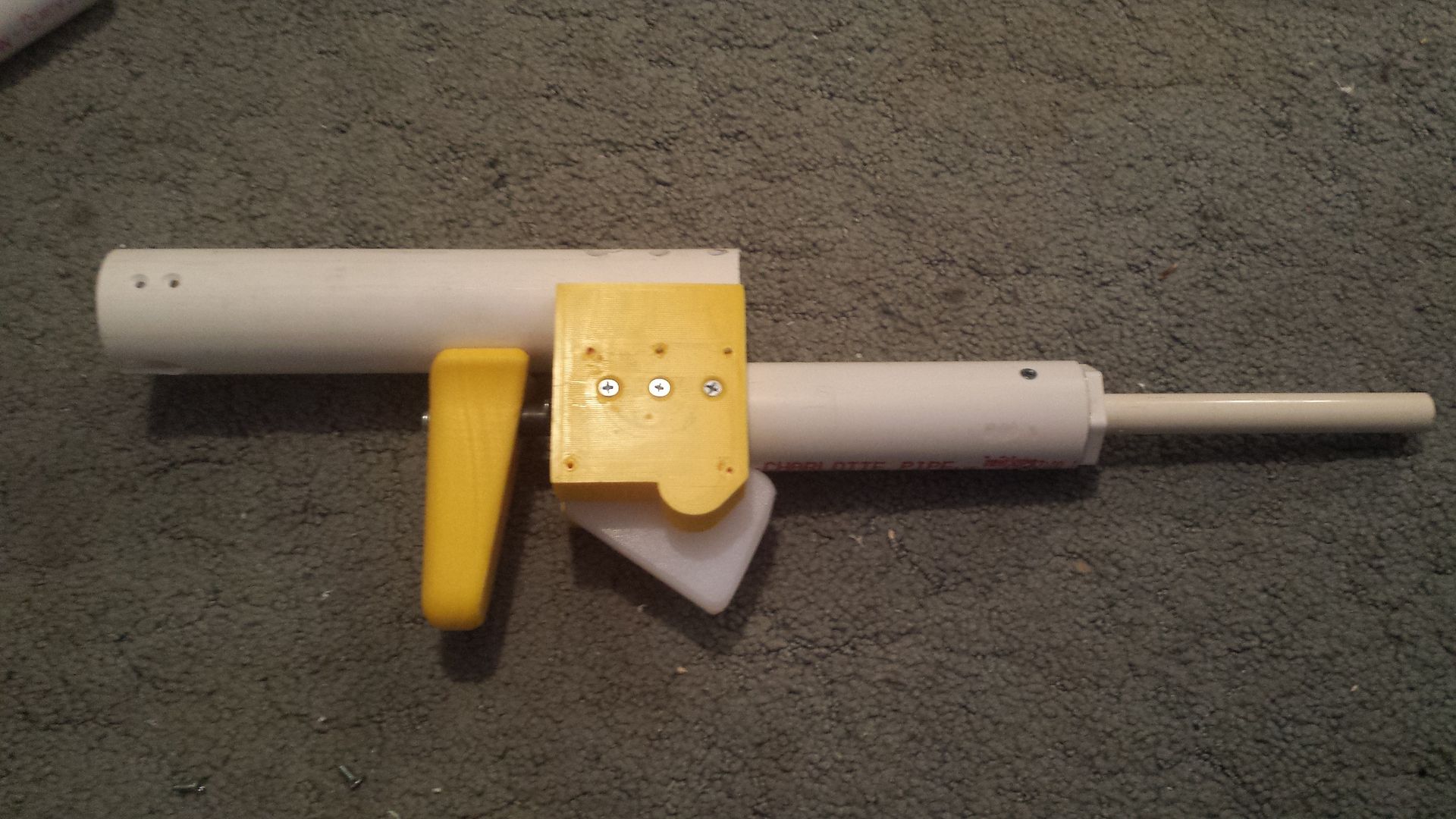

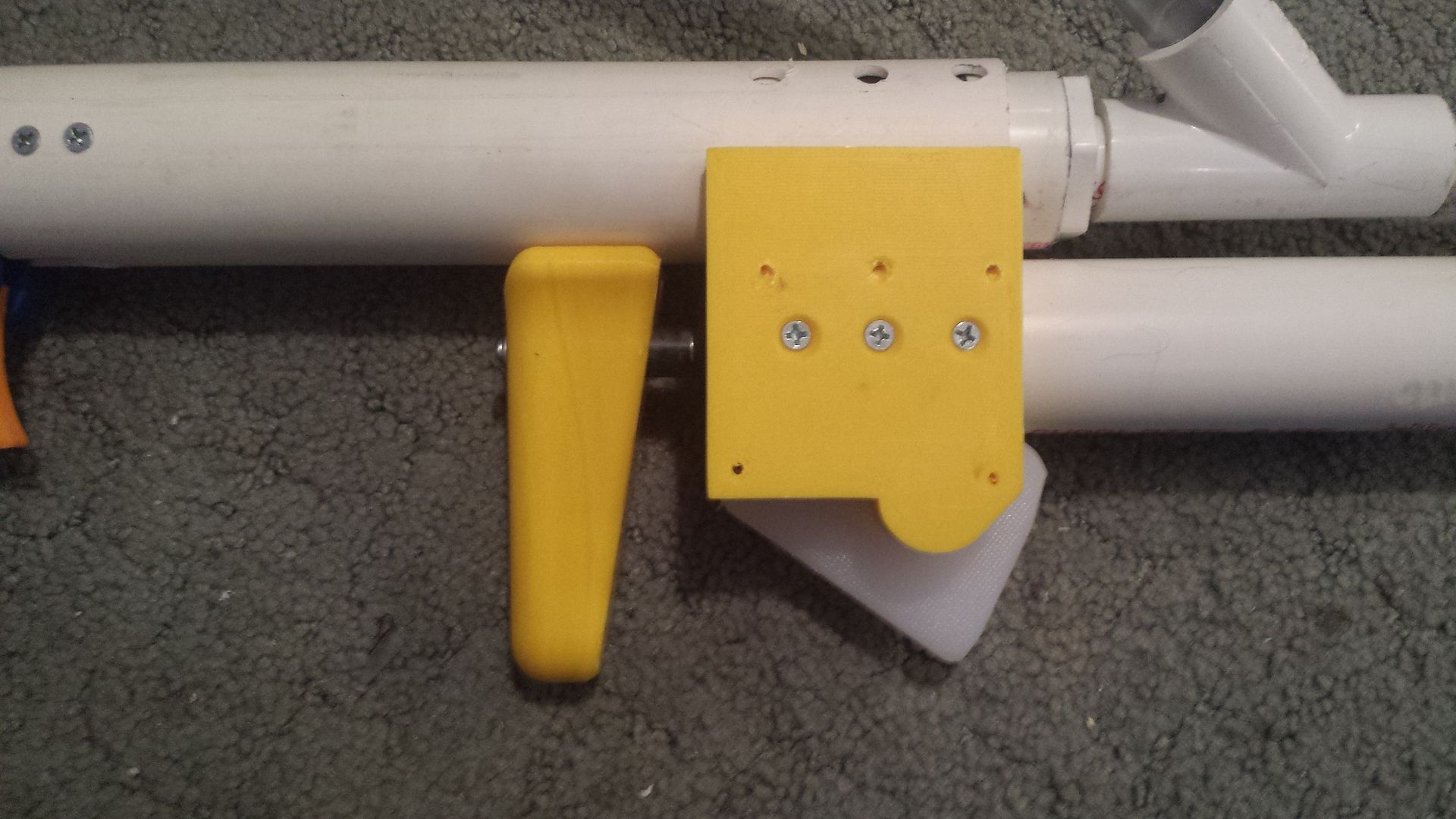

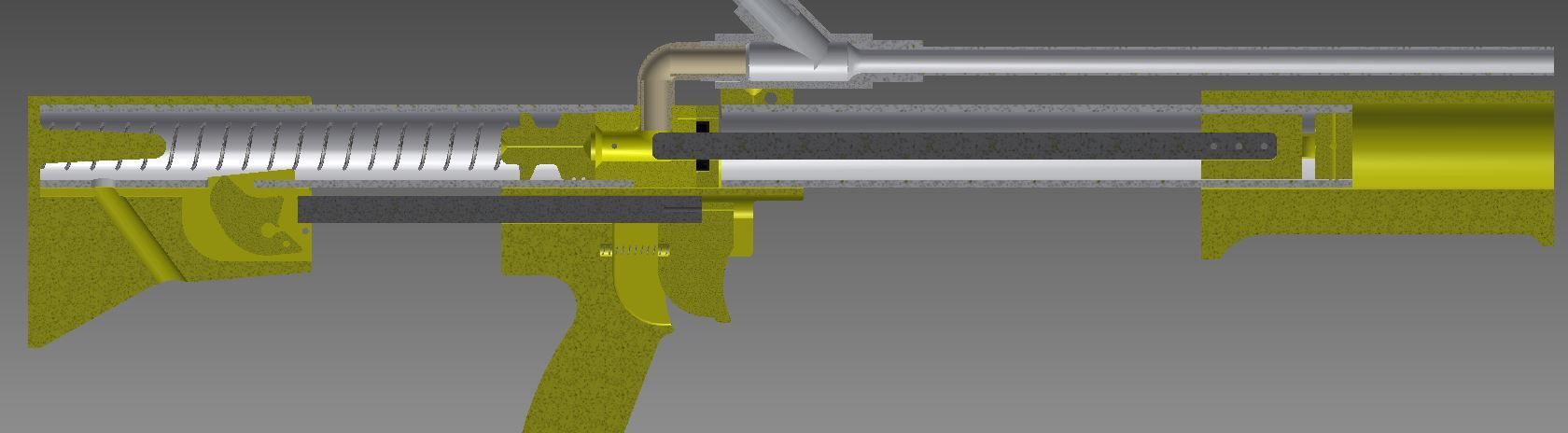

You said that the palm-trigger takes some getting used to, and it looks like it. I'm not a fan of vertical foregrips, but maybe you could have the pistol's priming grip return forward after priming. Reshape it into a vertical foregrip and then you could put a more "normal" trigger on the pistol.

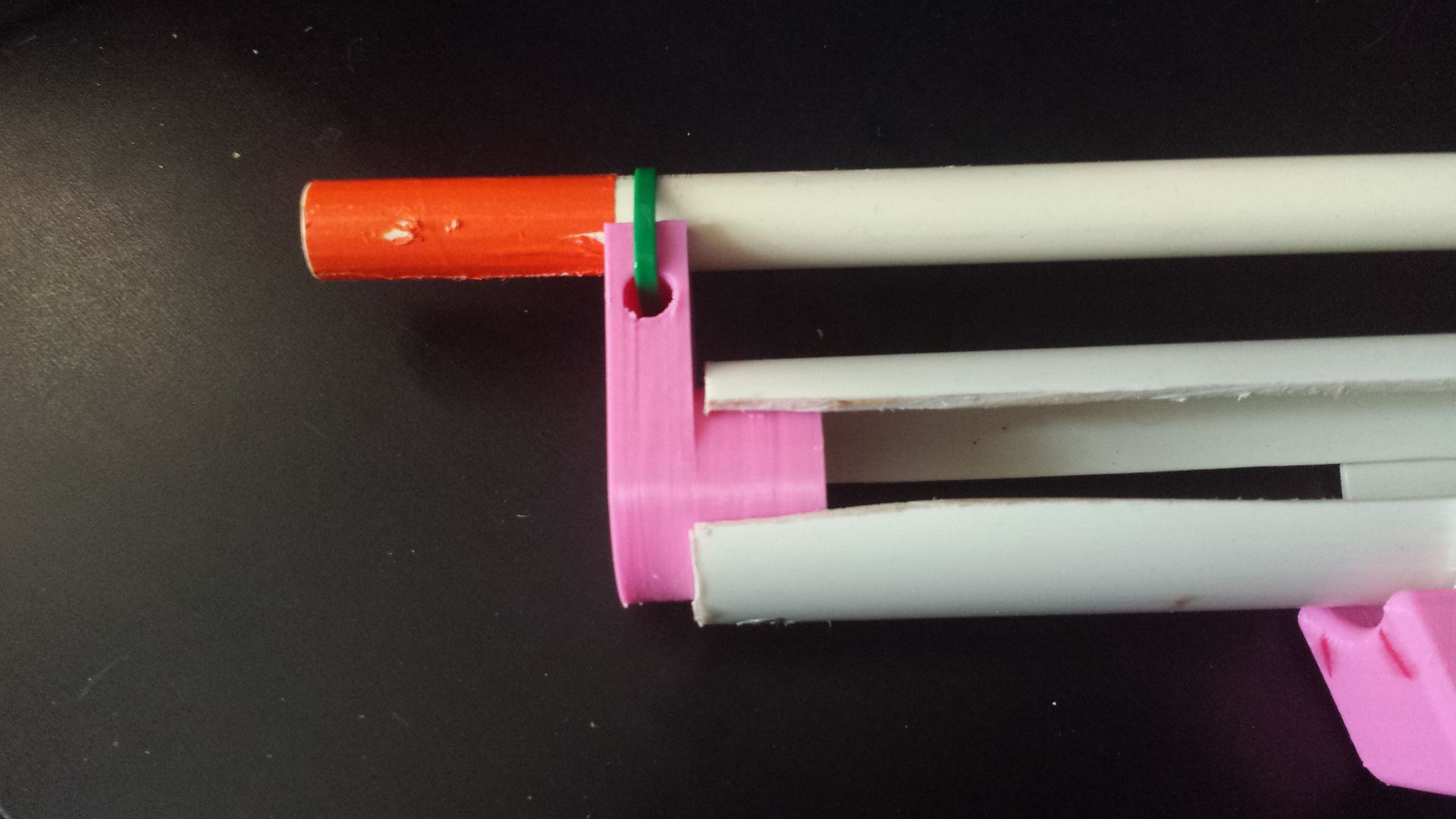

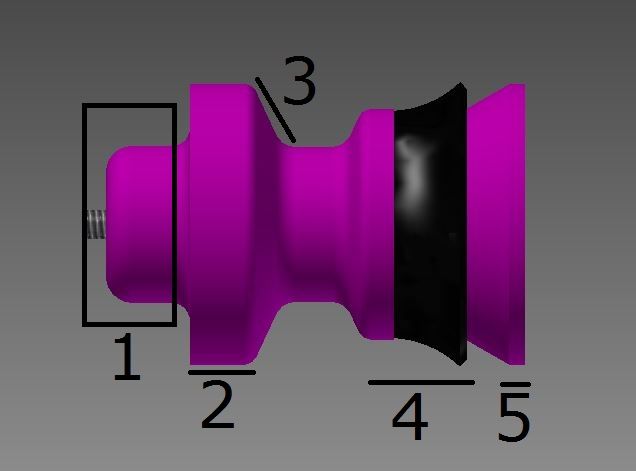

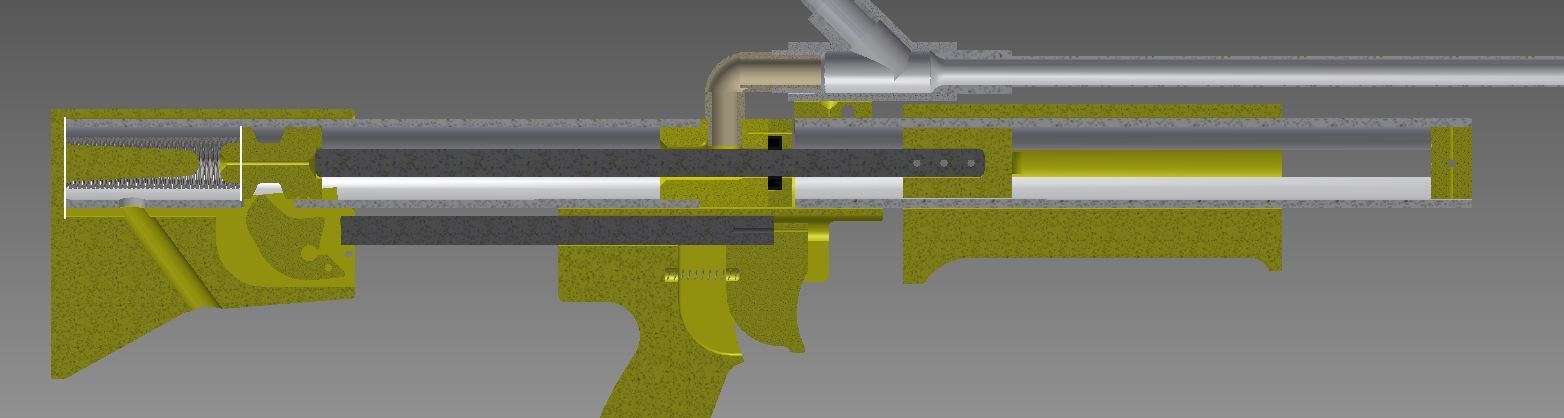

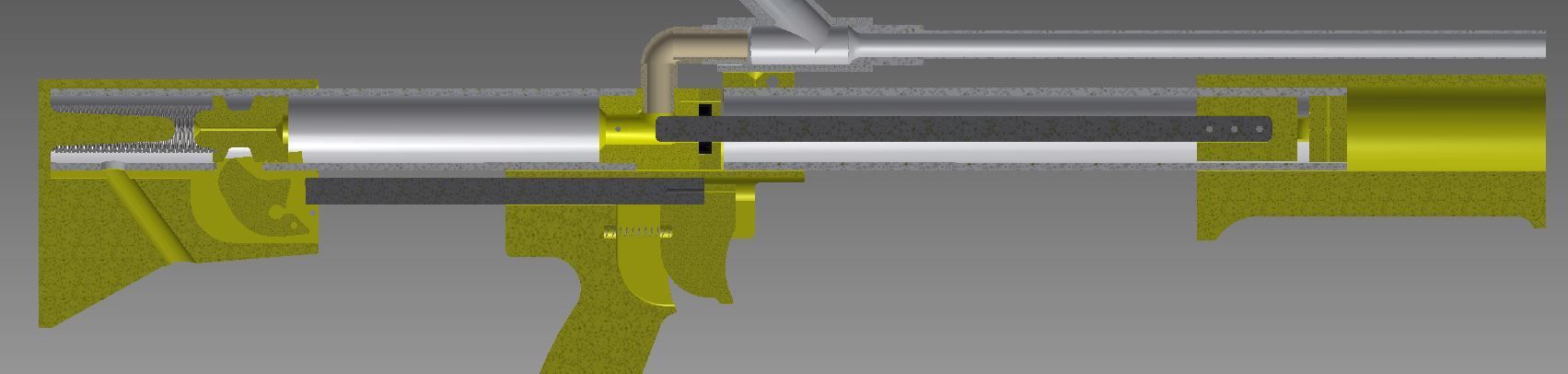

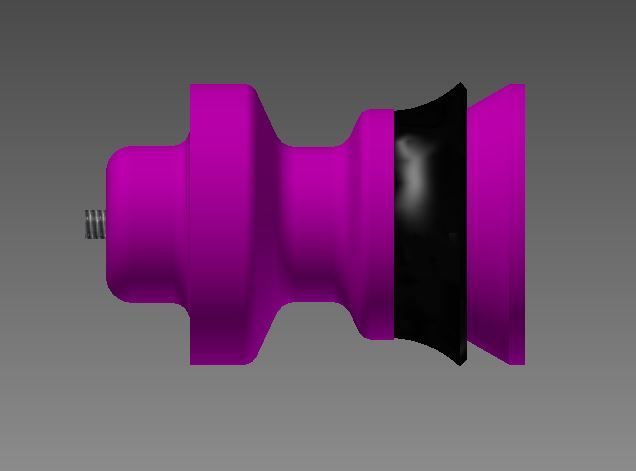

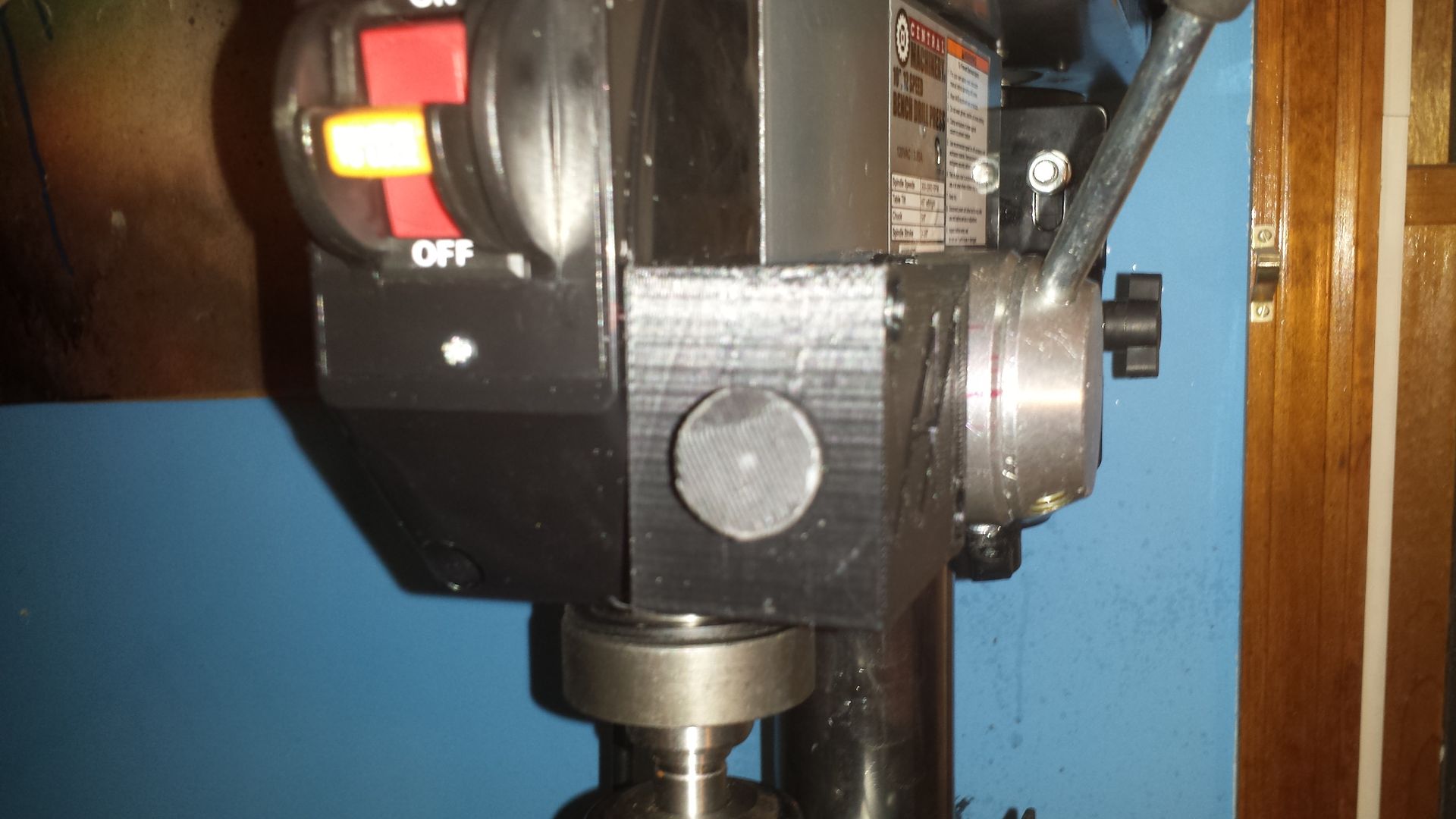

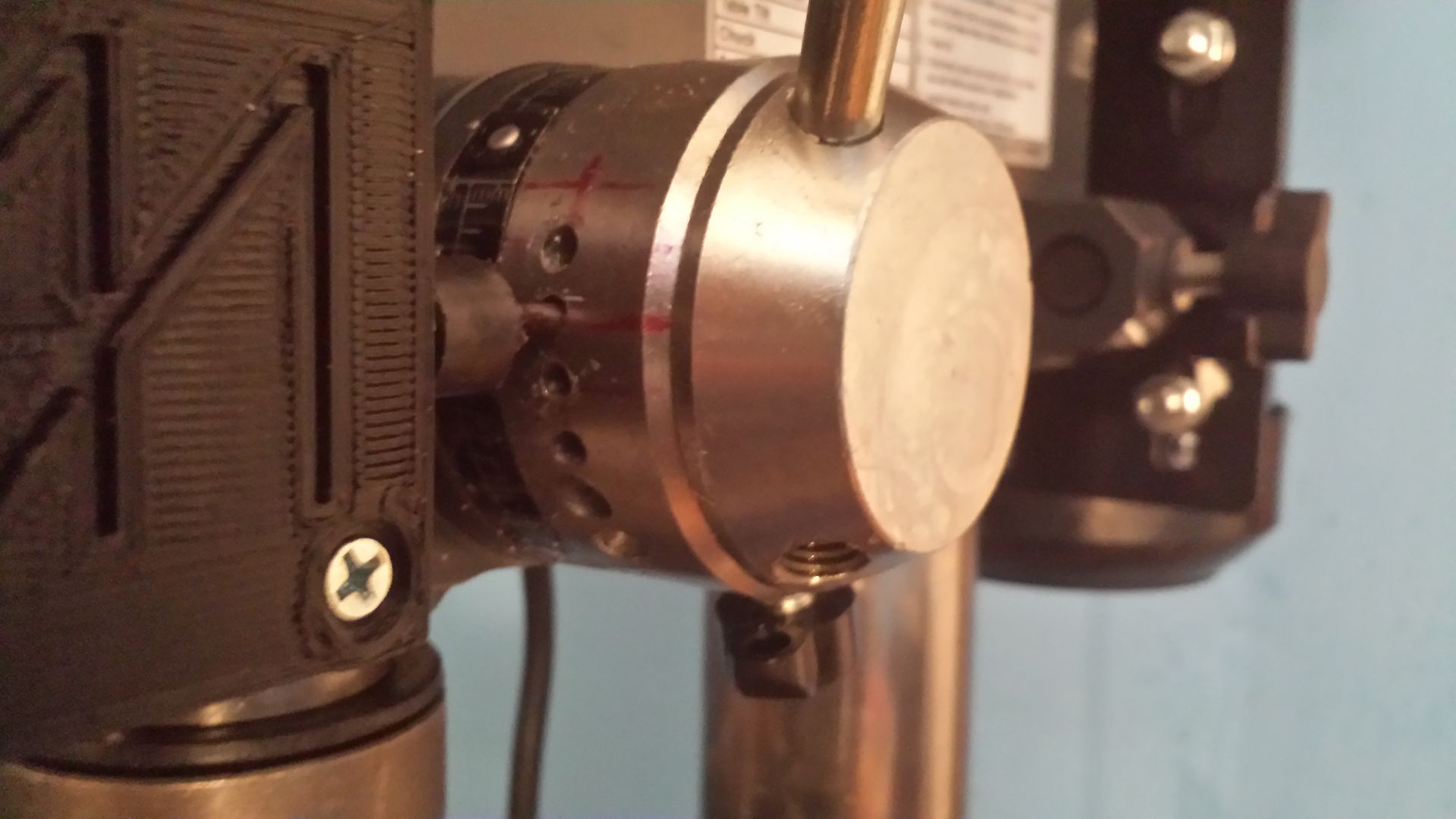

The screws on the thinwall actually don't take too much force. You have a snug fit with the electrical tape against the plunger tube, the back of the parasite is supported by the pistol grip itself, and the screws are really only to make sure the thing doesn't fly off the front and also prevents rotation. Plus I have four total, two on each side, so the force is fairly well distributed.

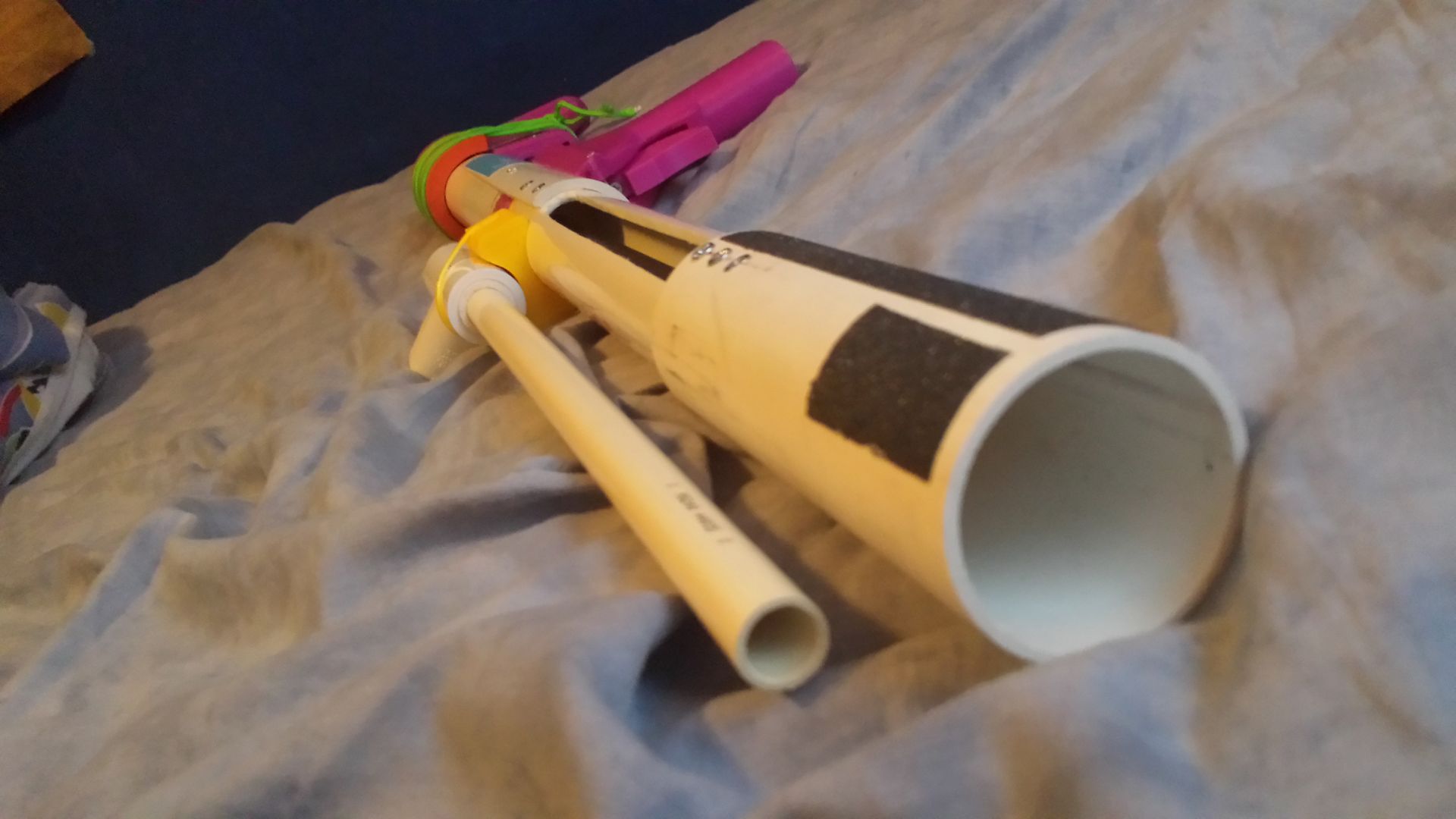

The palm trigger is only weird because it's not shaped very well. I need to make it a little bigger and then it will be fine. I was working on this for like five hours into the dark hours of the night and just wanted it done, so ergonomics was not sitting at the head of the class at the time.

5 shots by stuffing the entire barrel? This is pretty cool. Would want to see it hopped because why the fuck not, lmao. I think you can attatch a similar system to a rainbow pump, and I'm tempted to try now. Also, how do you plan on solving the hand ergonomics? I guess this is great for a gross motor skill under the stress when the finger no do the working.

I've hoppered rainbow pistols before, they get like slightly better than stock nitefinder ranges. The shotgun is where it's at for me. I just love shotguns. Future double barrel, anyone?

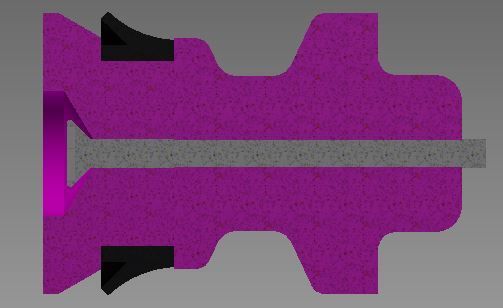

And this begs the question of, why hopper the thing at all? You already have a more than capable primary that has a relatively high ROF and hopper clip, what do you gain by adding a hopper to the parasite? The range wouldn't be as good, the ROF wouldn't be as good (assuming you're shouldering the blaster) and you don't gain anything the pullback doesn't already give you. I'd never run this as a single-shot. I run it as a shotgun because in the event you are reloading the main blaster, you have one more trick up your sleeve, you can panic-fire the parasite while reloading or rushing a capture point or something like that, and you get about a second of disorientation and a good spread to boot, so precise aiming isn't necessary. From ten yards my spread is about four feet with three darts, so it's hard to actually dodge. Add more darts and it becomes even more difficult.

The ergonomics are easy to solve, this was more of a proof of concept than anything else. A simple chamfer operation on the edges around the bottom would solve all the problems, and shaving off 1/8" or so from each side would take off some weight and make it easier to hold. Right now, you actually hold it from the tube, and slide your hand backwards, almost like a pump, when you want to fire. And as admitted previously, the palm trigger is a bit too small, Just need to shape a new one when I feel like it and it'll solve most of the problems I already mentioned. Still, it works and I'm happy with it, though I think the added weight as a secondary blaster will delegate this to the wall, This mounting method is better used for maybe panther tanks or foregrips on snap-bows or rainbow-bows.

Posted by

Posted by